Operating

Daily Operating Checklist

o Check coolant level (GATOR 6x4).

o Clean operator's station and engine compartment.

o Clean engine cooling screens (GATOR 4x2).

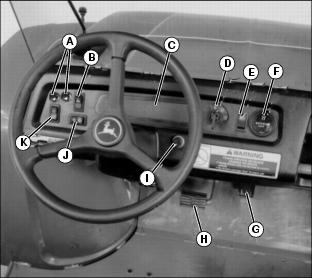

Operator Controls

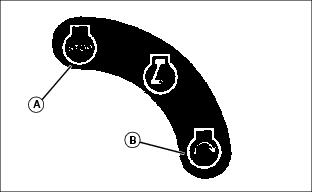

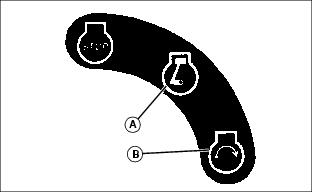

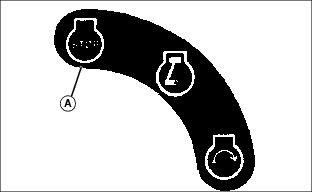

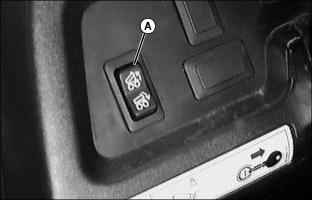

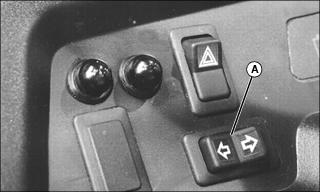

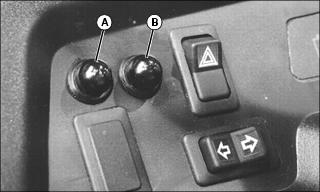

A - Flashing Bulb Integrity Indicators (Optional)

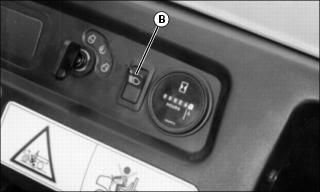

B - Warning Light Switch (Optional)

J - Turn Signal Switch and Indicator (Optional)

K - Cargo Box Power Lift Switch (Optional)

Miscellaneous Controls

Indicator Panel (4x2)

Indicator Panel (6x4)

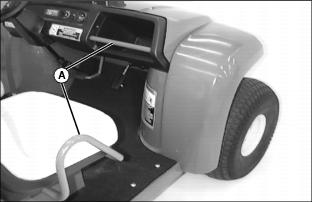

Using Hand Holds

Hand holds (A) are provided for passenger balance when driving over rough terrain. Use dash bar and side rails on seats for stability.

Adjusting Seats

NOTE: This procedure applies to both seats on non-homologated vehicles and only to the passenger seat on homologated units.

Picture Note: Operator seat shown.

3. Slide seat forward or rearward to desired position.

4. Tighten seat bracket hardware to 10 N·m (7 lb-ft).

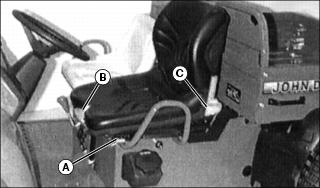

Adjusting Operator Seat (Homologated 4x2 Only)

Adjusting Forward/Rearward Position

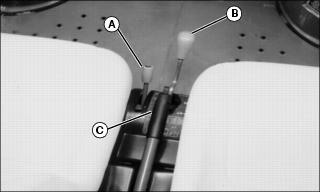

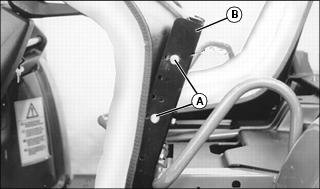

1. Push and hold lever (A) to the left.

2. Slide seat forward or rearward to desired position.

Adjusting Seat Comfort

Pull lever (B) up and slide rearward on seat to adjust for your desired comfort.

