Service

Service Intervals

Before Each Use

Every 25 Hours

• Check and clean auger gearbox vent hole

• Check auger gearbox oil level

• Check snowblower gearbox oil level

Grease

The following greases are preferred:

• John Deere Multi-Purpose SD Polyurea Grease

• John Deere Multi-Purpose HD Lithium Complex Grease

If not using any of the preferred greases, be sure to use a general all-purpose grease with an NLGI grade No.2 rating.

Wet or high speed conditions may require use of a special-use grease. Contact your Servicing dealer for information.

Gear Oil

Use oil viscosity based on the expected air temperature range during the period between oil changes.

John Deere GL-5 Gear Lubricant is recommended.

Other oils may be used if they meet one or more of the following:

• API Service Classification GL-5.

• Military Specification MIL-L-2105D.

• Military Specification MIL-L-2105C.

• Military Specification MIL-L-2105B.

Oils meeting Military Specification MIL-L-10324A may be used as arctic oils.

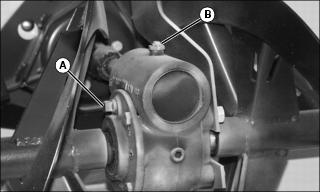

Checking Auger Gearbox Oil Level

1. Park tractor safely. (See Parking Safely in SAFETY Section of tractor operator’s manual.)

IMPORTANT: Avoid damage! Check cross hole vent in fill plug when checking oil level. Vent hole must be clear of obstructions or pressure will build in gearbox and cause gearbox to leak. |

3. Oil should be level with check plug hole.

4. Remove fill plug (B), if oil is low.

6. Install and tighten fill plug and check plug.

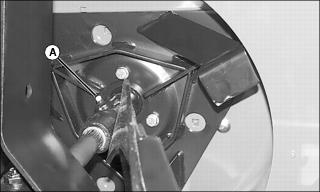

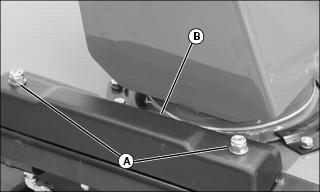

Checking Snowblower Gearbox Oil Level

1. Park tractor safely. (See Parking Safely in SAFETY Section of tractor operator’s manual.)

2. Remove one of the check plugs (A).

3. Oil should be level with hole.

4. Add recommended gear oil as needed.

Lubricating

1. Park tractor safely. (See Parking Safely in SAFETY Section of tractor operator’s manual.)

2. Lubricate grease fittings with recommended grease:

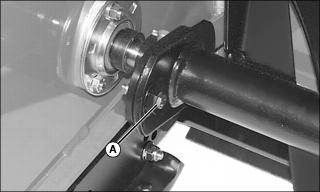

Gearbox Driveshaft

Lubricate fitting (A) with one or two shots of grease.

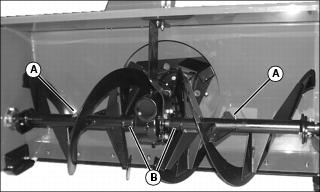

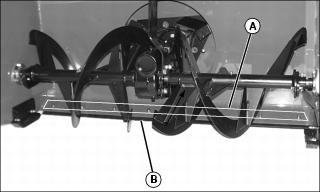

Auger Shaft

Lubricate fittings(A) with grease. Apply grease until it just comes out of auger shafts (B) at gearbox.

Discharge Chute and Cable Pulleys

• Apply grease under chute before every use.

• Apply light grease to cable pulleys.

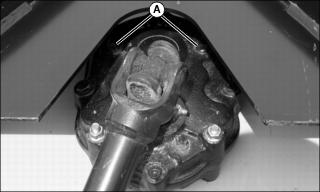

Driveshaft

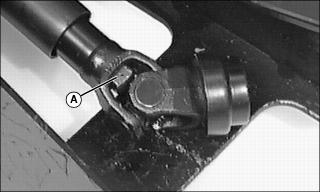

• Lubricate all U-joint fittings with one or two shots of grease.

• Lubricate inner shaft (A) with grease. Extend and compress driveshaft several times to distribute grease.

