Service Transmission

Transaxle Oil

IMPORTANT: Avoid damage! Use recommended oil only. Do not use engine oil or "Type F" automatic transmission fluid. |

Use oil viscosity based on the expected air temperature range during the period between oil changes.

John Deere Low Viscosity HY-GARD Transmission/Hydraulic Oil is recommended. Standard John Deere HY-GARD Transmission/Hydraulic Oil may also be used.

Other oils may be used if they meet John Deere standard JDM J20C.

Checking Front Axle Oil Level

IMPORTANT: Avoid damage! Allow oil one hour to settle before checking level to ensure accurate dipstick reading. Repeat oil level check after several hours of operation. |

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Allow machine to cool down and oil to settle for at least one hour.

IMPORTANT: Avoid damage! Dirt and debris in oil may cause damage to the transaxle. Clean area around opening before removing dipstick. |

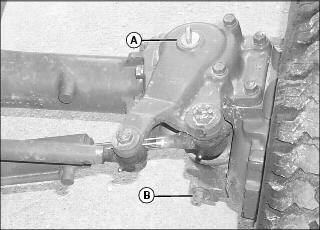

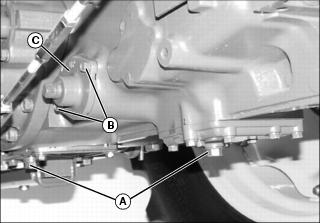

3. Loosen and remove dipstick (A) located on right side of front axle.

4. Wipe dipstick clean with a rag. Insert dipstick into axle hole but do not screw it into the axle case.

5. Remove dipstick. Oil level should be at top mark on dipstick. If oil level is low:

a. Add GL-5 Gear Lubricant® - SAE 80W-90 or equivalent through dipstick fill opening until oil level is correct.

b. Install and tighten dipstick.

6. Check front axle oil level again after the first several hours of operation.

Changing Front Axle Oil

1. Operate machine to warm front axle oil.

2. Park machine safely. (See Parking Safely in the SAFETY section.)

3. Remove dipstick (A) at right side of front axle or the fill plug at same location on left side of front axle.

NOTE: For draining purposes, front axle contains approximately 2.1 L (2.25 qt) of oil.

4. Positon drain pan under plug (B) at both sides of front axle. Remove plugs and allow oil to drain completely.

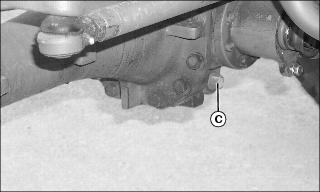

5. Position drain pan under differential drain plug (C). Remove plug and allow oil to drain completely.

6. Install and tighten drain plugs (B) and (C).

7. Add approximately 2.1 L (2.25 qts) of John Deere GL-5 Gear Lubricant or equivalent through dipstick or fill plug opening.

8. Install and tighten dipstick or fill plug.

IMPORTANT: Avoid damage! Allow oil one hour to settle before checking level to ensure accurate dipstick reading. Repeat oil level check after several hours of operation. |

9. Check front axle oil level.

Checking Transmission Oil Level

1. Park machine safely. (See Parking Safely in the SAFETY section.) Allow machine to cool down for at least one hour.

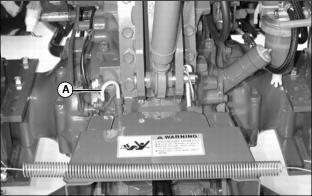

2. Remove dipstick (A) located behind seat. Wipe dipstick with a clean rag. Install dipstick and then remove to check oil level.

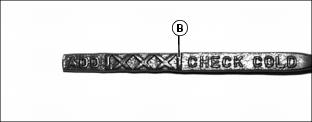

3. Oil level should be up to mark (B). Add oil if necessary.

4. Add John Deere Low Viscosity HY-GARD® (JDM J20D) or equivalent.

Changing Transmission Oil and Filter

1. Run engine a few minutes to warm the transmission oil.

2. Park machine safely. (See Parking Safely in the SAFETY section.)

NOTE: For draining purposes, the transmission contains approximately 21 L (5.5 gal) of oil.

3. Place a drain pan under either transmission drain plug (A). Remove the drain plug. Allow oil to drain completely.

4. After oil is drained, remove cap screws (B) and suction strainer cover (C) at right side of transmission.

5. Pull out suction screen inside of transmission housing.

6. Clean suction screen with a mild solvent. Allow to dry.

7. Install suction screen and cover. Secure with cap screws.

8. Place a drain pan under hydraulic oil filter (D) at left side of machine. Remove and discard filter. Allow residual oil to drain completely.

9. Put a film of clean transmission oil on seal of new filter.

10. Fill the filter 1/3 to 1/2 full with specified hydraulic oil.

11. Tighten filter quickly onto filter head until it contacts mounting surface. Tighten filter by hand an additional 1/2 turn.

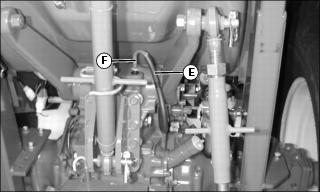

12. Remove hose (E) attached to vent tube (F) located behind operator's seat.

13. Turn vent tube counter-clockwise to remove.

14. Clean vent tube with a mild solvent. Allow to dry.

17. Add approximately 21 L (5.5 gal) of John Deere Low Viscosity HY-GARD® (JDM J20D) or equivalent through fill opening. Install fill cap.

18. Start engine. Check for oil leaks around filter base and drain plug.