Service Lubrication

Grease

The following greases are preferred:

• John Deere Multi-Purpose SD Polyurea Grease

• John Deere Multi-Purpose HD Lithium Complex Grease

• John Deere Moly High Temperature EP Grease

If not using any of the preferred greases, be sure to use a general all-purpose grease with an NLGI grade No.2 rating.

Wet or high speed conditions may require use of a special-use grease. Contact your Servicing dealer for information.

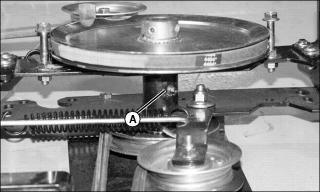

Lubricating Drive Sheave Bearing

Lubricate bearing grease fitting (A) with one or two shots of John Deere Multipurpose Grease or an equivalent until grease comes out of seals.

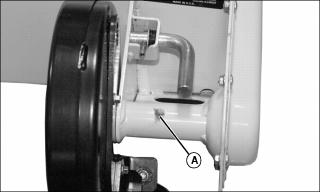

Lubricating Rear Jackshaft

Lubricate shaft grease fitting (A) with two or three shots of John Deere Multipurpose Grease or an equivalent.

Lubricating the Chain

NOTE: Do not perform this procedure unless you are replacing parts.

1. Clean old grease from chain and shield.

3. Remove glue that holds shield to tiller.

4. Coat chain with John Deere Moly High Temperature Grease or an equivalent. Work grease into chain with your hand.

5. Put 0.5 kg (1 lb) of grease inside chain shield.

6. Remove old glue from shield. Apply fresh glue to shield. (See your John Deere dealer for the correct glue.)