Safety

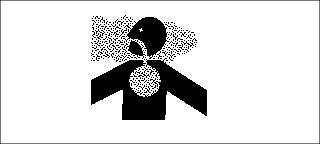

Recognize Safety Information

This is a safety-alert symbol. When you see this symbol on your machine or in this manual, be alert to the potential for personal injury.

Follow recommended precautions and safe operating practices.

Understand Signal Words

A signal word-DANGER, WARNING, or CAUTION-is used with the safety-alert symbol. DANGER identifies the most serious hazards.

DANGER or WARNING safety signs are located near specific hazards. General precautions are listed on CAUTION safety signs. CAUTION also calls attention to safety messages in this manual.

Follow Safety Instructions

Carefully read all safety messages in this manual and on your machine safety signs. Keep safety signs in good condition. Replace missing or damaged safety signs. Be sure new equipment components and repair parts include the current safety signs. Replacement safety signs are available from your John Deere dealer.

There can be additional safety information contained on parts and components sourced from suppliers that is not reproduced in this operator’s manual.

Learn how to operate the machine and how to use controls properly. Do not let anyone operate without instruction.

Keep your machine in proper working condition. Unauthorized modifications to the machine may impair the function and/or safety and affect machine life.

If you do not understand any part of this manual and need assistance, contact your John Deere dealer.

Prepare for Emergencies

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service, hospital, and fire department near your telephone.

Wear Protective Clothing

Wear close fitting clothing and safety equipment appropriate to the job.

Operating equipment safely requires the full attention of the operator. Do not wear radio or music headphones while operating machine.

Protect Against Noise

Prolonged exposure to loud noise can cause impairment or loss of hearing.

Wear a suitable hearing protective device such as earmuffs or earplugs to protect against objectionable or uncomfortable loud noises.

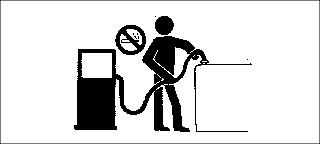

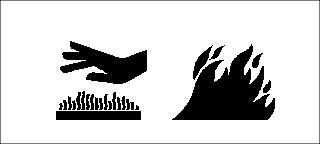

Handle Fuel Safely - Avoid Fires

Handle fuel with care: it is highly flammable. Do not refuel the machine while smoking or when near open flame or sparks.

Always stop engine before refueling machine. Fill fuel tank outdoors.

Prevent fires by keeping machine clean of accumulated trash, grease, and debris. Always clean up spilled fuel.

Use only an approved fuel container for transporting flammable liquids.

Never fill fuel container in pickup truck with plastic bed liner. Always place fuel container on ground before refueling. Touch fuel container with fuel dispenser nozzle before removing can lid. Keep fuel dispenser nozzle in contact with fuel container inlet when filling.

Do not store fuel container where there is an open flame spark, or pilot light such as within a water heater or other appliance.

Handle Starting Fluid Safely

Starting fluid is highly flammable.

Keep all sparks and flame away when using it. Keep starting fluid away from batteries and cables.

To prevent accidental discharge when storing the pressurized can, keep the cap on the container, and store in a cool, protected location.

Do not incinerate or puncture a starting fluid container.

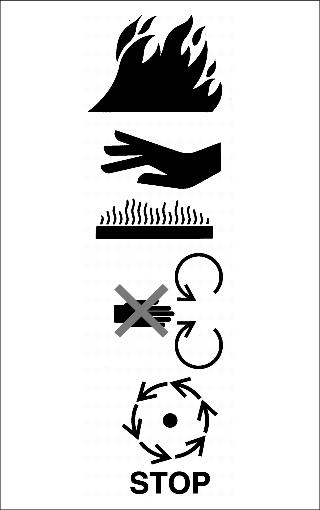

In Case of Fire

Stop machine operation immediately at first sign of fire. Fire may be indicated by smell of smoke or sight of smoke or flames.

