Assembly

Identify Parts

Parts in Crate

Bag of Parts

NOTE: All hardware used to attach parts to shipping container may be discarded. They are not required for assembly.

Preparing the Vehicle

Required Equipment

• Loader cannot be mounted on the X465 Garden Tractor.

IMPORTANT: Avoid damage! Installation of correct transaxle hydrostatic pressure relief valve to machine is necessary before loader operation begins. Failure to do so will result in damage to machine. |

• All models require transaxle hydrostatic pressure relief valve and a free-wheeling valve control lever. See your authorized dealer for the correct valve. Lever is furnished with loader.

• Models X475 and X575 require hydraulic coupler kit. See your authorized dealer.

• All models require 4-ply rated front tires. These are standard on all machines.

NOTE: Operating loader without hydraulic cylinder shut-off valve in closed position will result in poor loader response. The shut-off valve comes with the front hitch kit and may already be installed.

• For best loader performance, all models should have hydraulic cylinder shut-off valve installed. See your authorized dealer.

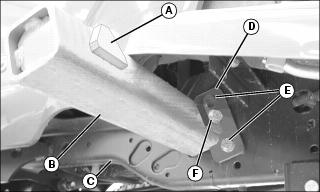

Install Rear Mount Tube

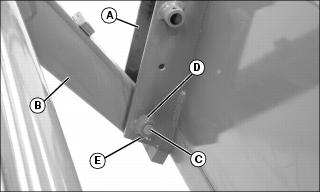

NOTE: Triangular tabs (A) on rear mount tube must face rearward with long end facing downward.

1. Insert rear mount tube (B) into square holes in machine frame (C).

2. Fasten mount ears (D) to each side of machine frame using four M12 x 40 mm hex bolts (E) and M12 locknuts. Do not tighten.

3. Fasten rear mount tube to mount ears using two M12 x 90 mm hex bolts (F) and M12 locknuts. Do not tighten.

4. Tighten all fasteners to 130 N•m (96 lb-ft).

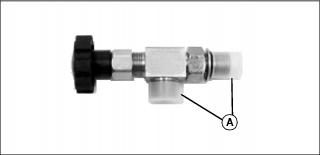

Install Hydraulic Shut-Off Valve

NOTE: For ease of installation, remove mower deck.

1. Remove plastic caps (A) from threaded ends of hydraulic shut-off valve.

NOTE: Place a container under the control valve to catch fluid that may drain out during this procedure.

2. Move hydraulic levers to relieve pressure.

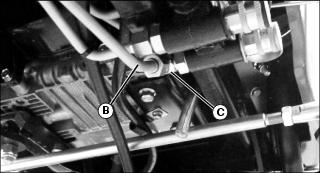

Picture Note: Right side, under footrest.

3. Remove hydraulic line (B) from 90° elbow (C) by loosening nut.

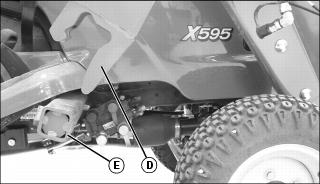

Picture Note: View is from under machine at right footrest. Top of picture is front of machine.

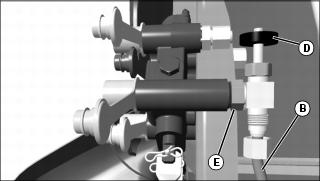

5. Fasten hydraulic shut-off valve (D) to control valve. Do not tighten nut (E).

6. Fasten hydraulic line (B) to hydraulic shut-off valve and tighten nut.

Install Free-Wheeling Control Lever and Transaxle Hydrostatic Pressure Relief Valve

1. Park machine safely. (See Parking Safely in the SAFETY section.)

IMPORTANT: Avoid damage! Existing forward free-wheeling valve on machine must be replaced by transaxle hydrostatic pressure relief valve. This valve protects transaxle from unnecessary stress. |

2. Slide seat fully rearward and remove front bolts from seat assembly.

3. Slide seat fully forward and remove rear bolts from seat assembly.

4. Disconnect wiring harness from underside of seat and remove seat assembly.

5. Four-Wheel Drive Machines: Remove cap from shift knob and remove retaining bolt (A) to remove shift knob.

Picture Note: Tire removed for clarity.

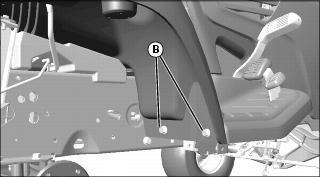

6. Remove two bolts (B) on each side of fender deck, in front of rear wheels.

8. Disconnect wiring harness from underside of fender deck and remove fender deck.

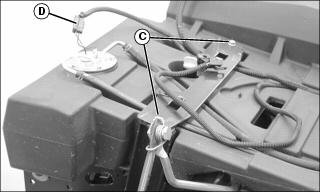

10. Remove two bolts (C) from fuel tank hold-down bracket.

11. Disconnect wiring harness (D) from fuel pump and remove fuel tank.

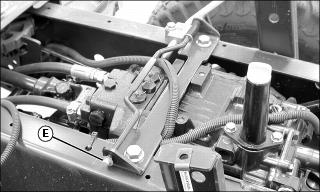

12. Remove and discard cap nut (E) from free-wheeling valve control lever.

NOTE: Retain plastic cap for new free-wheeling valve control lever.

