Service Lubrication

Grease

The following greases are preferred:

· John Deere Multi-Purpose SD Polyurea Grease

· John Deere Multi-Purpose HD Lithium Complex Grease

· John Deere Moly High Temperature EP Grease

If not using any of the preferred greases, be sure to use a general all-purpose grease with an NLGI grade No.2 rating.

Wet or high speed conditions may require use of a special-use grease. Contact your Servicing dealer for information.

Lubricating Machine Grease Fittings

· Extremely Wet and Muddy Conditions - Lubricate machine grease fittings every 10 hours of operation or on a daily basis

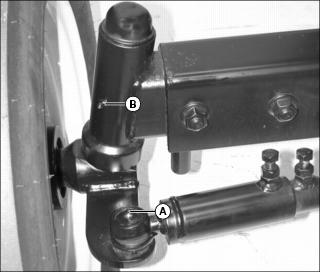

2WD Model Machines

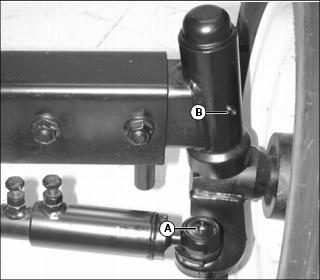

MFWD Model Machines

B - Left Steering Cylinder Ball Joint

B - Right Steering Cylinder Ball Joint

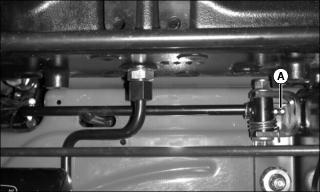

Gear Models

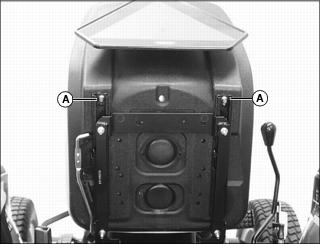

Lubricating Seat Slide Rails

2. Lubricate seat slide rails (A) with clean engine oil.

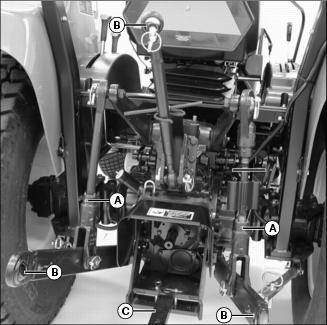

Lubricating 3-Point Hitch

· Lubricate lift link grease fittings (A) with a preferred John Deere grease or an equivalent.

· Lubricate ball joints (B) and draw bar (C) with clean engine oil.