Adjusting Seat Suspension

1. Move lever (C) down to adjust suspension for operator weight as indicated on lever.

2. Push lever all the way down to reset.

Adjusting Seat Height

3. Lift seat off seat base bracket (B).

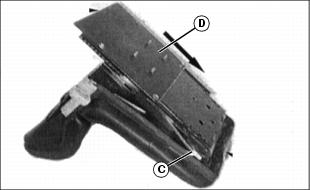

4. Turn seat over. Pull out seat adjusting lever (C) and slide plate (D) toward seat back to remove.

5. Using wrench provided, remove seat rails from plate. Attach rails to plate for desired height position but do not tighten the hardware completely:

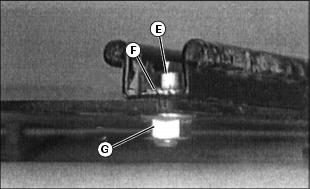

· LOW Position - Secure rails to bracket with four capscrews (E), lock washers (F), and nuts (G).

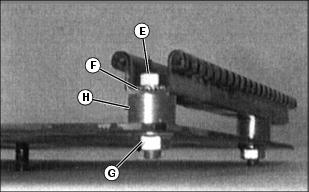

· MEDIUM Position - Secure rails to bracket with four capscrews (E), lock washers (F), small spacers (H), and nuts (G).

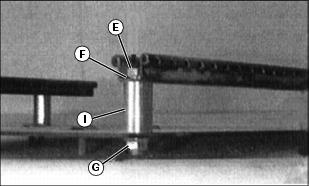

· HIGH Position - Secure rails to bracket with four capscrews (E), lock washers (F), large spacers (I), and nuts (G).

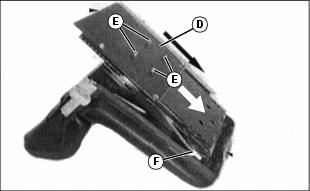

6. Turn seat over. Position plate (D) so mounting studs (E) are closest to front of seat.

7. Pull out seat adjusting lever (F). Slide rails of plate (D) into rear of seat rails. Continue sliding the plate assembly as far forward as possible to install.

8. Tighten the capscrews to 28 N·m (20 lb-ft).

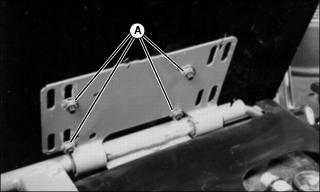

9. Rotate seat base bracket upward. Align studs in seat plate with holes in bracket. Secure with nuts (A). Tighten nuts completely.

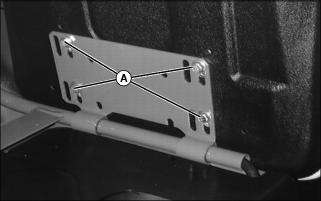

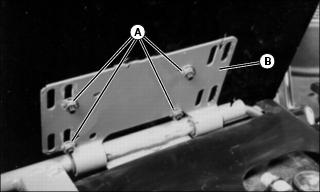

Adjusting Operator Seat (Homologated 6x4 Only)

1. Remove cap screws (A) at both sides of seat.

2. Remove seat from outer seat bracket (B) on vehicle.

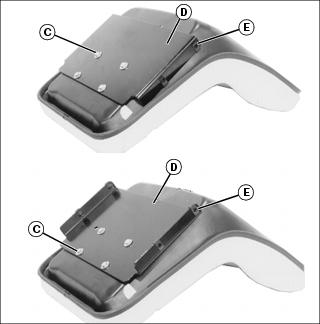

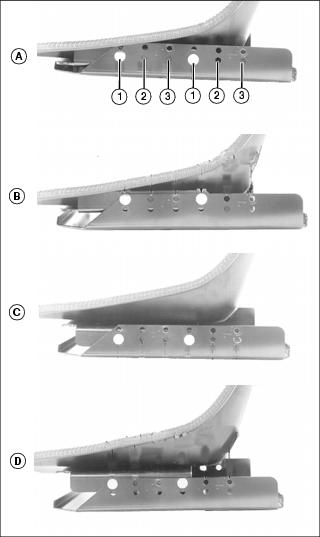

Picture Note: Top photo - legs (E) shown in up position. Bottom photo - legs shown in down position.

4. Remove inner seat bracket (D) from seat.

5. Position inner seat bracket onto seat so legs (E) face up (for low or low-mid position) or down (for high-mid or high position).

