Assembly

Prepare Vehicle For Assembly

1. Remove top and sides of shipping crate.

2. Remove seats and packaged parts from vehicle.

3. Remove tires from cargo box and sides of vehicle.

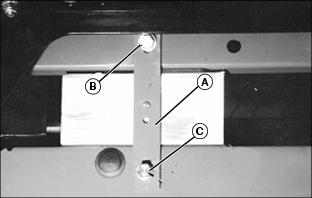

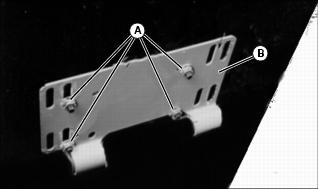

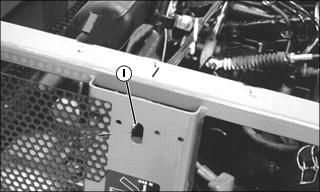

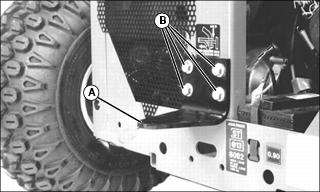

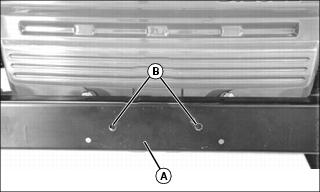

4. Locate two shipping brackets (A) on each side of vehicle frame.

5. Remove self-tapping screws (B) at each side. Retain these four screws to install the load guard later.

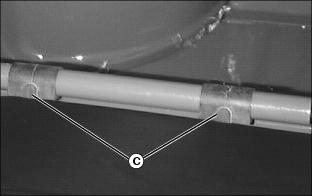

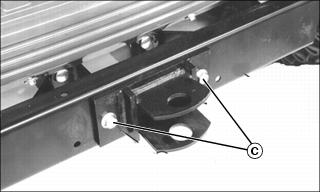

6. Lift cargo box off vehicle frame.

7. Remove self-tapping screws (C) and shipping brackets (A). Discard the shipping brackets.

8. Install two self-tapping screws (C) back into holes they were removed from on right side of machine. Install one of these screws into rear hole on left side of machine. Discard the last screw.

9. Remove and discard the shipping hardware securing the vehicle to pallet at foot platform and rear frame.

Remove Battery

· 4x2 - Access under passenger seat.

· 6x4 - Access through opening at rear of vehicle.

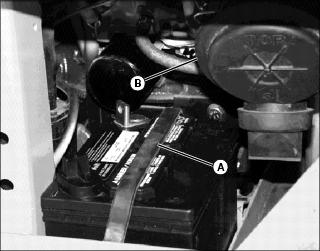

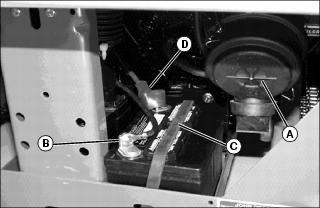

Picture Note: GATOR 6x4 shown.

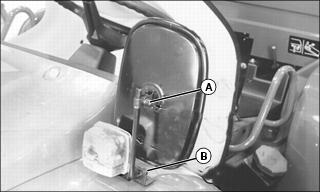

2. Disconnect rubber hold-down strap (A).

3. Release latches on air cleaner canister cover (B). Remove cover to provide clearance for battery removal.

4. Remove battery from vehicle. Remove and discard the protective cap from the negative (-) terminal.

5. Install air cleaner cover with rubber dust unloading valve pointing downward. Check instruction molded into canister cover for proper installation.

Prepare Battery for Installation

Prepare "Maintenance-Free" Battery

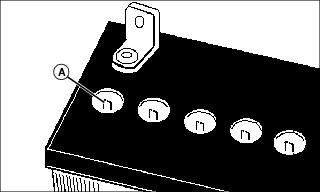

NOTE: Use this setup procedure for batteries marked "Maintenance-Free."

