Service Transmission

Transmission Oil

NOTE: Machine is filled with John Deere Low Viscosity HY-GARD® (J20D) transmission oil at the factory. DO NOT mix oils.

These machines are equipped with a internal wet disc brake transmission. Use only Low Viscosity HY-GARD (J20D) transmission oil. DO NOT use type “F” automatic transmission fluid.

IMPORTANT: Avoid damage! Use John Deere Low Viscosity HY-GARD (J20D) transmission oil to reduce transmission noise and to increase response time for the hydraulics and power steering. |

John Deere Low Viscosity HY-GARD (J20D) transmission oil is specially formulated to provide maximum protection against mechanical wear, corrosion, and foaming.

Checking Transaxle Oil Level

1. Park machine safely. (See Parking Safely in the SAFETY Section.)

IMPORTANT: Avoid damage! Contamination of oil could cause transmission damage or failure. Clean area around dipstick before removing. |

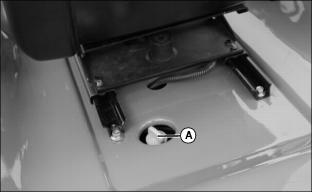

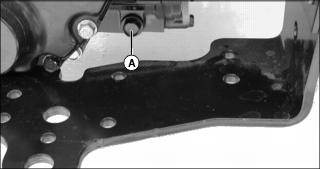

3. Remove dipstick (A) and wipe it with a clean rag.

4. Install dipstick until it rests on top of fill tube. Do not tighten dipstick.

6. Check oil level on dipstick. Oil level should be between crosshatch marks on dipstick.

7. If oil is low, add John Deere Low Viscosity HY-GARD (J20D) transmission oil through dipstick fill opening to proper level.

8. Install and tighten dipstick.

9. Start and run engine a few minutes.

10. Stop engine and check oil level. Add oil as needed.

11. Return seat to operating position.

Changing Transaxle Oil and Filter

1. Park machine safely. (See Parking Safely in the SAFETY Section.)

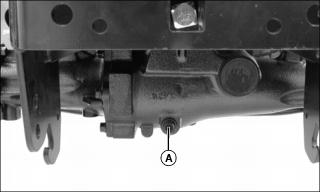

2. Place drain pan under drain plug (A). Remove drain plug and drain oil.

3. Install and tighten drain plug.

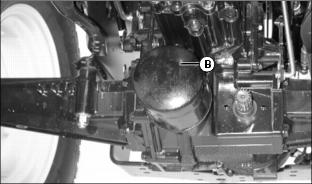

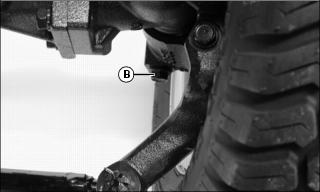

4. Put drain pan under transaxle filter (B).

5. Turn filter counterclockwise with a filter wrench to remove it.

6. Put a film of clean transmission oil on gasket of new filter.

7. Install filter. Turn filter clockwise until gasket contacts the mounting surface. Tighten 2/3 to 1 turn more.

IMPORTANT: Avoid damage! Contamination of oil could cause transmission damage or failure. Clean area around dipstick before removing. |

9. Remove dipstick. Add John Deere Low Viscosity HY-GARD (J20D) transmission oil through dipstick fill opening:

10. Install and tighten dipstick.

11. Start engine and check for oil leaks around filter base and drain plug.

12. Return seat to operating position, and drive machine forward and backward a few times.

13. Stop engine. Wait a minimum of three minutes for transaxle to get cold.

14. Check oil level. Add oil as needed.

Checking Front Axle Oil Level

IMPORTANT: Avoid damage! Allow oil one hour to settle before checking level to ensure accurate dipstick reading. Repeat oil level check after several hours of operation. |

1. Park machine safely. (See Parking Safely in the SAFETY section.) Allow machine to cool down for at least one hour.

IMPORTANT: Avoid damage! Dirt and debris in oil may cause damage to the transaxle. Clean area around opening before removing dipstick. |

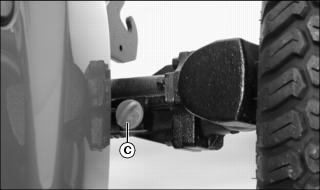

2. Remove dipstick (A) located on right side of front axle.

3. Wipe dipstick with a clean rag. Install and tighten dipstick.

4. Remove dipstick again. Oil level should be at fill mark. If oil level is low:

a. Add John Deere GL-5 Gear Lubricant (80W-90) through dipstick fill opening until oil level is correct.

b. Install and tighten dipstick.

5. Check front axle oil level again after several hours of operation.

Changing Front Axle Oil

1. Operate machine to warm front axle oil.

2. Park machine safely. (See Parking Safely in the SAFETY section.)

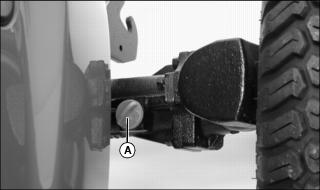

3. Put drain pan under drain plug (A) in center of front axle.

4. Remove drain plug and allow oil to drain.

5. Put drain pan under drain plug (B) on both sides of front axle.

6. Remove drain plugs and allow oil drain.

7. Install and tighten drain plugs (A) and (B) after all oil has drained.

IMPORTANT: Avoid damage! Dirt and debris in oil may cause damage to the transaxle. Clean area around opening before removing dipstick. |

8. Remove dipstick (C) located on right side of front axle.

9. Add approximately 2.4L (2.5 qt) of John Deere GL-5 Gear Lubricant (80W-90) into dipstick filler opening.