6. Install screws (C) to secure inner seat bracket to seat. Tighten completely.

7. Place seat onto outer seat bracket of vehicle.

NOTE: Horizontal spacing between holes in outer seat bracket determines forward/rearward seat position (1 - forward, 2 - middle, 3 rear position). Vertical spacing between the holes determines seat height. Seat must be secured to bracket with all four cap screws.

W02343, W02344, W02345, W02346,

8. Align holes in inner seat bracket with set of holes in outer seat bracket for desired height and forward/rearward position.

9. Install original cap screws to secure seat to outer seat bracket on both sides. Tighten completely.

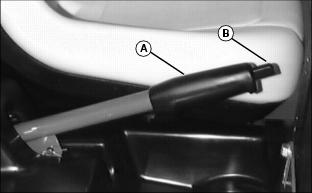

Using Park Brake

NOTE: Pushing down on brake pedal while locking and unlocking park brake decreases effort required to apply park brake lever.

Locking the Park Brake

2. Pull up on lever (A) and latch into position.

Unlocking the Park Brake

4. Release lever down completely.

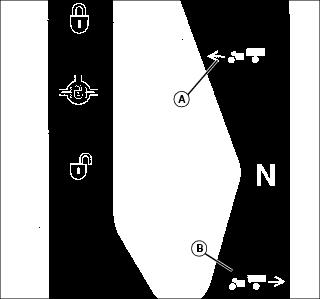

Operating Differential Lock

Differential lock (A) provides better traction when rear wheels start to slip. Engaging the differential lock will cause all rear wheels to turn together at equal speed.

Engaging the Differential Lock

IMPORTANT: Avoid damage! Transaxle may be damaged if differential lock is engaged incorrectly. Reduce speed before engaging or disengaging differential lock. |

1. Stop or reduce engine speed to 1\3 throttle or less.

2. Push differential lock lever forward to locked position (A):

· Differential lock will remain engaged as long as lever is forward.

· Panel indicator light will come on.

Disengaging the Differential Lock

NOTE: Panel light only indicates when lever is in ON or OFF position. To ensure true disengagement of differential lock, you must equalize torque on both axles.

1. Stop or reduce engine speed to 1\3 throttle or less.

2. Drive the vehicle straight ahead at a constant speed.

3. Pull lever rearward to unlocked position (B). Panel indicator light will go off.

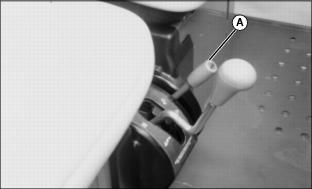

Using Transaxle Shift Lever

2. Allow engine to come to a low idle speed.

· Forward (A) - Push shift lever forward.

· Reverse (B) - Push shift lever to right, then pull rearward.

Testing Safety Systems

The safety systems installed on your machine should be checked before each machine use. Be sure you have read the machine operator manual and are completely familiar with the operation of the machine before performing these safety system checks.

Use the following checkout procedure to check for normal operation of machine.

If there is a malfunction during one of these procedures, Do not operate machine. See your John Deere dealer for service.

Perform these tests in a clear open area. Keep bystanders away.

Testing the Safety Start System

1. Sit on the operator's seat.

2. Place key switch in STOP position (A).

4. Move transaxle shift lever to forward position.

5. Move key switch to start position (B). Engine should not crank. Turn key switch off.

6. Move transaxle shift lever to reverse position.

7. Move key switch to start position. Engine should not crank. Turn key switch off.

Starting the Engine

1. Sit on operator seat. Do not start engine at this time.

2. Push down on accelerator pedal to check for free movement of pedal assembly. Release pedal.

NOTE: The vehicle has a neutral start safety switch. The engine will not start unless the transaxle shift lever is in N (Neutral) position.

3. Move gear shift lever to N (Neutral) position.

5. Turn key switch to the run position (A).

6. Check that the battery discharge and oil pressure indicator lights are on (GATOR 6x4).

7. Pull out on choke if engine is cold.

8. Turn key to start position (B).

· Coolant temperature indicator light should come, then go off after a few seconds.

