Service Steering & Brakes

Front Axle Oil

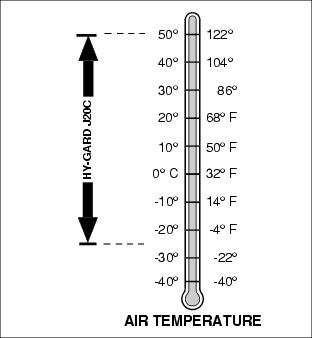

Use oil viscosity based on the expected air temperature range during the period between oil changes.

The following John Deere transmission and hydraulic oil is preferred:

IMPORTANT: Avoid damage! Only use a quality oil in this front axle gear case. DO NOT mix any other oils in this gear case. DO NOT use BIO-HY-GARDŽ in this gear case. |

Checking the Front Axle Oil Level (4WD Models)

1. Park vehicle safely. (See Park Safely in the Operating section.)

IMPORTANT: Avoid damage! Help prevent contaminants from entering the oil dipstick location. Clean area around dipstick before removing. |

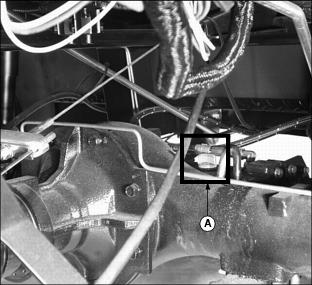

2. Unscrew dipstick (A) and remove it from axle.

3. Wipe dipstick dry with a clean cloth.

NOTE: DO NOT tighten dipstick. Allow threads to rest on top of the axle housing.

4. Install dipstick into the axle housing.

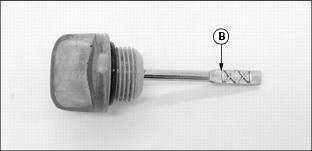

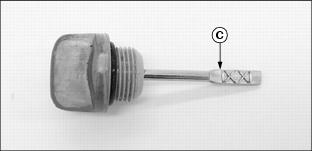

5. Remove dipstick. Oil level should be at level (B) on the dipstick.

ˇ If oil is low, add oil. Oil level should be to the top of the XX area (B) on the dipstick.

6. Install and tighten dipstick.

Changing the Front Axle Oil

(4WD Models)

1. Park vehicle safely. (See Park Safely in the Operating section.)

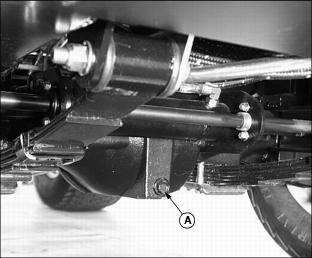

2. Place container under the oil drain location.

3. Remove differential drain plug (A) to drain oil.

4. Install and tighten drain plug.

IMPORTANT: Avoid damage! Help prevent contaminants from entering the oil dipstick location. Clean area around dipstick before removing. |

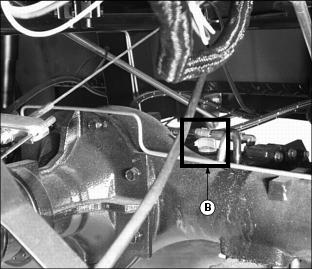

5. Unscrew dipstick (B) and remove it from the differential housing.

6. Add approximately 3.3 L (3.5 qt) of oil through the dipstick opening.

7. Wipe dipstick dry with a clean cloth.

NOTE: DO NOT tighten dipstick. Allow threads to rest on top of the dipstick opening.

9. Remove dipstick. Oil level should be at level (C) on the dipstick.

ˇ If oil is low, add oil. Oil level should be to the top of the XX area (B) on the dipstick.

10. Install and tighten dipstick.

NOTE: Oil will flow very slowly through the front axle housing. Check oil level again after the first several hours of operation.

Brake Fluid

The following John Deere heavy duty brake fluid is PREFERRED for all drum and disc brakes:

Other brake fluids may be used if the above John Deere brake fluid is not available and they provide the following:

ˇ Conforms to Motor Vehicle Safety Standard No. 116.

ˇ Minimum wet boiling point 140° C (284° F).

ˇ Minimum dry boiling point 232° C (450° F) to prevent vapor lock.

Check Brake Fluid Level

1. Park vehicle safely. (See Park Safely in the Operating section.)

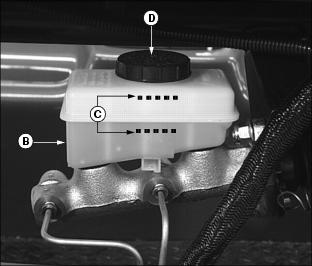

3. Visually check the see-through reservoir (B) for the appropriate amount of fluid.

ˇ Fluid levels must be maintained between the "MAX" maximum and "MIN" minimum fill lines (C).

ˇ If the fluid level is above the "MIN" minimum fill line, DO NOT open the cap.

ˇ Carefully clean area around reservoir cap (D). Unscrew cap.