Service Transmission

Transaxle Oil

IMPORTANT: Avoid damage! Use recommended oil only. Do not use engine oil or "Type F" automatic transmission fluid. |

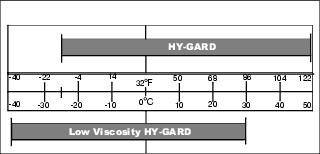

Use oil viscosity based on the expected air temperature range during the period between oil changes.

John Deere HY-GARD transmission and hydraulic oil is recommended. John Deere Low Viscosity HY-GARD transmission and hydraulic oil may be used, if within the specified temperature range.

Other oils may be used if they meet John Deere standards JDM J20C and JDM J20D.

Checking Transaxle Oil Level

IMPORTANT: Avoid damage! Hot hydraulic oil will expand and show incorrect oil level. Check oil level: |

1. Park the machine safely. (See Parking Safely in the SAFETY section.)

2. Raise and secure cargo box.

IMPORTANT: Avoid damage! Dirt and debris in oil may cause damage to the transaxle. Clean area around opening before removing dipstick. |

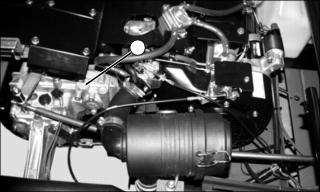

3. Remove dipstick (A) located on the top of the transaxle housing. Wipe dipstick clean.

4. Check oil level by inserting dipstick fully into transaxle case without screwing it in, then removing and checking oil level.

5. Add oil as needed through the dipstick fill hole.

6. Install and tighten dipstick.

Changing Transaxle Oil

IMPORTANT: Avoid damage! If brakes start to chatter or are noisy when applied, change transaxle oil before waiting until the service interval. |

1. Park the machine safely. (See Parking Safely in the SAFETY section.)

2. Raise and secure cargo box.

3. Place a drain pan under the transaxle.

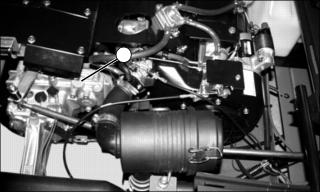

4. Access drain plug (A) through slot on underside of machine. Remove plug and drain oil.

5. Check O-ring on drain plug. Replace if missing or in poor condition.

6. Install and tighten drain plug. Tighten to 20 N·m (177 lb-in.).

IMPORTANT: Avoid damage! Dirt and debris in oil may cause damage to the transaxle. Clean area around opening before removing dipstick. |

7. Remove dipstick (B) located on top of transaxle housing. Wipe dipstick clean.

8. Add approximately 2.8 L (3 qt) of oil.

9. Check oil level by inserting dipstick fully into transaxle case without screwing it in, then removing to check level.

10. Wait for two minutes then check oil level. Add oil if necessary.

Checking Drive Belt

1. Park the machine safely. (See Parking Safely in the SAFETY section.)

3. Raise and secure cargo box.

4. Remove engine access panel.

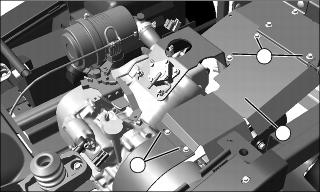

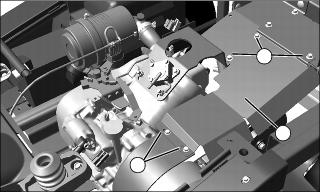

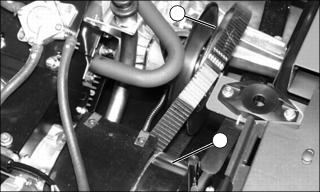

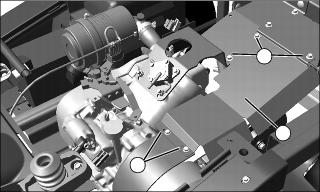

5. Remove the five cap screws (A) and belt guard (B).

6. Rotate and inspect belt for wear or damage.

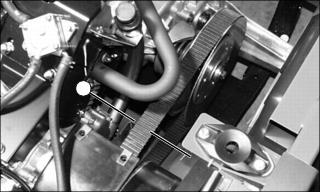

7. Measure the top surface of the belt width at (C). Dimension should be a minimum of 27 mm (1.1 in.).

8. Replace belt if worn beyond limit.

9. Install engine access panel.

10. Install belt guard and tighten cap screws to 14 N·m (124 lb-in.).

12. Tip seats back and secure passenger seat retention strap.

Replacing Drive Belt

1. Park the machine safely. (See Parking Safely in the SAFETY section.)

3. Raise and secure cargo box.

4. Remove engine access panel.

5. Remove the five cap screws (A) and belt guard (B).

6. Route the belt over pulley (C) of the driven clutch. Rotating the driven pulley will aid in removing the belt.

7. Route belt over drive pulley (D) to remove.

8. Install new belt by routing over drive pulley and then over the driven clutch pulley.

9. Install belt guard and tighten cap screws to 14 N·m (124 lb-in.).

10. Install engine access panel.

12. Tip seats back and secure passenger seat retention strap.

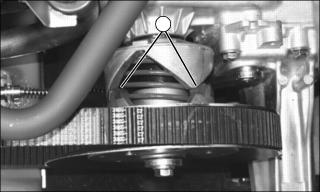

Checking Secondary Clutch Buttons

1. Park the machine safely. (See Parking Safely in the SAFETY section.)

3. Raise and secure cargo box.

4. Remove engine access panel.

5. Remove the five cap screws (A) and belt guard (B).

6. Check for missing or worn clutch buttons (C).

· There should not be any excessive wear, or metal-to-metal contact.

· If replacement is necessary, see your John Deere dealer.

7. Install belt guard and tighten cap screws to 14 N·m (124 lb-in.).

8. Install engine access panel.

10. Tip seats back and secure passenger seat retention strap.