IMPORTANT: Avoid damage! Starter may be damaged if starter is operated for more than 20 seconds at a time: · Wait two minutes before trying again if engine does not start. |

9. Release key to the run position when engine starts.

· If engine does not start within five seconds, turn key to STOP and wait ten seconds before trying to start again.

· In very cold conditions, attempt starting engine three times only, then wait 5 minutes before trying again. This will allow time for starter to cool and prevent damage to starter.

IMPORTANT: Avoid damage! Do not operate the engine at full throttle or under load until engine has warmed up, or engine damage could occur. |

11. Run engine at half speed for 2 or 3 minutes to warm the engine.

Stopping Engine

Always lock the park brake and remove the key before leaving the machine unattended. |

IMPORTANT: Avoid damage! If engine has been running hard and is hot, do not stop engine immediately. Remove load from engine. Run engine at 1/3 to 1/2 throttle for several minutes to cool engine. |

2. Move gear shift lever to N (Neutral) position.

4. Turn key switch to STOP position (A).

Operating the Vehicle

1. Move transaxle shift lever to forward or reverse gear position as desired.

2. Look in the direction the vehicle will travel.

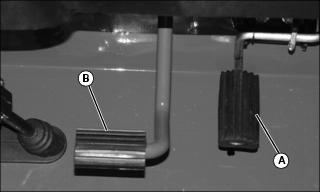

3. Push down accelerator pedal (A) slowly and smoothly to begin vehicle travel.

4. Release accelerator and apply brake pedal (B) evenly and firmly to slow down or stop.

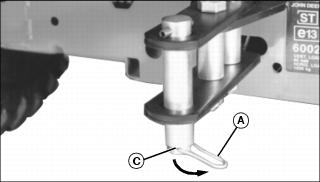

Using the Cargo Box Lock

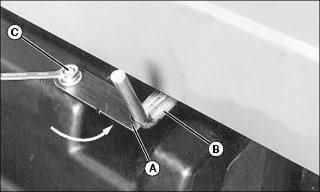

Engage Lock

1. Push lock (A) tight against cargo box latch (B).

Disengage Lock

2. Rotate lock (B) 180° away from cargo box latch (C).

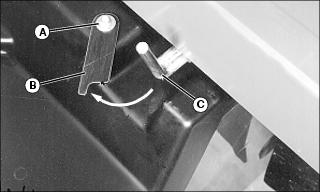

Raising and Lowering Cargo Box

NOTE: The manual lift and lower procedures should only be done after cargo box is emptied.

Manual Lift

1. Park the vehicle safely. (See Parking Safely in the SAFETY section.)

3. Release latch (A) by pushing inward. Raise cargo box manually with lift handle on side of cargo box.

4. Place support rod (B) into slot (C) when cargo box is fully raised.

5. To lower cargo box, raise cargo box slightly using lift handle.

6. Release support rod from latch slot by pulling up on lower end of rod.

NOTE: Support rod will latch at front of cargo box when box is lowered completely.

7. Slowly lower cargo box. Support rod will slide along slotted channel.

Power Lift (Optional)

1. Park the vehicle safely. (See Parking Safely in the SAFETY section.)

3. Raise cargo box by pressing and holding top of rocker switch (A). Release switch when box is at desired dump height or when maximum height is reached.

NOTE: Allowing the Power Lift actuator clutch to slip briefly (click or ratchet) after cargo box is fully lowered will help keep cargo box secure and reduce rattling caused by travel vibrations.

4. Lower cargo box by pressing and holding bottom of rocker switch until box is lowered completely.

NOTE: Hourmeter will run whenever key is in RUN position. Turn key to STOP position after using the Power LIft option.