1. Remove threaded cell caps from battery.

2. Slowly add electrolyte to each cell until level reaches bottom of split ring (A) in each vent well.

3. Wait 5 - 10 minutes after filling. Add additional electrolyte if necessary to attain proper level.

4. Install and tighten cell caps.

5. Charge battery for 10 to 15 minutes at 25 - 30 amps or 30 minutes at 4 - 6 amps.

Prepare "Maintenance Type" Battery

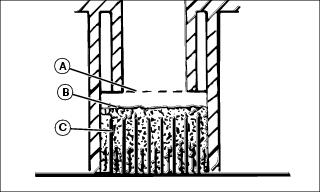

NOTE: Use this setup procedure for batteries with single manifold cap and vent hose.

1. Remove and discard the tape and plugs from battery cells.

IMPORTANT: Avoid damage! Do not fill cells to the bottom of filler neck (A). Electrolyte can overflow when battery is charged and cause damage. |

2. Slowly add electrolyte (B) until plates (C) are just covered.

3. Charge battery at 15 amps for 10 minutes or 7 amps for 30 minutes. Do not exceed recommended charging rate. If electrolyte starts to boil over, decrease charging rate.

4. After charging, add electrolyte until level is halfway between top of plates and bottom of filler neck.

5. Install rubber vent hose to fitting on manifold. Install manifold to battery so vent hose is at positive (+) end of battery.

Reduce Tire Pressure

2. Check all tires with an accurate gauge. Reduce pressure to 34 - 41 kPa (5 - 6 psi).

Install Wheels

Install Rear Wheels

1. Measure circumference of rear tires. Select the wheels with largest tire circumference for the most rearward position to provide the best ground contact for drive wheels.

2. Install plastic cap on each rear axle hub.

3. Raise rear of vehicle with a safe lifting device. Place support stands under vehicle.

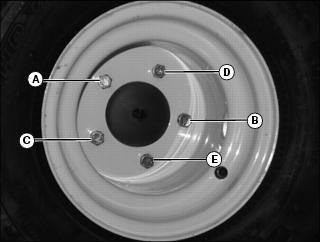

4. Attach each rear wheel to axle hub with valve stem to outside using five wheel bolts. Tighten wheel bolts evenly in proper sequence (A), (B), (C), (D), and (E) until snug. Finish tightening to 90 N·m (65 lb-ft) using a torque wrench.

5. Remove support stands and lower vehicle.

Install Front Wheels

1. Raise front of vehicle with a safe lifting device. Place support stands under vehicle.

2. Slide front wheels onto front axle hubs.

3. Secure front wheels with M16x40 flanged cap screws. Tighten cap screws to 90 N·m (65 lb-ft) using torque wrench.

4. Remove safety stands and lower vehicle to the ground.

Install Spark Arrestor (4x2)

NOTE: Spark arrestor is factory-installed on 6x4 utility vehicles.

1. Align hole in spark arrestor (A) with pre-drilled hole in muffler pipe.

2. Slide screen end of arrestor into muffler pipe.

3. Install and tighten tap screw (B) to secure.

Install Steering Wheel

1. Remove and discard plastic protective cap from steering shaft.

2. Install steering wheel onto steering shaft. Turn steering wheel to position front wheels straight and facing forward.

4. Apply multi-purpose grease to steering shaft.

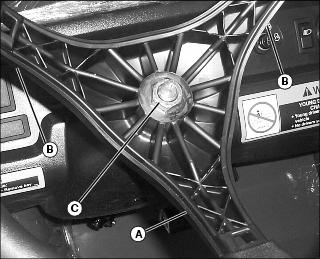

5. Install steering wheel onto steering shaft with one spindle (A) positioned at 180° at bottom of wheel and spindles (B) at approximately 45° at top of wheel.

6. Position front wheels straight and facing forward.

7. Install steering wheel onto steering shaft.

8. Install and tighten nut (C) to 38 N·m (28 lb-ft).

9. Install cover (D) so the John Deere name is positioned properly.

Install Seats

NOTE: This procedure applies to both seats on non-homologated vehicles and to the passenger seat on homologated units.