If fire can be safely extinguished, proceed carefully following the instructions on your fire extinguisher. If your extinguisher does not have instructions, carefully follow these general guidelines:

1. Remove fire extinguisher from bracket.

2. Cautiously approach area of fire with wind to your back.

3. Pull safety pin from extinguisher.

4. Hold extinguisher by handles and aim hose at base of flames.

5. Squeeze handles to discharge extinguisher.6. Move nozzle back and forth, covering flames with extinguishing agent.

Fire Prevention

To reduce the risk of fire, your tractor should be regularly inspected and cleaned.

• Birds and other animals may build nests or bring other flammable materials into the engine compartment or onto the exhaust system. The tractor should be inspected and cleaned prior to the first use each day.

• A build up of grass, crop material and other debris may occur during normal operation. This is especially true when operating in very dry conditions or conditions where airborne crop material or crop dust is present. Any such build up must be removed to ensure proper machine function and to reduce the risk of fire. The tractor must be inspected and cleaned periodically throughout the day.

• Regular and thorough cleaning of the tractor combined with other routine maintenance procedures listed in the Operator’s Manual greatly reduce the risk of fire and the chance of costly downtime.

• Do not store fuel container where there is an open flame, spark, or pilot light such as within a water heater or other appliance.

• Check fuel lines, tank, cap, and fittings frequently for damage, cracks or leaks. Replace if necessary.

Follow all operational and safety procedures posted on the machine and the Operator’s Manual. Be careful of hot engine and exhaust components during inspection and cleaning. Before carrying out any inspection or cleaning, always shut OFF the engine, place the transmission in PARK or set parking brake, and remove the key. Removal of the key will prevent others from starting the tractor during inspection and cleaning.

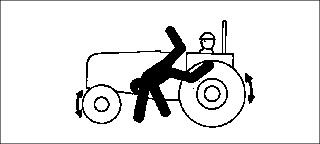

Keep ROPS Installed Properly

Make certain all parts are reinstalled correctly if the roll-over protective structure (ROPS) is loosened or removed for any reason. Tighten mounting bolts to proper torque.

The protection offered by ROPS will be impaired if ROPS is subjected to structural damage, is involved in an overturn incident, or is in any way altered by welding, bending, drilling, or cutting. A damaged ROPS should be replaced, not reused.

The seat is part of the ROPS safety zone. Replace only with John Deere seat approved for your tractor.

Any alteration of the ROPS must be approved by the manufacturer.

Use Foldable ROPS and Seat Belt Properly

If this tractor is equipped with a foldable ROPS, keep the ROPS in the fully extended and locked position. If the tractor is ever operated with ROPS folded (e.g., to enter a low building), drive with extreme caution. Do NOT use seat belt with the ROPS folded.

Return the ROPS to the raised, fully extended and locked position as soon as the tractor is operated under normal conditions. Always fasten your seat belt when the ROPS is fully extended and locked.

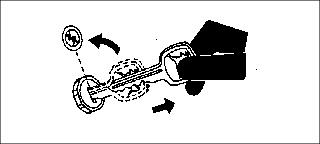

Stay Clear of Rotating Drivelines

Entanglement in rotating driveline can cause serious injury or death.

Keep tractor master shield and driveline shields in place at all times. Make sure rotating shields turn freely.

Wear close fitting clothing. Stop the engine and be sure PTO driveline is stopped before making adjustments, connections, or cleaning out PTO driven equipment.

Do not install any adapter device between the tractor and the primary implement PTO drive shaft that will allow a 1000 rpm tractor shaft to power a 540 rpm implement at speeds higher than 540 rpm.

Do not install any adapter device that results in a portion of the rotating implement shaft, tractor shaft, or the adapter to be unguarded. The tractor master shield shall overlap the end of the splined shaft and the added adaptor device as outlined in the table.

Use Steps and Handholds Correctly

Prevent falls by facing the machine when getting on and off. Maintain 3-point contact with steps and handrails. Never use machine controls as handholds.