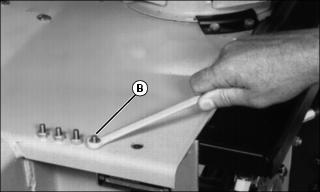

Replacing Shear Bolt

NOTE: A shear bolt (A) is installed in each end of auger shaft. The shear bolt will break if attachment hits a solid object. This will protect the auger and attachment from serious damage.

1. If you hit a solid object, stop attachment immediately.

2. Stop engine. Lock park brake. Lower attachment.

3. Find and correct cause for shearing.

4. Remove shear bolt (B) stored in auger housing.

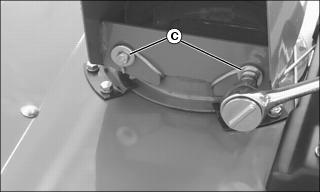

Replacing Discharge Chute Cable

2. Turn chute completly to left. Hydraulic cylinder should be completely retracted.

3. Park tractor safely. (See Parking Safely in SAFETY Section of tractor operator’s manual.)

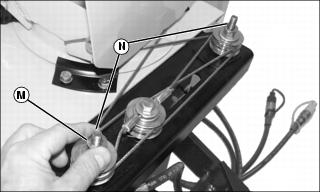

4. Remove two stop nuts, washers (A), and cable shield (B). Remove two washers from threaded studs.

6. Disconnect cable ends from chute.

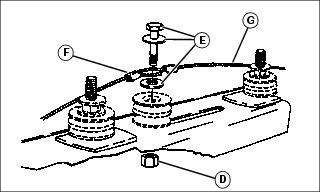

7. Remove nut (D), bolt and washers (E).

8. Remove cable ends (F) and (G) from pulleys. Remove cable assembly.

9. Install new cable so longer cable end (F) is to the left and shorter cable end (G) is to the right.

10. Install bolt and washers (E) in cable assembly eyelet. Install nut (D).

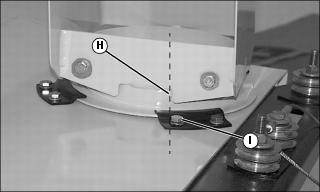

11. Move chute so tab (H) on chute is in line with edge of capscrew (I). Chute opening will be on the left.

13. Use locking pliers to pull cable tight.

b. Around bottom center pulley.

c. Around bottom right pulley.

16. Use locking pliers to pull cable tight.

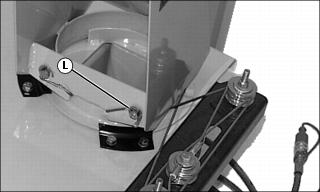

18. Install a washer (M) on each cable shield bolt (N).

19. Install cable shield, two washers, and stop nuts.

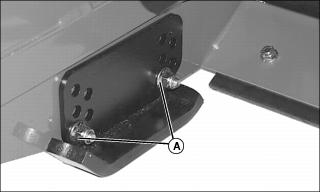

Replacing Skid Shoes

2. Put blocks under scraper blade on both sides of snowblower.

4. Stop engine and remove key.

5. Lower snowblower onto blocks.

6. Remove nuts (A) and bolts from skid shoe.

NOTE: Both skid shoes must be installed in same position.

7. Install new skid shoe bolts and nuts.

Reversing or Replacing Scraper Blade

NOTE: Reverse the blade when one edge becomes worn, rough, or bent. If both edges are worn, rough, or bent, replace the blade.

2. Put blocks under both sides of snowblower.

4. Stop engine and remove key.

5. Lower snowblower onto blocks.

6. Remove eight nuts (A) and bolts.

8. Rotate blade so rear edge of blade is at front.

9. Install blade with bolts and nuts.

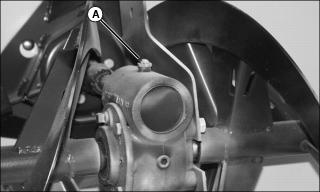

Cleaning Gearbox Air Vent

1. Park tractor safely. (See Parking Safely in SAFETY Section of tractor operator’s manual.)

IMPORTANT: Avoid damage! Vent hole must be clear of obstructions or pressure will build in gearbox and cause gearbox to leak. |

2. Check vent hole (A) in fill plug to make sure it is not plugged with dirt or debris.

3. Clean the vent hole periodically to remove dirt.

• Remove the fill plug and clean vent hole with solvent if needed.