1. Remove screws (A) from bottom of seat base bracket on each seat.

NOTE: Apply silicone lubricant to inner surface of seat bushings to improve ease of seat rotation if desired.

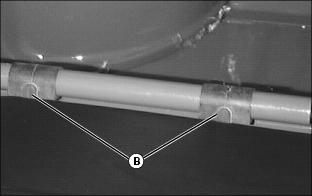

2. Install rubber seat bushings (B) onto support rail so tabs face toward rear of vehicle.

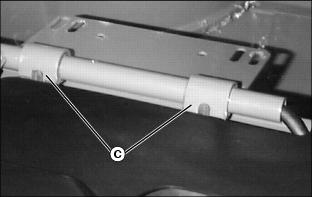

3. Position seat base bracket onto support rail so hinges (C) fit around rubber bushing tabs.

NOTE: Seat hardware must be installed in correct slots in bracket. Always use set of slots closest to center of vehicle when installing seat.

4. Rotate seat bracket upward. Install original hardware in slots closest to center of vehicle to secure seat. Do not tighten completely.

5. Slide seat forward or rearward to desired position.

6. Tighten seat screws to 10 N·m (7 lb-ft).

Install Operator Seat (Homologated 4x2 Units Only)

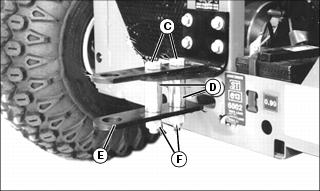

1. Remove nuts (A) and seat base bracket (B) from seat plate.

2. Position rubber seat bushings (C) on support rail so tabs face toward rear of vehicle.

3. Position seat bracket (B) onto support rail so hinges (D) fit around rubber bushing tabs.

NOTE: If a seat height adjustment is desired, see the OPERATING section of this manual for the adjustment procedure before proceeding.

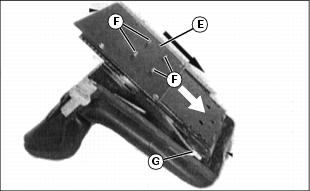

4. Turn seat over. Position plate (E) so mounting studs (F) are closest to front of seat.

5. Pull out seat adjusting lever (G). Slide rails of plate (E) into rear of seat rails. Continue sliding the plate assembly as far forward as possible to install.

6. Tighten the capscrews to 28 N·m (20 lb-ft).

7. Rotate seat base bracket upward. Align studs in seat plate with holes in bracket. Secure with nuts (A). Tighten nuts completely.

Install Operator Seat (Homologated 6x4 Units Only)

NOTE: If necessary, see the operator seat adjustment procedure in the OPERATING section for further information about possible seat positions.

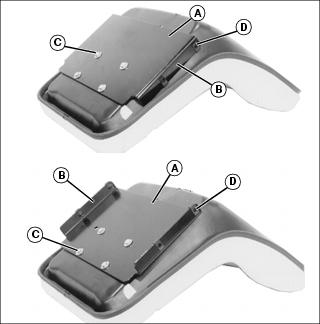

Picture Note: Top photo - legs (B) shown in up position. Bottom photo - legs shown in down position.

1. Position inner seat bracket (A) onto seat so legs (B) face up (for low or low-mid position) or down (for high-mid or high position).

2. Install screws (C) to secure inner seat bracket to seat. Tighten completely.

3. Install four clip-on nuts (D) to each seat bracket with threaded ends toward center of seat bracket.

4. Place seat onto outer seat bracket (E) of vehicle.

5. Align holes in inner seat bracket with set of holes in outer seat bracket for desired height and forward/rearward position.

6. Install cap screws (F) to secure seat to outer seat bracket on both sides. Tighten completely.

Install Battery

Picture Note: GATOR 6x4 shown.

1. Remove air cleaner canister cover (A) to provide clearance for battery installation.

2. Install battery into vehicle with negative (-) terminal (B) positioned toward rear of vehicle.

3. Install air cleaner canister cover with rubber dust unloading valve pointing downward. Check instruction molded into canister cover for proper installation.