Use extra care when mud, snow, or moisture present slippery conditions. Keep steps clean and free of grease or oil. Never jump when exiting machine. Never mount or dismount a moving machine.

Read Operator Manuals for ISOBUS Implements

In addition to GreenStar Applications, this display can be used as a display device for any implement that meets ISO 11783 standard. This includes capability to control ISOBUS implements. When used in this manner, information and implement control functions placed on the display are provided by the implement and are the responsibility of the implement manufacturer. Some of these implement functions could provide a hazard either to the Operator or a bystander. Read the operator manual provided by the implements manufacturer and observe all safety messages in manual and on implement prior to use.

NOTE: ISOBUS refers to the ISO Standard 11783.

Use Seat Belt Properly

Use a seat belt when you operate with a roll-over protective structure (ROPS) or cab to minimize chance of injury from an accident such as an overturn.

Do not use a seat belt if operating without a ROPS or cab.

Replace entire seat belt if mounting hardware, buckle, belt, or retractor show signs of damage.

Inspect seat belt and mounting hardware at least once a year. Look for signs of loose hardware or belt damage, such as cuts, fraying, extreme or unusual wear, discoloration, or abrasion. Replace only with replacement parts approved for your machine. See your John Deere dealer.

Operating the Tractor Safely

You can reduce the risk of accidents by following these simple precautions:

• Use your tractor only for jobs it was designed to perform, for example, pushing, pulling, towing, actuating, and carrying a variety of interchangeable equipment designed to conduct agricultural work.

• This tractor is not intended to be used as a recreational vehicle.

• Read this operator’s manual before operating the tractor and follow operating and safety instructions in the manual and on the tractor.

• Follow operation and ballasting instructions found in the operator’s manual for your implements/attachments, such as front loaders

• Make sure that everyone is clear of machine, attached equipment, and work area before starting engine or operation.

• Keep hands, feet, and clothing away from power-driven parts.

Driving Concerns

• Never get on or off a moving tractor.

• Keep all children and nonessential personnel off tractors and all equipment.

• Never ride on a tractor unless seated on a John Deere approved seat with seat belt.

• Keep all shields/guards in place.

• Use appropriate visual and audible signals when operating on public roads.

• Move to side of road before stopping.

• Reduce speed when turning, applying individual brakes, or operating around hazards on rough ground or steep slopes.

• Couple brake pedals together for road travel.

• Pump brakes when stopping on slippery surfaces.

Towing Loads

• Be careful when towing and stopping heavy loads. Stopping distance increases with speed and weight of towed loads, and on slopes. Towed loads with or without brakes that are too heavy for the tractor or are towed too fast can cause loss of control.

• Consider the total weight of the equipment and its load.

• Hitch towed loads only to approved couplings to avoid rearward upset.

Parking and Leaving the Tractor

• Before dismounting, shut off SCVs, disengage PTO, stop engine, lower implements/attachments to ground and securely engage park mechanism, including the park pawl and park brake. In addition, if tractor is left unattended, remove key.

• Leaving transmission in gear with engine off will NOT prevent the tractor from moving.

• Never go near an operating PTO or an operating implement.

• Wait for all movement to stop before servicing machinery.

Unsafe operation or misuse of the tractor can result in accidents. Be alert to hazards of tractor operation.

The most common accidents involving tractors:

• Collisions with motor vehicles

• Improper starting procedures

• Crushing and pinching during hitching

Avoid Backover Accidents

Before moving machine, be sure that all persons are clear of machine path. Turn around and look directly for best visibility. Use a signal person when backing if view is obstructed or when in close quarters.

Do not rely on a camera to determine if personnel or obstacles are behind the machine. The system can be limited by many factors including maintenance practices, environmental conditions, and operating range.

Limited Use in Forestry Operation

The intended use of John Deere tractors when used in forestry operations is limited to tractor-specific applications like transport, stationary work such as log splitting, propulsion, or operating implements with PTO, hydraulic, or electrical systems.

