Service

Service Intervals

Each Use

Beginning of Season

End of Season

Grease

The following greases are preferred:

• John Deere Multi-Purpose SD Polyurea Grease

• John Deere Multi-Purpose HD Lithium Complex Grease

• John Deere Moly High Temperature EP Grease

If not using any of the preferred greases, be sure to use a general all-purpose grease with an NLGI grade No.2 rating.

Wet or high speed conditions may require use of a special-use grease. Contact your Servicing dealer for information.

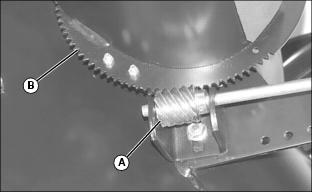

Lubricating Worm Gear and Chute

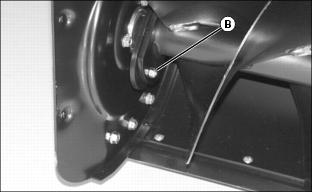

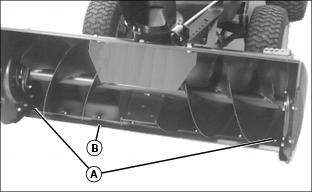

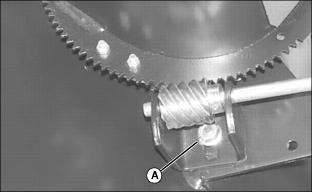

Apply recommended grease on worm gear (A), and between chute (B) and chute base.

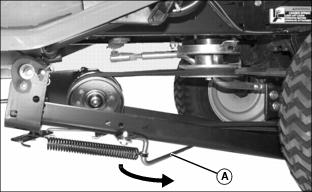

Adjusting Drive Belt Tension

1. Pivot tightening lever (A) forward and lock under snowthrower frame to tighten belt.

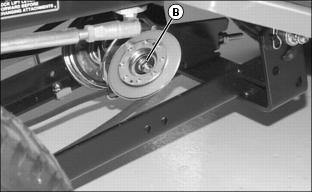

2. Loosen nut (B) on left idler.

• Belt tension is correct when idler arm (D) is parallel with welded frame (E) as shown.

6. Tighten nut (B) on left idler, loosened earlier.

Replacing Shear Bolt

IMPORTANT: Avoid damage! Replacement shear bolts must be same as original shear bolts on attachment: |

4. Find and correct the cause for shearing.

5. Remove spare shear bolt (A) from bracket.

6. Install new shear bolt (B) in rotor.

Reversing or Replacing Scraper Blade

Reverse scraper blade when edge is rough or worn. Replace blade if it is bent.

2. Reverse or replace blade (B).

3. Fasten scraper blade with bolts.

Adjusting Worm Gear

2. Move worm gear against teeth on discharge chute.

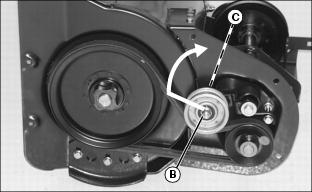

Replacing Auger Drive Belt

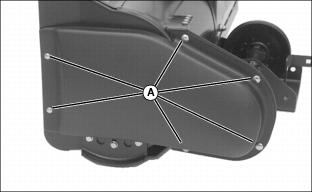

1. Remove six bolts (A) and remove belt cover.

NOTE: If necessary, idler arm can be held up by placing punch in hole (C) behind idler on support plate.

2. Place wrench on idler bolt (B) and turn clockwise.

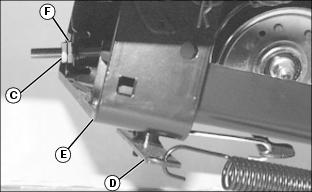

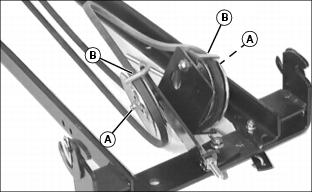

Replacing Drive Belt

1. Remove snowthrower from machine.

2. Loosen nuts (A) on idlers to loosen guides (B).

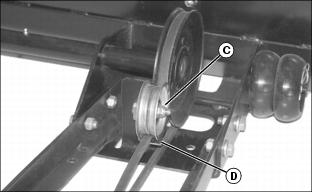

4. Loosen bolt (C) and pivot belt guide (D) away from belt.

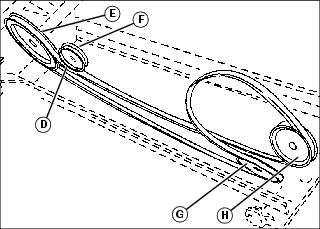

• Put belt around sheave (E) with belt under idler (F).

• Put belt guide (D) close to belt and tighten guide bolt.

NOTE: Support for idlers (G) and (H) needs to be parallel with center line of machine.

V-shaped side of belt goes in groove of idler (G). Flat side of belt goes in groove of idler (H).

• Put belt around idlers (G) and (H) and tighten belt guide bolts.