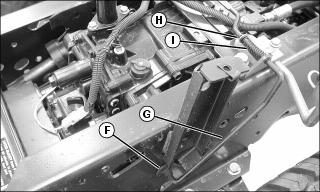

13. Remove and retain plastic cap (F) from other end of free-wheeling valve control lever.

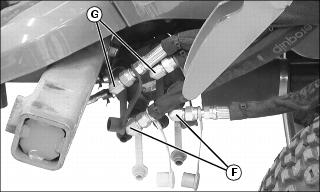

14. Remove and discard existing free-wheeling valve control lever (G) from machine.

NOTE: Retain washer and spring for new free-wheeling valve control lever.

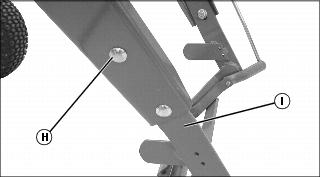

15. Remove and retain washer (H) and spring (I) from free-wheeling valve control lever.

IMPORTANT: Avoid damage! Clean transaxle before removing valve. Contamination of hydraulic system may cause damage. |

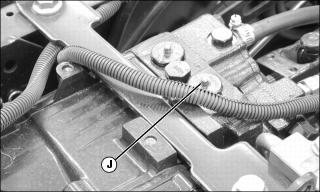

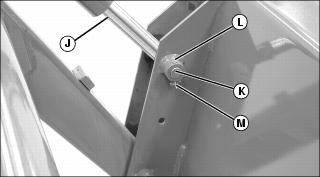

16. Remove existing free-wheeling valve (J) from right-hand location.

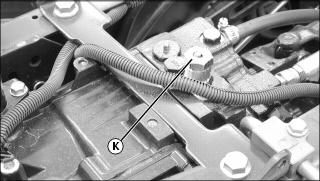

17. Install new transaxle hydrostatic pressure relief valve (K).

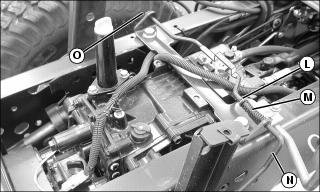

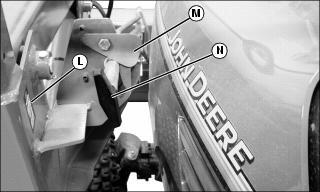

18. Place original washer (L), then spring (M) on new free-wheeling valve control lever (N).

19. Install new free-wheeling valve control lever on machine.

20. Install cap nut (O) on one end of lever.

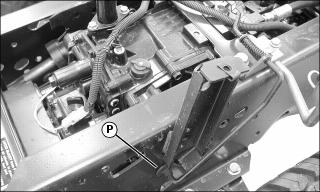

21. Install plastic cap (P) on other end of lever.

Assemble and Attach Bucket and Loader

1. Put bucket on a hard, level surface.

2. Cut bands holding loader to pallet.

IMPORTANT: Avoid damage! Use care when lowering lift arms into bucket bracket. Grease fittings may be damaged if struck. |

3. Tip loader forward on pallet. Align lower bucket holes and boom holes with drift pin.

NOTE: Make sure drilled pin and cotter pin are to inside of bucket.

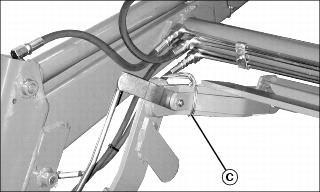

4. Fasten bucket (A) to lift arms (B) using two lock pins (C), drilled pins (D) and cotter pins (E).

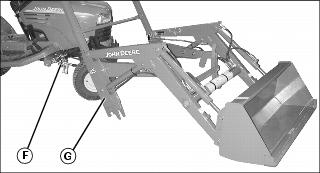

NOTE: Machine must be close enough to connect loader hydraulic hoses to machine hydraulic quick couplers (F).

6. Start engine and drive machine between loader masts (G) at an angle.

7. Stop engine and lock park brake.

8. Relieve hydraulic pressure by moving machine upper and lower hydraulic control levers back and forth several times.

9. Remove dust plugs from hydraulic couplers on machine and dust caps from loader hoses.

NOTE: Make sure to route hoses to inside of loader masts and lift frame.

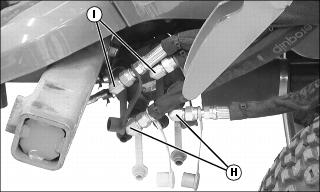

10. Install two lower hydraulic hose couplers (H) (yellow and silver) to hydraulic couplers on machine by matching color coded dust plugs and caps.

11. Install two upper hydraulic hose couplers (I) (black and green) to hydraulic couplers on machine by matching color coded dust plugs and caps.

