Service Lubrication

Grease

The following greases are preferred:

• John Deere Multi-Purpose SD Polyurea Grease

• John Deere Multi-Purpose HD Lithium Complex Grease

If not using any of the preferred greases, be sure to use a general all-purpose grease with an NLGI grade No.2 rating.

Wet or high speed conditions may require use of a special-use grease. Contact your Servicing dealer for information.

Lubricating Mower Deck Spindles

NOTE: Removal of belt shields is not necessary to lubricate the spindles.

1. Remove mower deck foot plate.

2. Lubricate the mower deck spindles, as indicated.

42 in. Mower Deck

• Lubricate two mower deck spindle grease fittings (A) with two pumps of grease at specified interval.

48 in. Mower Deck (Z245)

Picture Note: Shown with belt covers removed.

• Lubricate three mower deck spindle grease fittings (B) with two pumps of grease at specified interval. The two outer belt covers have a raised area, toward rear of deck, to allow access to grease fittings with the covers installed. Covers can be removed for easier access to the fittings. Install covers if removed.

48 and 54 in. Mower Decks (Z400 Series)

• Lubricate three mower deck spindle grease fittings (C) with two pumps of grease at specified interval.

62 in. Mower Deck

• Lubricate three mower deck spindle grease fittings (D) and idler arm (E) with two pumps of grease at specified interval.

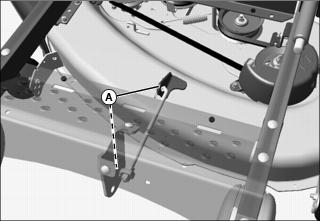

Lubricating Front Lift Arm

Picture Note: Z225 42 in. deck shown.

Picture Note: Z400 series 48 in. deck shown.

Lubricate the front lift arm at the points (A) where it pivots in the mower deck bracket as needed to prevent or minimize squeaking during operation.

Lubricating Front Caster Spindles

• The two front caster wheel supports (A) utilize sealed bearings, which do not require lubrication. There are no grease fittings in the wheel supports.

• The caster wheel yoke spindle (B) should be lightly greased prior to assembly if the wheel unit is serviced, to prevent the spindle from seizing in the bearings.