Service

Service Intervals

Every 25 Hours

• Lubricate front anti-scalp wheels.

• Lubricate rear gauge wheels.

Every 50 Hours

Every 100 Hours

Every 500 Hours

Grease

The following greases are preferred:

• John Deere Multi-Purpose SD Polyurea Grease

• John Deere Multi-Purpose HD Lithium Complex Grease

• John Deere Moly High Temperature EP Grease

If not using any of the preferred greases, be sure to use a general all-purpose grease with an NLGI grade No.2 rating.

Wet or high speed conditions may require use of a special-use grease. Contact your Servicing dealer for information.

NOTE: Some types of grease thickeners are not compatible with others. Consult your grease supplier before mixing different types of grease.

Gear Oil

Use oil viscosity based on the expected air temperature range during the period between oil changes.

John Deere GL-5 Gear Lubricant is recommended.

Other oils may be used if they meet one or more of the following:

• API Service Classification GL-5.

• Military Specification MIL-L-2105D.

• Military Specification MIL-L-2105C.

• Military Specification MIL-L-2105B.

Oils meeting Military Specification MIL-L-10324A may be used as arctic oils.

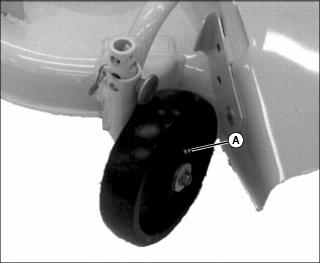

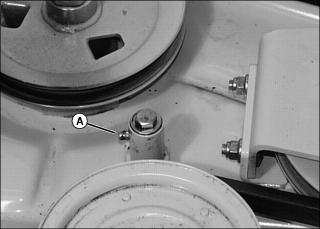

Lubricating Rear Gage Wheels

Lubricate rear wheel point (A) with one or two shots of John Deere multipurpose grease or an equivalent.

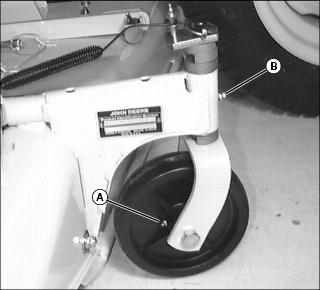

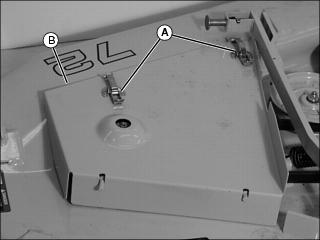

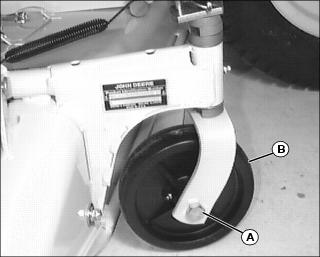

Lubricating Front Anti-Scalp Wheels

Lubricate each front anti-scalp wheel (A) and pivot bushing point (B) with one or two shots of John Deere Multipurpose grease or an equivalent.

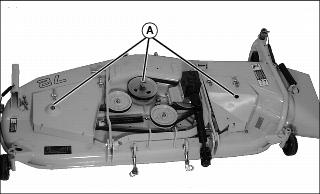

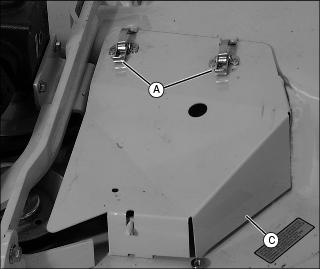

Lubricating Spindles

Lubricate three mower spindle points (A) with two shots of John Deere multi-purpose grease or equivalent.

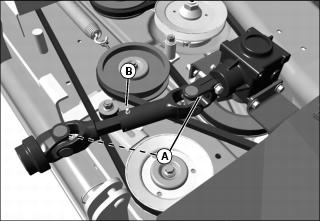

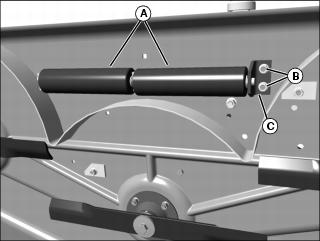

Lubricating Driveshaft

Lubricate U-joints (A) and shaft (B) with one or two shots of John Deere EP grease, or an equivalent.

