Service

Maintenance Tips

• The key to years of trouble-free service is to keep your spreader clean and dry.

• Never allow material to remain in hopper for extended periods of time.

• Should rust develop, sand lightly and then paint area with enamel.

• Periodically check all fasteners for tightness.

• Rinse/dry inside and outside of spreader after each use. Move flow control as you rinse, to avoid build up of material.

Lubrication Intervals

Under normal operating conditions, lubricate spreader three-to-four times a year. Lubricate more often if frequently operated under adverse conditions.

Recommended Lubricants

Use John Deere Multi-Purpose Lithium Grease

Lubricate Bushings and Bearing Surfaces

Apply John Deere Aerosol Silicone Spray Lubricant to:

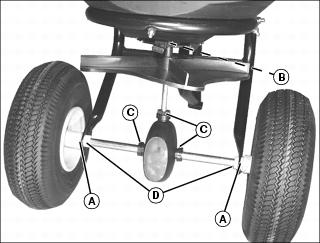

Picture Note: 80 lb spreader shown.

• Axle/Frame bushings (A) (remove and wipe)

• Gear housing bearing surfaces (C)

• Idler wheel hub (D) (or bushings—if equipped).

Lubricate Drive Gears

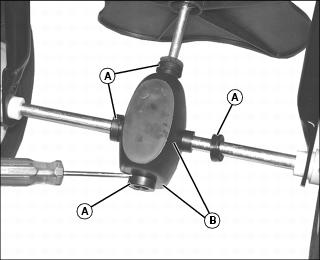

80 lb Spreader

1. Remove four housing retainers (A) and gear housings (B).

2. Apply John Deere Multi-Purpose Lithium Grease to:

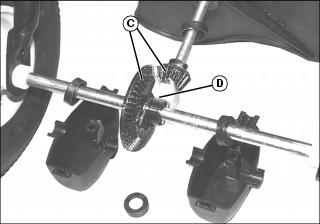

• Bevel and pinion gear surfaces (C)

• Pinion gear support-to-axle (D)

125 and 175 lb Spreaders

1. Lubricate gearbox by applying 3-4 shots of grease into grease fitting (A).