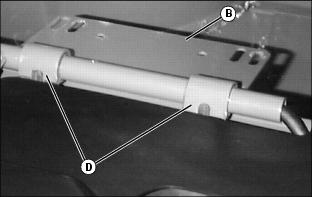

4. Secure battery hold-down strap (C).

5. Install red positive battery cable (D) to positive (+) terminal first using M6x16 cap screw, flat washer, and nut. Tighten the connection.

6. Install black negative battery cable to negative (-) terminal last using M6x16 cap screw, flat washer, and nut. Tighten the connection.

7. Apply petroleum jelly on battery terminals to help prevent corrosion.

8. Slide protective cover down the battery positive cable and seat it over the positive (+) terminal.

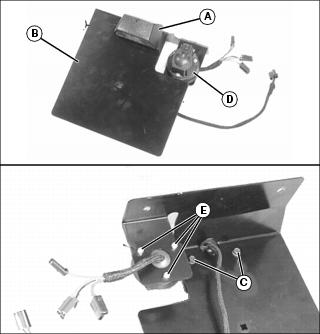

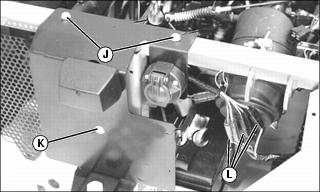

Install License Plate Holder (Homologated Units Only)

1. Position license plate light (A) on holder (B) with lens facing down. Secure light to holder with two self-tapping screws (C).

2. Position trailer receptacle (D) onto holder with the cover hinge at top side of holder. Secure receptacle to holder with three M5x30 mm screws and nuts (E).

3. Mark centerpoint (F) of rear frame using a pencil.

4. Place holder onto rear frame. Align hole (G) in holder with mark on rear frame.

5. Push holder forward keeping the front edge parallel with front edge of rear frame.

6. Mark drill holes (H) on rear frame. Remove holder.

7. Center punch and drill two 6.6 mm (17/64 in.) holes at location (H).

8. Route the light and trailer receptacle harnesses through slot (I) and position holder onto rear frame.

9. Align mounting holes and install two self-tapping screws (J) to secure holder to vehicle.

10. Insert spacer between vehicle frame and license plate holder at location (K). Install M8x50 mm carriage bolt through holder and spacer. Secure with flanged nut.

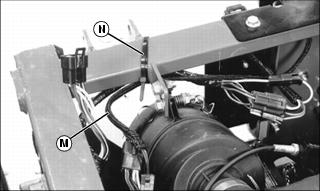

11. Connect trailer receptacle connectors (L) to main wiring harness.

12. Route license plate light harness (M) under rear frame and connect to main wiring harness.

13. Fasten the light harness to frame with tie strap (N) at same location as main harness tie strap.

14. Check for proper operation of license plate light and trailer receptacle.

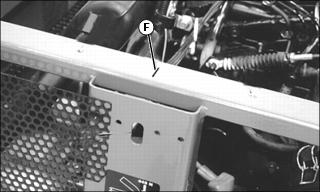

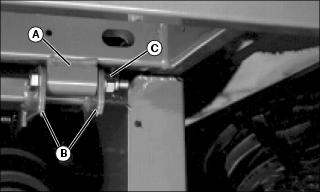

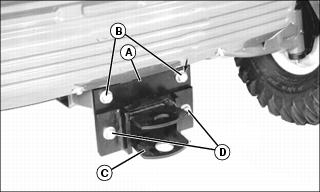

Install Cargo Box

1. Position cargo box onto vehicle frame so hinges (A) are positioned inside pivot brackets (B).

2. Secure cargo box using M12x90 cap screws and flanged lock nuts (C). Install cap screw with threads to the outside of vehicle.

3. Tighten cap screws until pivot brackets contact ends of hinge.

4. Apply a spray lubricant to the pivot hardware, hinges, and pivot brackets.

NOTE: The 90° bent end of support rod is already installed in cargo box frame.