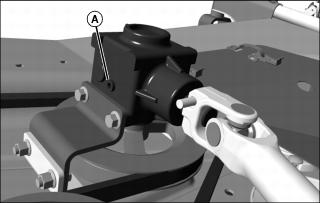

Lubricating Idler Arm Pivot

1. Park the machine safely. (See Parking Safely in the Safety section.)

3. Lubricate idler arm pivot (A) with one or two shots of John Deere multi-purpose grease or equivalent.

Removing Belt Shields

1. Park the machine safely. (See Parking Safely in the Safety section.)

Picture Note: Left side shown.

Picture Note: Right side shown.

3. Remove left (B) and right (C) belt shields.

Servicing Gearbox

Checking Gearbox Oil Level

1. Park the machine safely. (See Parking Safely in the Safety section.)

2. Remove check plug (A) from either side of gearbox.

3. Oil should be level with bottom of check plug hole.

4. If oil is low add oil specified until it runs out of check plug hole.

Changing Gearbox Oil

1. Park the machine safely. (See Parking Safely in the Safety section.)

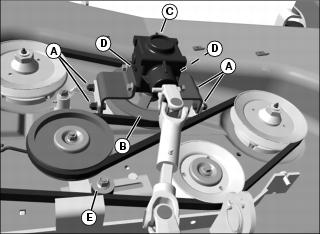

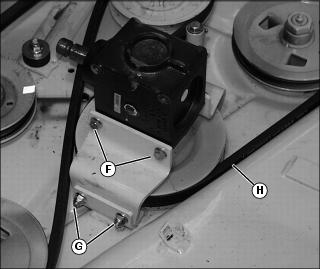

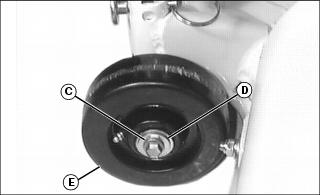

4. Remove nuts (A) from studs.

5. Remove belt from gearbox sheave (B). Remove mounting bracket and gearbox (C) as an assembly.

6. Remove both check plugs (D).

7. Turn gearbox on its side to drain oil.

8. Turn gearbox upright. Add oil as necessary until oil runs out of check plug hole.

9. Install and tighten check plugs (D).

10. Install gearbox assembly. Tighten nuts (A).

11. Install belt on gearbox sheave (B) and on all deck sheaves.

12. Adjust idler arm stop (E).

Adjusting Idler Stop

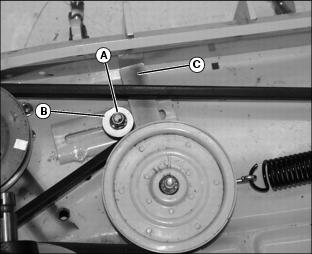

1. Loosen nut (A) on idler stop (B).

2. Put idler stop against idler arm (C) and tighten nut.

Servicing Mower Belt

1. Park the machine safely. (See Parking Safely in the Safety section.)

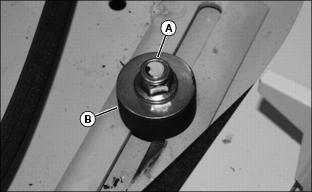

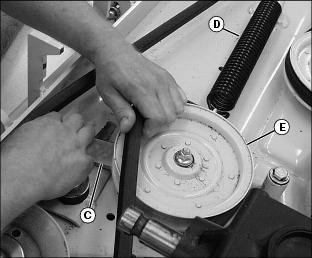

4. Loosen nut (A) on idler stop (B) and move away from idler arm.

5. With one hand carefully pull back on idler arm (C) to place tension on the spring (D), relaxing tension on the belt. At the same time carefully remove the belt while rotating the movable idler sheave (E).

6. Slowly return idler arm and spring back to its relaxed position.

7. Remove gearbox by removing hex head bolts (F) and locknuts (G).

IMPORTANT: Avoid damage! To prevent damage to mower belt, do not clean belt using a parts cleaning solvent or belt dressing. They soften belt and shorten belt life. |

9. Clean and inspect belt for damage. Replace belt if necessary.

10. Install new belt (I). Use illustration for belt routing.

11. Carefully pull back and hold idler arm (C) to release belt tension. Carefully install belt on the movable idler sheave (E).