These are applications where normal operation does not present a risk of falling or penetrating objects. Any forestry applications beyond these applications, such as forwarding and loading, requires fitment of application-specific components including Falling Object Protective Structure (FOPS) and/or Operative Protective Structures (OPS). Contact John Deere dealer for special components.

Operating the Loader Tractor Safely

When operating a machine with a loader application, reduce speed as required to ensure good tractor and loader stability.

To avoid tractor rollover and damage to front tires and tractor, do not carry load with your loader at a speed over 10 km/h (6 mph).

To avoid tractor damage do not use a front loader or a sprayer tank if the tractor is equipped with a 3 Meter Front Axle.

Never allow anyone to walk or work under a raised loader.

Do not use loader as a work platform.

Do not lift or carry anyone on loader, in bucket, or on implement or attachment.

Lower loader to ground before leaving operators station.

The Rollover Protective Structure (ROPS) or cab roof, if equipped, may not provide sufficient protection from load falling onto the operators station. To prevent loads from falling onto the operators station, always use appropriate implements for specific applications (that is, manure forks, round bale forks, round bale grippers, and clampers).

Keep Riders Off Machine

Only allow the operator on the machine. Keep riders off.

Riders on machine are subject to injury such as being struck by foreign objects and being thrown off of the machine. Riders also obstruct the operator's view resulting in the machine being operated in an unsafe manner.

Instructional Seat

The instructional seat, if so equipped, has been provided only for training operators or diagnosing machine problems.

Use Safety Lights and Devices

Prevent collisions between other road users, slow moving tractors with attachments or towed equipment, and self-propelled machines on public roads. Frequently check for traffic from the rear, especially in turns, and use turn signal lights.

Use headlights, flashing warning lights, and turn signals day and night. Follow local regulations for equipment lighting and marking. Keep lighting and marking visible, clean, and in good working order. Replace or repair lighting and marking that has been damaged or lost. An implement safety lighting kit is available from your John Deere dealer.

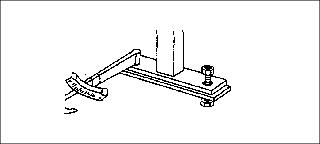

Use a Safety Chain

A safety chain will help control drawn equipment should it accidentally separate from the drawbar.

Using the appropriate adapter parts, attach the chain to the tractor drawbar support or other specified anchor location. Provide only enough slack in the chain to permit turning.

See your John Deere dealer for a chain with a strength rating equal to or greater than the gross weight of the towed machine. Do not use safety chain for towing.

Transport Towed Equipment at Safe Speeds

Do not exceed the maximum transport speed. This tractor is capable of operating at transport speeds that exceed the maximum allowable transport speed for most towed implements.

Before transporting a towed implement, determine from signs on the implement or information provided in the implement's operator manual the maximum transport speed. Never transport at speeds that exceed the implement's maximum transport speed. Exceeding the implement's maximum transport speed can result in:

• Loss of control of the tractor/implement combination

• Reduced or no ability to stop during braking

• Damage to the implement structure or its components

Implements without brakes:

• Do not transport at speeds greater than 32 km/h (20 mph).

• Must weigh less than 1.5 times the tractor weight and less than 1.5 t (3300 lb) when fully loaded.

Implements with brakes:

• If the manufacturer does not specify a maximum transport speed, do not tow at speeds greater than 40 km/h (25 mph).

• When transporting at speeds up to 40 km/h (25 mph) the fully loaded implement must weigh less than 4.5 times the tractor weight.

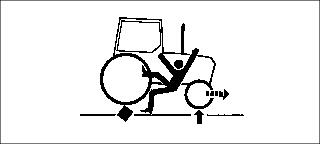

Use Caution On Slopes and Uneven Terrain

Avoid holes, ditches, and obstructions which cause the tractor to tip, especially on slopes. Avoid sharp uphill turns.

Driving forward out of a ditch, mired condition, or up a steep slope could cause tractor to tip over rearward. Back out of these situations if possible.

Danger of overturn increases greatly with narrow tread setting, at high speed.