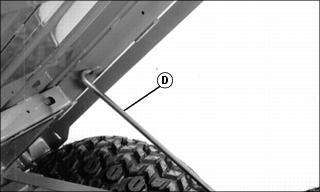

5. Raise and hold cargo box securely. Cut tie strap to release cargo box support rod (D).

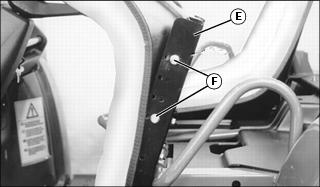

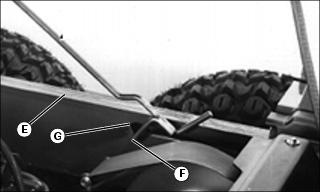

6. Push inward on support rod forcing it over sill (E).

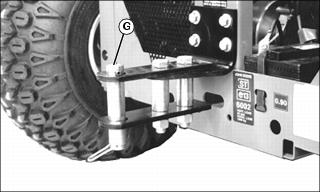

7. Route end (F) of support rod into slot (G).

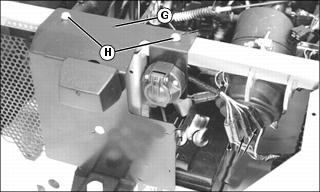

Install Load Guard

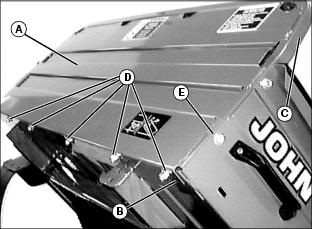

1. Install load guard (A) to cargo box so bottom lip (B) is positioned on underside of box and square tube frame (C) is to the inside of box.

2. Secure bottom of load guard with M8x20 carriage bolts, flat washers, and flanged lock nuts (D). Tighten nuts to 25 N·m (18 lb-ft).

3. Attach both sides of load guard using self-tapping screws (E) retained from shipping brackets on cargo box.

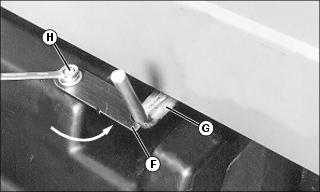

5. Engage cargo box lock if equipped (manual lift only):

a. Push lock (F) tight against cargo box latch (G).

Installation of Bedliner

If optional bedliner will be installed, do not install liner until all safety decals are applied as described later in this section. See the installation instructions provided with bedliner for assembly procedures.

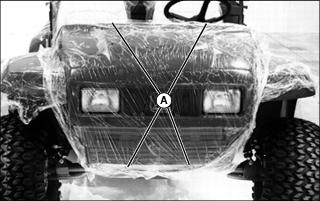

Remove Shipping Wrap

1. Remove screws (A) and lift hood up and off vehicle.

2. Remove plastic shipping wrap from hood.

3. Use a sharp utility knife to carefully cut the plastic wrap where fenders join metal frame.

4. Pull plastic wrap up and away from fender and remove remaining plastic in joint by pulling from below.

5. Remove the plastic wrap from rear fenders and box extensions.

IMPORTANT: Avoid damage! Vibration of hood against headlight housing may cause early failure of headlight lamps. Allow clearance around headlight housings when installing hood. |

6. Install hood and tighten top screws first.

7. Push hood upward leaving space around headlight housings. Tighten bottom screws.

Install Side Mirror (Homologated Units Only)

NOTE: Side mirror can be mounted on either side of vehicle as desired. To mount mirror on right side, mirror bracket and reinforcement plate (under left fender) must be removed and attached to right fender.

1. Obtain the side mirror provided.

2. Remove plastic cap (A) to expose nut. Loosen the nut.

3. Install side mirror onto support rod.

4. Slide mirror up or down to desired position. Tighten nut.

5. Loosen nut (B) and adjust mirror to desired right or left position. Tighten nut.

Install Rear Hitch (Homologated Units Only)

1. Install hitch bracket (A) to rear frame using four M12x35 mm capscrews (B) and M12 locknuts. Tighten nuts to 130 N·m (96 lb-ft).