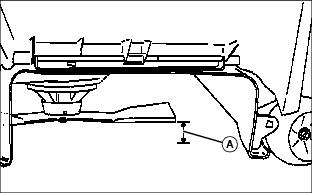

Checking for Bent Mower Blades

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Raise mower deck to highest position to access blades.

Picture Note: Mower deck with side discharge used for illustration

3. Measure distance (A) between blade tip and flat ground surface.

4. Rotate blade 180? and measure distance between other blade tip and flat ground surface.

5. Install new blade if the difference between the two measurements is more than 3 mm (1/8 in.).

Removing and Installing Blades

Removing Blades

1. Park the machine safely. (See Parking Safely in the Safety section.)

2. Remove mower deck from machine.

4. Insert wood block between blade and mower to prevent blade from turning when removing bolt.

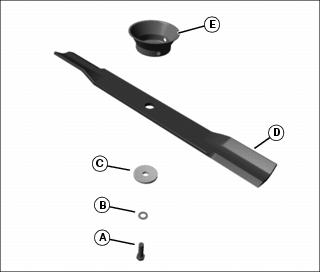

5. Loosen and remove bolt (A), washer (B), blade washer (C), blade (D) and deflector cup (E).

6. Inspect blades; sharpen, balance or replace as necessary.

Installing Blades

1. Install deflector cup (E) on spindle.

2. Position mower blade (D) with the cutting edge towards the ground on the mower spindle.

NOTE: Blade washer must be installed as shown. (Cupped upward.)

3. Install blade washer (C) with cupped side toward blade.

4. Install hardened washer (B).

5. Install bolt (A) by hand, until mower blade is in full contact (fully seated) with spindle.

6. With mower blade blocked, to prevent spinning, tighten bolt (A) to 102 - 124 N•m (75 - 94 lb-ft).

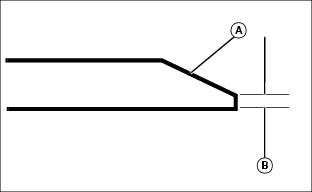

Sharpening Blades

• Sharpen blades with grinder, hand file, or electric blade sharpener.

• Keep original bevel (A) when grinding.

• Blade should have 0.40 mm (1/64 in.) cutting edge (B) or less.

• Balance blades before installing.

Balancing Blades

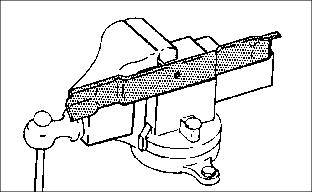

2. Put blade on nail in a vise. Turn blade to horizontal position.

3. Check balance. If blade is not balanced, heavy end of blade will drop.

4. Grind bevel of heavy end. Do not change blade bevel.

Replacing Wheels and Rollers

Front and Rear Wheels

1. Park the machine safely. (See Parking Safely in the Safety section.)

3. Pull depth control rockshaft lever to rear to fully raise mower deck.

5. Check front and rear wheels for excessive wobble. Replace wheels as necessary.

a. Remove bolt (A) and locknut.

c. Install new wheel, secure using bolt (A) and locknut.

a. Remove bolt (C) and washer (D).

c. Install new wheel, secure using bolt (C) and washer (D).

Front Roller

1. Park the machine safely. (See Parking Safely in the Safety section.)

Picture Note: Mower deck removed for photo clarity only.

2. Check roller (A) for wear and damage. Roller must turn freely and have no flat spots. Replace roller as necessary.

d. Install new roller. (See your John Deere dealer for replacement parts.)

e. Install roller shaft (C). Secure using flanged nut (B).

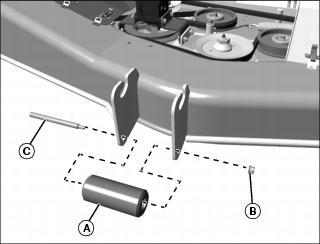

Rear Roller

1. Park the machine safely. (See Parking Safely in the Safety section.)

4. Check rollers (A) and support brackets for wear or damage. Rollers must turn freely and have no flat spots.

b. Remove shaft from brackets (C).