Not all conditions that can cause a tractor to overturn are listed. Be alert for any situation in which stability may be compromised.

Slopes are a major factor related to loss-of-control and tip-over accidents, which can result in severe injury or death. Operation on all slopes requires extra caution.

Never drive near the edge of a gully, drop-off, ditch, steep embankment, or a body of water. The machine could suddenly roll over if a wheel goes over the edge or the ground caves in.

Choose a low ground speed so you will not have to stop or shift while on a slope.

Avoid starting, stopping or turning on a slope. If the tires lose traction, disengage the PTO and proceed slowly, straight down the slope.

Keep all movement on slopes slow and gradual. Do not make sudden changes in speed or direction, which could cause the machine to roll over.

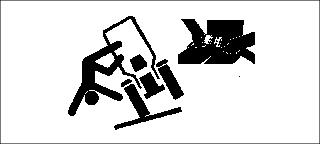

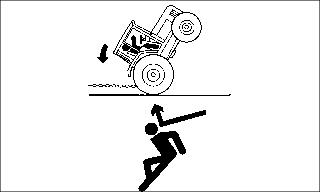

Freeing a Mired Machine

Attempting to free a mired machine can involve safety hazards such as the mired tractor tipping rearward, the towing tractor overturning, and the tow chain or tow bar (a cable is not recommended) failing and recoiling from its stretched condition.

Back your tractor out if it gets mired down in mud. Unhitch any towed implements. Dig mud from behind the rear wheels. Place boards behind the wheels to provide a solid base and try to back out slowly. If necessary, dig mud from the front of all wheels and drive slowly ahead.

If necessary to tow with another unit, use a tow bar or a long chain (a cable is not recommended). Inspect the chain for flaws. Make sure all parts of towing devices are of adequate size and strong enough to handle the load.

Always hitch to the drawbar of the towing unit. Do not hitch to the front pushbar attachment point. Before moving, clear the area of people. Apply power smoothly to take up the slack: a sudden pull could snap any towing device causing it to whip or recoil dangerously.

Avoid Contact with Agricultural Chemicals

This enclosed cab does not protect against inhaling harmful pesticides. If pesticide use instructions require respiratory protection, wear an appropriate respirator inside the cab.

Before leaving the cab, wear personal protective equipment as required by the pesticide use instructions. When re-entering the cab, remove protective equipment and store either outside the cab in a closed box or some other type of sealable container or inside the cab in a pesticide resistant container, such as a plastic bag.

Clean your shoes or boots to remove soil or other contaminated particles prior to entering the cab.

Handle Agricultural Chemicals Safely

Chemicals used in agricultural applications such as fungicides, herbicides, insecticides, pesticides, rodenticides, and fertilizers can be harmful to your health or the environment if not used carefully.

Always follow all label directions for effective, safe, and legal use of agricultural chemicals.

Reduce risk of exposure and injury:

• Wear appropriate personal protective equipment as recommended by the manufacturer. In the absence of manufacturer's instructions, follow these general guidelines:

• Chemicals labeled 'Danger': Most toxic. Generally require use of goggles, respirator, gloves, and skin protection.

• Chemicals labeled 'Warning': Less toxic. Generally require use of goggles, gloves, and skin protections.

• Chemicals labeled 'Caution': Least toxic. Generally require use of gloves and skin protection.

• Avoid inhaling vapor, aerosol or dust.

• Always have soap, water, and towel available when working with chemicals. If chemical contacts skin, hands, or face, wash immediately with soap and water. If chemical gets into eyes, flush immediately with water.

• Wash hands and face after using chemicals and before eating, drinking, smoking, or urination.

• Do not smoke or eat while applying chemicals.

• After handling chemicals, always bathe or shower and change clothes. Wash clothing before wearing again.

• Seek medical attention immediately if illness occurs during or shortly after use of chemicals.

• Keep chemicals in original containers. Do not transfer chemicals to unmarked containers or to containers used for food or drink.