Dumping a Load

1. Back up vehicle to dump site.

2. Park the vehicle safely. (See Parking Safely in the SAFETY section.)

IMPORTANT: Avoid damage! Stop dumping immediately if actuator clutch slippage occurs. Lower cargo box completely and remove excess load by hand before dumping. |

4. Raise cargo box to dump load.

5. Lower cargo box when empty.

6. Latch tailgate closed. Do not drive vehicle with cargo box in raised position.

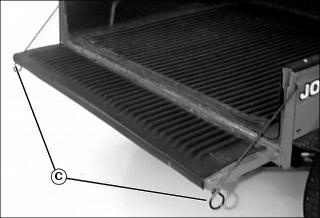

Operating the Tailgate

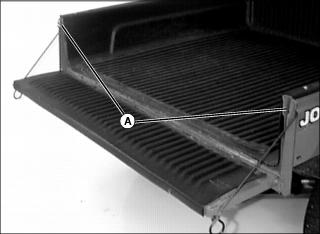

1. Push in and down on loop (A) of tailgate latch rods to unhook rods from slot (B) in tailgate.

2. Pull latch rods out and down.

3. Lower tailgate until it rests on ends of latch rods (C).

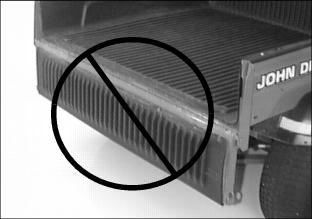

IMPORTANT: Avoid damage! Do not drive vehicle with tailgate hanging down unsupported. Lugs on tires will contact tailgate causing structural damage. |

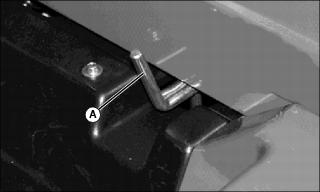

Removing Tailgate

NOTE: Latch rods on early model vehicles are not equipped with rubber hose sleeves.

1. Remove and retain rubber hose sleeves from latch rod ends (A).

2. Raise tailgate slightly and rotate latch rods to disengage from slots in cargo box sides.

3. Remove latch rods from sides of tailgate. Install rubber hose sleeves to rod ends for storage.

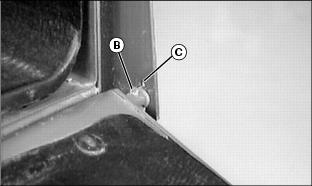

4. Tilt tailgate downward and align tab (B) on tailgate rod end with slot (C) in cargo box bracket.

5. Slide tailgate sideways so tab passes through slot (C) to the outside of the cargo box bracket.

6. With one side of tailgate now detached, slide tailgate in opposite direction to complete removal.

7. To install, reverse the steps.

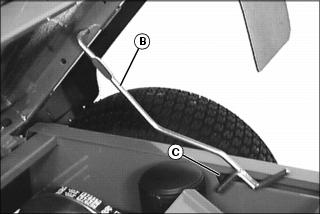

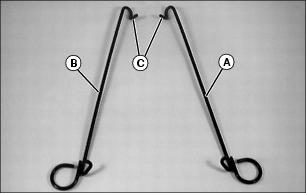

Installing Tailgate Latch Rods

1. Identify right (A) and left (B) latch rods.

NOTE: Latch rods on early model vehicles are not equipped with rubber hose sleeves.

2. Remove and retain rubber hose sleeves (C) from latch rod ends.

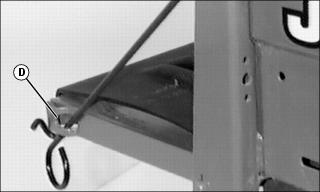

3. Route latch rod through tailgate opening (D) as shown.

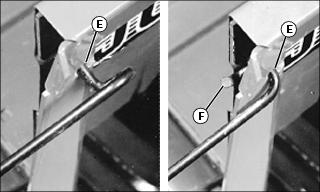

4. Raise tailgate slightly from horizontal position. Insert end of latch rod through slot (E) in cargo box bracket. Rotate rod around the bracket to secure.

5. Install rubber hose sleeve onto rod end (F), if equipped.

6. Raise tailgate and push inward and upward on latch rod to engage rod in slot (G) in top rail.

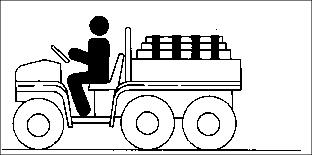

Loading the Cargo Box

On level terrain, maximum cargo box payload capacity is:

· GATOR 4x2 - 227 kg (500 lb).

· GATOR 6x4 - 363 kg (800 lb).

