Service

Service Intervals

NOTE: If you use backhoe for more than 10 hours daily, lubricate all points listed above twice a day.

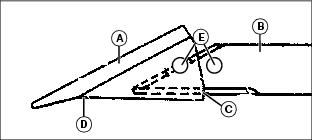

Replacing Bucket Teeth

1. Remove tooth (A) from shank (B):

• When tooth is loose, hit area (D) with hammer.

4. Peen area (E) on each side.

Cleaning Inside Valve Covers

1. Remove four bolts (A). Remove cover.

Lubrication

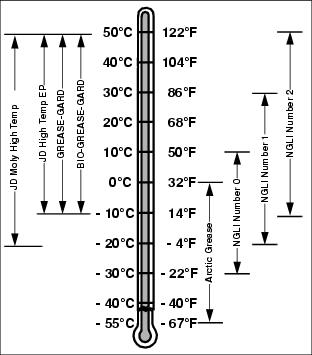

Grease

Use grease based on the expected air temperature range during the service interval.

The following greases are preferred:

• John Deere Moly High Temperature EP Grease.

• John Deere High Temperature EP Grease.

Other greases may be used are:

• SAE Multipurpose EP Grease with 3 to 5 percent molybdenum disulfide.

• Greases meeting Military Specification MIL-G-10924C may be used as arctic grease.

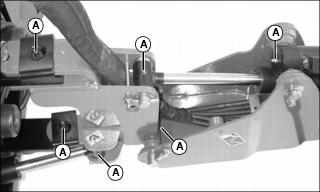

NOTE: Lubricate grease fittings as shown. Lubricate all other pivot points with SAE-10 oil.

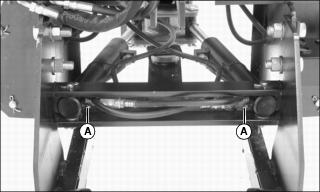

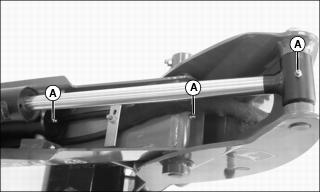

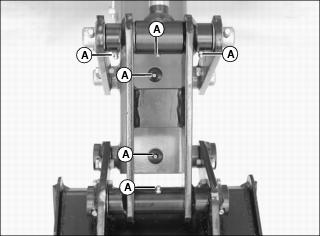

Model 46

1. Lubricate grease fittings (A) with John Deere multipurpose grease or an equivalent.