• Store chemicals in a secure, locked area away from human or livestock food. Keep children away.

• Always dispose of containers properly. Triple rinse empty containers and puncture or crush containers and dispose of properly.

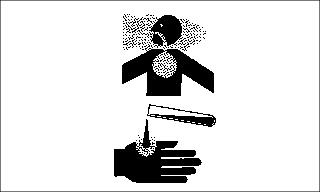

Handling Batteries Safely

Battery gas can explode. Keep sparks and flames away from batteries. Use a flashlight to check battery electrolyte level.

Never check battery charge by placing a metal object across the posts. Use a voltmeter or hydrometer.

Always remove grounded (-) battery clamp first and replace grounded clamp last.

Sulfuric acid in battery electrolyte is poisonous and strong enough to burn skin, eat holes in clothing, and cause blindness if splashed into eyes.

Avoid the hazard by:

• Filling batteries in a well-ventilated area.

• Wearing eye protection and rubber gloves.

• Avoiding use of air pressure to clean batteries.

• Avoiding breathing fumes when electrolyte is added.

• Avoiding spilling or dripping electrolyte.

• Using correct battery booster or charger procedure.

If you spill acid on yourself:

1. Flush your skin with water.

2. Apply baking soda or lime to help neutralize the acid.

3. Flush your eyes with water for 15-30 minutes. Get medical attention immediately.

If acid is swallowed:

2. Drink large amounts of water or milk, but do not exceed 2 L (2 quarts).

3. Get medical attention immediately.

WARNING: Battery posts terminals, and related accessories contain lead and lead compounds, chemicals knows to the State of California to cause cancer and reproductive harm. Wash hands after handling.

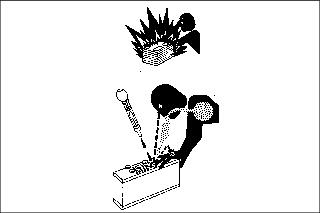

Avoid Heating Near Pressurized Fluid Lines

Flammable spray can be generated by heating near pressurized fluid lines, resulting in severe burns to yourself and bystanders. Do not heat by welding, soldering or using a torch near pressurized fluid lines or other flammable materials. Pressurized lines can be accidently cut when heat goes beyond the immediate flame area.

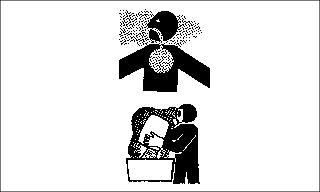

Remove Paint Before Welding or Heating

Avoid potentially toxic fumes and dust.

Hazardous fumes can be generated when paint is heated by welding, soldering, or using a torch.

• Remove paint a minimum of 100 mm (4 in.) from areas be affected by heating. If paint cannot be removed, wear an approved respirator before heating or welding.

• If you sand or grind paint, avoid breathing the dust. Wear an approved respirator.

• If you use solvent or paint stripper, remove stripper with soap and water before welding. Remove solvent or paint stripper containers and other flammable material from area. Allow fumes to dispense at least 15 minutes before welding or heating.

Do not use a chlorinated solvent in areas where welding will take place.

Do all work in an area that is ventilated to carry toxic fumes and dust away.

Dispose of paint and solvent properly.

Handle Electronic Components and Brackets Safely

Falling while installing or removing electronic components mounted on equipment can cause serious injury. Use a ladder or platform to easily reach each mounting location. Use sturdy and secure footholds and handholds. Do not install or remove components in wet or icy conditions.

If installing or servicing a RTK base station on a tower or other tall structure, use a certified climber.

If installing or servicing a global positioning receiver mast used on an implement, use proper lifting techniques and wear proper protective equipment. The mast is heavy and can be awkward to handle. Two people are required when mounting locations are not accessible from the ground or from a service platform.

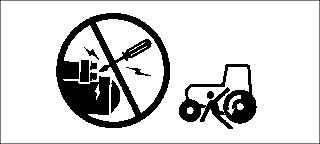

Practice Safe Maintenance

Understand service procedure before doing work. Keep area clean and dry.