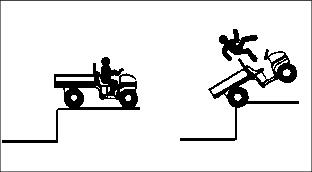

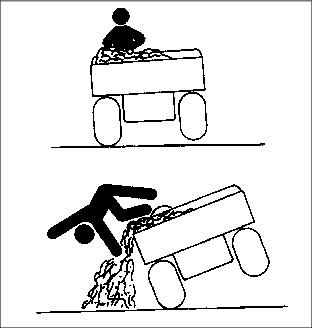

Reduce load and ground speed when operating over rough or hilly terrain. DO NOT overload vehicle. Limit loads to those that can be safely controlled.

When loading objects into vehicle, be sure load is securely anchored and evenly distributed in cargo box. Shifting loads will affect stability.

Avoid concentrated loads at rear or side of cargo box to prevent vehicle from tipping over. Be sure load is evenly distributed.

Because there is a big difference in weight between dry and wet sand, the only way of getting true weight of the load you are carrying is by using a weigh scale.

For example, dry sand weighing 227 kg (500 lb) would be approximately 1/2 of cargo box volume for the GATOR 4x2.

For other materials such as those that are bagged, weight is normally printed on the bag.

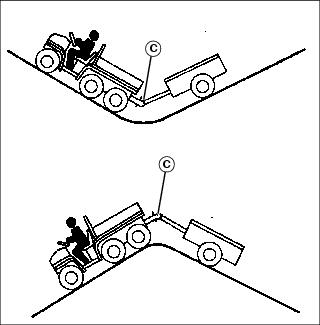

Towing Loads

· Do not tow a load unless the cargo box is loaded.

· Do not tow a load that exceeds the following:

· GATOR 4x2 - 409 kg (900 lb).

· GATOR 6x4 - 544 kg (1200 lb).

· Do not exceed a tongue weight of 45 kg (100 lb).

· Never exceed 16 km/h (10 mph) when towing a load. Tow load at a speed slow enough to maintain control.

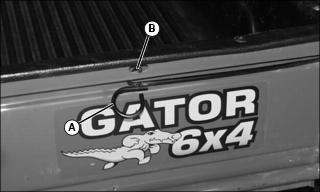

· Non-road Homologated Units Only: Decal (A) at rear of vehicle indicates maximum force values for approved John Deere hitch on non-homologated utility vehicles only. Maximum horizontal force on hitch is 2508 N (564 lb). Maximum vertical force on hitch is 445 N (100 lb).

· Homologated Units Only: Decal (B) at rear of vehicle indicates the horizontal and vertical capacities for approved John Deere road homologated clevis hitch.

· Always use approved hitch and hitch point provided for the utility vehicle. DO NOT modify the hitch or hitch point in any way.

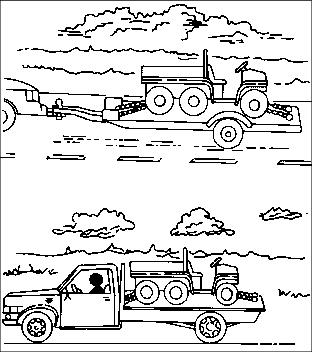

Transporting Vehicle

IMPORTANT: Avoid damage! Never tow the vehicle. Transaxle damage will occur if vehicle is towed. Haul the vehicle on a heavy-duty trailer or on a full-size truck. |

NOTE: Space limitations may vary from one truck manufacturer to another. Short bed trucks do not have the necessary length requirement to accommodate the vehicle.

1. Drive utility vehicle onto the trailer or truck.

2. Leave transaxle shift lever in forward or reverse gear.

3. Park vehicle safely (See Parking Safely in the SAFETY section.)

4. Fasten vehicle to trailer or truck with straps, chains, or cables.

5. Equip the trailer or truck with all the necessary lights and signs required by local, state, provincial, or federal laws.

Using Front and Rear Hitches (Homologated Units Only)

1. Push down latch (A) to the vertical position.

3. Align hole in attachment with holes in vehicle hitch.

4. Install hitch pin to connect attachment to vehicle.

NOTE: Hole (C) in hitch pin is offset. This requires latch (A) be rotated upward on side of hitch pin closest to hole. If rotated to opposite side of hitch pin, latch will be difficult to open.