13. Use upper hydraulic control lever to extend two bucket cylinders 12.7 cm (5 in.).

15. Attach bucket to cylinders (J) with two locking pins (K), drilled pins (L) and cotter pins (M).

Align Loader

2. Use upper hydraulic control lever to roll bucket forward until it is level on the ground.

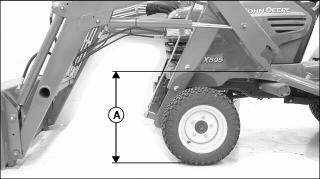

3. Use lower hydraulic control lever to raise loader masts 46-56 cm (18-22 in.) (A) to clear rear mount tube on machine.

5. Relieve pressure from hydraulic hoses by moving hydraulic control levers back and forth several times.

6. Disconnect four loader hoses and position hoses over cross bar.

7. Cut wire (C) from latch lever.

8. Start engine and unlock park brake.

9. Drive machine slowly forward between loader masts (D) to align masts with brackets (E) on both sides.

10. Stop engine and lock park brake.

11. Relieve pressure from hydraulic hoses by moving hydraulic control levers back and forth several times.

NOTE: Make sure to route hoses to inside of loader masts and lift frame.

12. Install two lower hydraulic hose couplers (F) (yellow and silver) to hydraulic couplers on machine by matching color coded dust plugs and caps.

13. Install two upper hydraulic hose couplers (G) (black and green) to hydraulic couplers on machine by matching color coded dust plugs and caps.

14. Plug four loose dust plugs and caps into each other so they are out of the way.

15. Loosen, but do not remove, four 5/8 x 1-1/2 in. carriage bolts (H) on both sides of front yoke (I).

16. Loosen, but do not remove, four 3/8 x 1 in. hex bolts (J) attaching crossbar (K) to loader.

NOTE: Refer to decal (L) on loader.

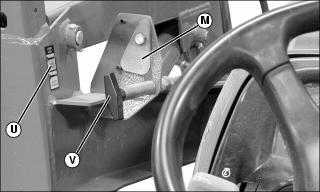

17. Rotate latch keeper (M) up. Grasp handle (N) on latch rod and pull up and out of slot. Push forward to unlatch (remove) position.

18. Start engine and unlock park brake.

NOTE: When mounting loader masts onto rear mount tube, machine may need to be positioned to obtain correct alignment.

Lower loader masts slowly to prevent loader masts from hitting machine footrests.

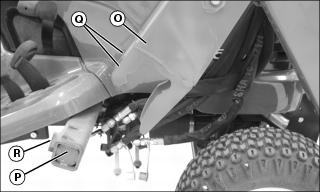

19. Push lower hydraulic control lever forward to lower loader masts (O) onto rear mount tube (P). Make sure to center mast hooks (Q) over stop blocks (R) on both sides of rear mount tube. Check to ensure that both mast hooks have dropped completely down onto rear mount tube.

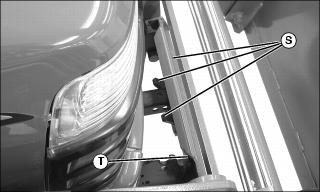

20. Slowly retract boom cylinders until front yoke (S) has fully captured machine front bumper (T).

NOTE: Front wheels must be off ground.

21. Push upper hydraulic control lever forward to roll bucket until front wheels clear ground.

NOTE: Before latching, make sure front yoke plate (S) has fully captured machine front bumper (T). Also check that upright mast hooks (Q) have completely captured rear mount tube (P) on both sides.

22. Grasp latch rod handle (V) and pull latch rod back and down into slot to latch (use) position.

23. Latch keeper (M) must rotate to down position.

24. Latch rod must rest on bottom of slot. If not, adjust latch rod.

25. Make sure that front yoke (S) has fully captured machine front bumper (T).

26. Curl bucket back to lower front wheels to ground.

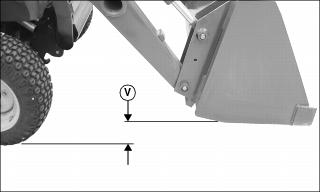

27. Pull lower hydraulic control lever back slowly to raise bucket 15-30 cm (6-12 in.) (V). This will help align loader front yoke and upright masts to machine front bumper and rear mount tube. Four 5/8 in. carriage bolts should be in center of front yoke slots.

28. Slowly lower loader lift arms and bucket down to ground.

29. Stop engine and lock park brake.

NOTE: Open machine hood for better access to four 5/8 in. carriage bolts.

30. Tighten four 5/8 in. carriage bolts (two on each side of front yoke) so connection between front yoke and upright masts will not slip when removing loader from machine.

31. With loader still on machine, tighten four 3/8 x 1 in. hex bolts connecting crossbar to loader upright masts to 54 N•m (40 lb-ft).

NOTE: If connection held by four 5/8 in. carriage bolts slips during loader removal, adjustment process must be repeated.

32. Remove loader from machine.

33. Tighten four 5/8 x 1-1/2 in. carriage bolts to 244 N•m (180 lb-ft).

34. Attach loader to machine. If loader does not attach easily and securely, adjustment process must be repeated.

35. Cycle all loader cylinders completely several times after completing installation process. This will ensure that all hydraulic lines and cylinders are filled with hydraulic fluid.