Never lubricate, service, or adjust machine while it is moving. Keep hands, feet, and clothing from power-driven parts. Disengage all power and operate controls to relieve pressure. Lower equipment to the ground. Stop the engine. Remove the key. Allow machine to cool.

Securely support any machine elements that must be raised for service work.

Keep all parts in good condition and properly installed. Fix damage immediately. Replace worn or broken parts. Remove any buildup of grease, oil, or debris.

On self-propelled equipment, disconnect battery ground cable (-) before making adjustments on electrical systems or welding on machine.

On towed implements, disconnect wiring harnesses from tractor before servicing electrical system components or welding on machine.

Avoid Hot Exhaust

Servicing machine or attachments with engine running can result in serious personal injury. Avoid exposure and skin contact with hot exhaust gases and components.

Exhaust parts and streams become very hot during operation. Exhaust gases and components reach temperatures hot enough to burn people, ignite, or melt common materials.

Clean Exhaust Filter Safely

During exhaust filter cleaning operations, the engine may run at elevated idle and hot temperatures for an extended period of time. Exhaust gases and exhaust filter components reach temperatures hot enough to burn people, or ignite or melt common materials.

Keep machine away from people, animals, or structures which may be susceptible to harm or damage from hot exhaust gases or components. Avoid potential fire or explosion hazards from flammable materials and vapors near the exhaust. Keep exhaust outlet away from people and anything that can melt, burn, or explode.

Closely monitor machine and surrounding area for smoldering debris during and after exhaust filter cleaning.

Adding fuel while an engine is running can create a fire or explosion hazard. Always stop engine before refueling machine and clean up any spilled fuel.

Always make sure that engine is stopped while hauling machine on a truck or trailer.

Contact with exhaust components while still hot can result in serious personal injury.

Avoid contact with these components until cooled to safe temperatures.

If service procedure requires engine to be running:

• Only engage power-driven parts required by service procedure

• Ensure that other people are clear of operator station and machine

Keep hands, feet, and clothing away from power-driven parts.

Always disable movement (neutral), set the parking brake or mechanism and disconnect power to attachments or tools before leaving the operator’s station.

Shut off engine and remove key (if equipped) before leaving the machine unattended.

Work in a Ventilated Area

Engine Exhaust fumes can cause sickness or death. If it is necessary to run an engine is an enclosed area, remove the exhaust fumes from the area with an exhaust pipe extension.

If you do not have an exhaust pipe extension, open the doors and get outside air into the area.

Support Machine Properly

Always lower the attachment or implement to the ground before you work on the machine. If the work requires that the machine or attachment be lifted, provide secure support for them. If left in a raised position, hydraulically supported devices can settle or leak down.

Do not support the machine on cinder blocks, hollow tiles, or props that may crumble under continuous load. Do not work under a machine that is supported solely by a jack. Follow recommended procedures in this manual.

When implements or attachments are used with a machine, always follow safety precautions listed in the implement or attachment operator's manual.

Prevent Machine Runaway

Avoid possible injury or death from machinery runaway.

Do not start engine by shorting across starter terminals. Machine will start in gear if normal circuitry is bypassed.

Never start engine while standing on ground. Start engine only from operator’s seat, with transmission in neutral or park.

Park Machine Safely

Before working on the machine:

• Lower all equipment to the ground.

• Stop the engine and remove the key.

• Disconnect the battery ground strap.

• Hang a “DO NOT OPERATE” tag in operation station.

Transport Tractor Safely

A disabled tractor is best transported on a flatbed carrier. Use chains to secure the tractor to the carrier. The axles and tractor frame are suitable attachment points.

Before transporting the tractor on a low-loader truck or flatbed rail wagon, make sure that the hood is secured over the tractor engine and that doors, roof hatch (if equipped) and windows are properly closed.

Never tow a tractor at a speed greater than 10 km/h (6 mph). An operator must steer and brake the tractor under tow.