2. Install two 3/4x4-3/4 in. capscrews (C), spacers (D), and plate (E) to bracket. Secure with two 3/4 in. lockwashers and nuts (F). Tighten nuts to 375 N·m (280 lb-ft).

3. Install and secure hitch pin (G) through hitch bracket and lower plate.

Install Front Hitch (Homologated Units Only)

Vehicles With Bumper

1. Use the front hitch as a template and center it right-to-left and top-to-bottom on front bumper (A).

2. Mark, center punch, and drill two 13 mm (1/2 in.) holes (B) through bumper.

3. Install front hitch to bumper using two capscrews and locknuts (C). Tighten locknuts completely.

Vehicles Without Bumper

NOTE: Use holes located closest to edge of adapter plate for attachment to the vehicle.

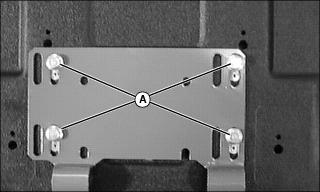

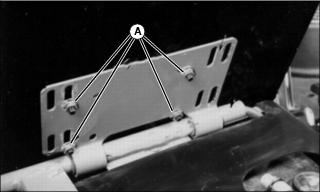

1. Install adapter plate (A) to vehicle with capscrews and locknuts (B). Tighten locknuts completely.

2. Install front hitch (C) to adapter plate with two capscrews and locknuts (D). Tighten locknuts completely.

Install Safety Decals

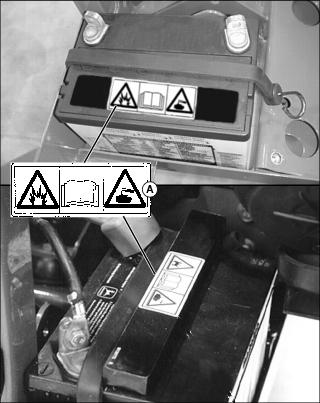

1. Apply safety decal (A) to battery:

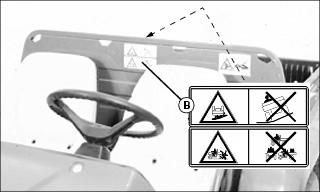

2. Apply safety decal (B) over each existing decal centered on front and rear of load guard. If installing optional bedliner, apply the third decal over the existing decal on bedliner.

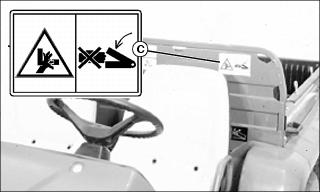

3. Apply safety decal (C) over existing decal on left front side of load guard.

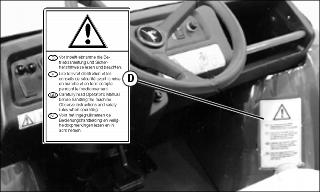

4. Apply the appropriate multi-language safety decal (D) over existing decal on right front fender.

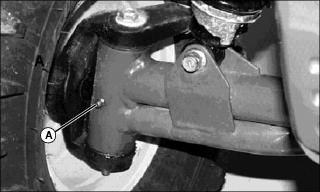

Lubricate Front King Pins

NOTE: Refer to Service Lubrication section of operator's manual for recommended lubricants.

1. Lubricate grease fitting (A) on each king pin bushing with one or two shots of recommended grease.

2. Wipe off excess grease from fitting.

Add Operating Fluids

IMPORTANT: Avoid damage! Vehicle is shipped without fluids. Add and check all fluids before starting engine. See the appropriate SERVICE sections in this manual for complete instructions. |

1. Add engine oil to proper level.

2. Add transaxle oil to proper level.

NOTE: Cooling system is filled at the factory but overflow reservoir must be brought to proper level.

3. Prepare engine coolant. Add coolant to overflow reservoir so 25 - 50 mm (1 - 2 in.) of coolant appears in reservoir.

Clean and Polish Plastic Hood and Fenders

1. Remove any dust or dirt with water.

2. Dry thoroughly to avoid water spots.

3. Spray PLEDGE®1 onto plastic surfaces and leave on for 30 to 60 seconds.