5. Rotate latch (A) to the horizontal position on side of pin closest to hole (C).

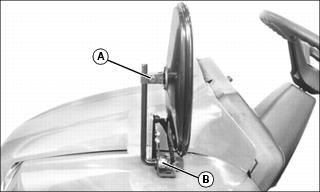

Adjusting Mirror (Homologated Units Only)

1. Adjust mirror height position

c. Adjust mirror to desired height. Tighten nut.

2. Adjust mirror left/right position:

b. Move mirror to desired left/right position. Tighten nut.

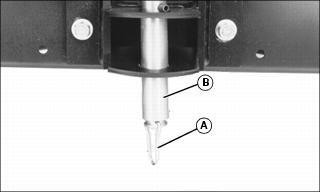

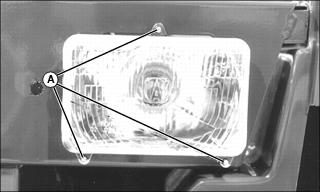

Adjusting Headlights (Homologated Units Only)

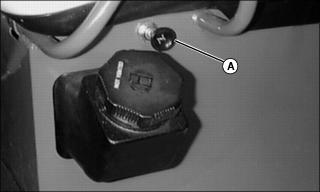

2. Tighten or loosen screws (A) at rear of headlight until beam is in the desired position.

IMPORTANT: Avoid damage! Vibration of hood against headlight housing may cause headlight lamps to fail early. Allow clearance around headlight housings when installing hood. |

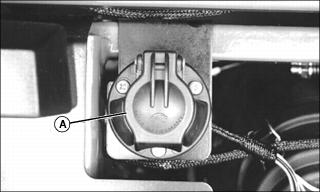

Using Rear Electrical Outlet (Homologated Units Only)

A 7-pin electrical outlet (A) is located at rear of vehicle. Use this outlet to power trailer and implement lights, turn signals, and other remote electrical equipment. A mating plug is available from your John Deere dealer.

A - Blue - Left Hand Turn Signal

D - Green - Right Hand Turn Signal

E - Black - Right Rear and Left Front Lights

G - Red - Left Rear and Right Front Lights

Operating the Lights (Homologated Units Only)

Directional Lights

Directional light switch (A) controls the right and left directional lights.

· Left signal light ON - Press left arrow on light switch.

· Right signal light ON - Press right arrow on light switch.

· Signal lights OFF - Move switch to the center position.

Headlights, Park Lights, and License Plate Light

Headlight switch (B) controls the headlights, park and license plate lights.

· Park and license plate lights ON - Push top of switch to first position.

· Headlights ON - Push top of switch all the way in.

· All lights OFF - Push bottom of switch all the way in.

Flasher Lights

Flasher (hazard) light switch (C) controls the front and rear flasher lights on the utility vehicle and also the attachment if using the rear-mounted 7-pin electrical outlet.

· Flashers ON - Push top of switch.

· Flashers OFF - Push bottom of switch.

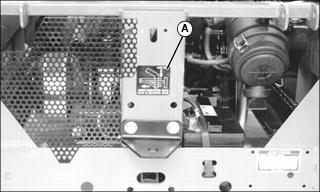

Using Bulb Integrity Lamps

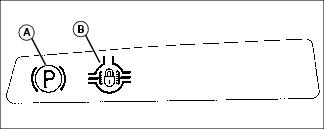

Bulb integrity lamps (A) and (B) are indicator lights for the vehicle and any attachment equipped with lights if using the 7-pin electrical outlet at rear of vehicle.

· Bulb integrity lamp (A) will flash when at least two turn signal or warning flasher bulbs are lit and indicates no problems with lamps, bulbs, or wiring. This lamp should always flash when turn signals or warning flashers are used, even when a trailer with lamps is attached. If this lamp does not flash, check for burned out bulbs on vehicle.

· Bulb integrity lamp (B) will flash when at least three turn signal or warning flasher bulbs are lit and should always flash when turn signals or warning flashers are used with a trailer connected to the 7-pin electrical outlet at rear of vehicle. If this lamp does not flash, check for burned out bulbs on vehicle and attachment.

Using the Horn

Ignition key must be in the ON position to operate the horn.