Servicing Cooling System Safely

Explosive release of fluids from pressurized cooling system can cause serious burns.

Shut off engine. Only remove filler cap when cool enough to touch with bare hands. Slowly loosen cap to first stop to relieve pressure before removing completely.

Service Accumulator Systems Safely

Escaping fluid or gas from systems with pressurized accumulators that are used in air conditioning, hydraulic, and air brake systems can cause serious injury. Extreme heat can cause the accumulator to burst, and pressurized lines can be accidentally cut. Do not weld or use a torch near a pressurized accumulator or pressurized line.

Relieve pressure from the pressurized system before removing accumulator.

Relieve pressure from the hydraulic system before removing accumulator. Never attempt to relieve hydraulic system or accumulator pressure by loosening a fitting.

Accumulators cannot be repaired.

Service Tires Safety

Explosive separation of a tire and rim parts can cause serious injury or death:

• Do not attempt to mount a tire without the proper equipment and experience to perform the job.

• Always maintain the correct tire pressure. Do not inflate the tires above the recommended pressure. Never weld or heat a wheel and tire assembly. The heat can cause an increase in air pressure resulting in a tire explosion. Welding can structurally weaken or deform the wheel.

• When inflating tires, use a clip-on chuck and extension hose long enough to allow you to stand to one side and NOT in front of or over the tire assembly. Use a safety cage if available.

• Check tires for low pressure, cuts, bubbles, damaged rims or missing lug bolts and nuts.

Service Front-Wheel Drive Tractor Safely

When servicing front-wheel drive tractor with the rear wheels supported off the ground and rotating wheels by engine power, always support front wheels in a similar manner. Loss of electrical power or transmission hydraulic system pressure will engage the front driving wheels, pulling the rear wheels off the support if front wheels are not raised. Under these conditions, front drive wheels can engage even with switch in disengaged position.

Tightening Wheel Retaining Bolts / Nuts

Torque wheel retaining bolts/nuts at the intervals specified in section Break-In Period and Service.

Avoid High Pressure Fluids

Inspect hydraulic hoses periodically - at least once per year - for leakage, kinking, cuts, cracks, abrasion, blisters, corrosion, exposed wire braid or any other signs of wear of damage.

Replace worn or damaged hose assemblies immediately with John Deere approved replacement parts.

Escaping fluid under pressure can penetrate the skin causing serious injury.

Avoid the hazard by relieving pressure before disconnecting hydraulic or other lines. Tighten all connections before applying pressure.

Search for leaks with a piece of cardboard. Protect hands and body from high-pressure fluids.

If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury should reference a knowledgeable medical source. Such information is available in English from Deere & Company Medical Department in Moline, Illinois, U.S.A., by calling 1-800-822-8262 or +1-309-748-5636.

Do Not Open High-Pressure Fuel System

High-pressure fluid remaining in fuel lines can cause serious injury. Do not disconnect or attempt repair of fuel lines, sensors, or any other components between the high-pressure fuel pump and nozzles on engines with High Pressure Common Rail (HPCR) fuel system.

Only technicians familiar with this type of system can perform repairs. (See your John Deere dealer.)

Store Attachments Safely

Stored attachments can fall and cause serious injury or death.

Securely store attachments and implements to prevent falling. Keep playing children and bystanders away from storage area.

Dispose of Waste Properly

Improperly disposing of waste can threaten the environment and ecology. Potentially harmful waste used with John Deere equipment include such items as oil, fuel, coolant, brake fluid, filters, and batteries.

Use leakproof containers when draining fluids.

Do not use food or beverage containers that may mislead someone into drinking from them. Do not pour waste onto the ground, down a drain, or into any water source.

Air conditioning refrigerants escaping into the air can damage the Earth’s atmosphere. Government regulations may require a certified air conditioning service center to recover and recycle used air conditioning refrigerants.

Inquire on the proper way to recycle or dispose of waste from your local environmental or recycling center, or from your John Deere dealer.