Assembly

Identify Parts

Clear Plastic Bag Contains:

Bag of Parts Contains:

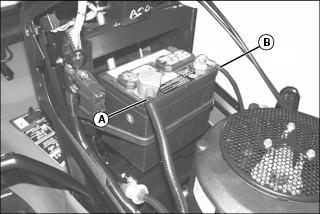

Charge and Connect Battery

1. Remove and discard the red positive (+) protective cap from the positive (+) battery terminal.

· Battery is fully charged at 12.6 volts.

3. Connect positive (+) battery cable (A) to battery.

4. Connect negative (-) battery cable (B).

5. Apply general purpose grease or silicone spray to terminal to help prevent corrosion.

6. Slide red cover over positive battery cable.

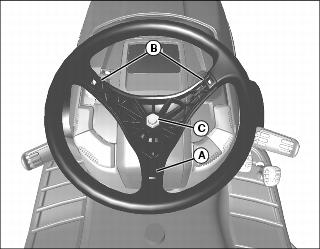

Install Steering Wheel

1. Install steering wheel onto steering shaft. Turn steering wheel to position front wheels straight and facing forward.

3. Put John Deere Multi-Purpose lubricant or an equivalent on the steering shaft.

4. Install steering wheel onto steering shaft with one spindle (A) positioned at 180° at bottom of wheel and spindles (B) at approximately 45° at top of wheel.

5. Install nut (C) and tighten to 38 N·m (28 lb-ft).

6. Install cover (D) so that the logo is on the right side facing up.

Check Tire Pressure

2. Check tire pressure with an accurate gauge.

3. Check that tires have equal air pressure. Add or remove air, if necessary.

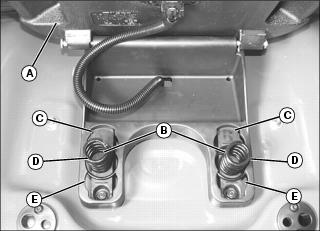

Install Seat Springs

IMPORTANT: Avoid damage! To prevent damage to seat switch and seat base, do not operate without suspension coils in place. |

1. Raise seat (A) and install two springs (B) in one of three slotted areas in seat base.

· Move coils to front position (C) for softest ride.

· Move coils to middle position (D) for average ride.

· Move coils to rear position (E) for firm ride.

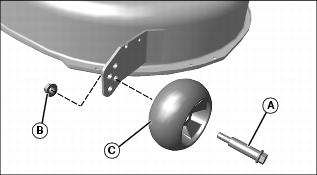

Install Mower Gage Wheels

38 in. and 42 in. Mowers:

NOTE: Gage wheels on 38 in. and 42 in. mowers are not installed in correct hole position for operation.

Picture Note: 38 in. mower shown.

· Remove shoulder bolt (A) and nut (B). Move wheel (C) to proper hole position. Secure with shoulder bolt and nut. Tighten nut to 34 N·m (25 lb-ft).

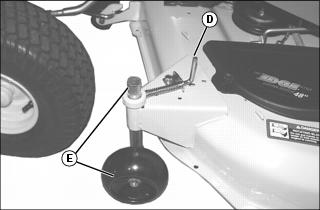

48 in. and 54 in. Mowers:

NOTE: Gage wheels on 48 in. and 54 in. mowers are located upside down on mower deck for shipping.

· Pull pin (D) outward and remove wheel and shaft (E) installed upside down on mower deck. Install from the bottom of deck to proper hole position, as shown. Release pin to lock wheel in position.

2. Adjust mower level before operation.

Test Safety Systems

The safety systems installed on your machine should be checked before each machine use. Be sure you have read the machine operator manual and are completely familiar with the operation of the machine before performing these safety system checks.

Use the testing procedures in the Operating section of this manual to check for normal operation of machine.

If there is a malfunction during one of these procedures, do not operate machine. See your authorized dealer for service.

Perform these tests in a clear open area. Keep bystanders away.