Service Steering & Brakes

Brake Fluid

The following heavy duty brake fluid is PREFERRED for all drum and disc brakes:

Other brake fluids may be used if they provide the following:

• Conforms to Motor Vehicle Safety Standard No. 116.

• Minimum wet boiling point 155?C (311?F).

• Minimum dry boiling point 230?C (446?F) to prevent vapor lock.

Checking Brake Fluid Level

1. Park vehicle safely. (See Parking Safely in the SAFETY section.)

NOTE: Do not overfill reservoir. If you do overfill, leakage can occur.

3. Visually check brake fluid reservoir. Brake fluid level must be between “MIN” (A) and “MAX” (B) marks. If fluid is low:

• Carefully clean area around reservoir cap (C).

• Remove reservoir cap and add fluid to the “MAX” mark.

Checking Brake Pads

1. Park machine safely. (See Parking Safely in the SAFETY section.)

IMPORTANT: Avoid damage! Place jack stands under frame, not under transmission or engine, when raising or supporting machine. |

2. Raise machine with a safe lifting device and lower machine onto jack stands or other stable supports. Block wheels remaining on the ground to prevent machine movement.

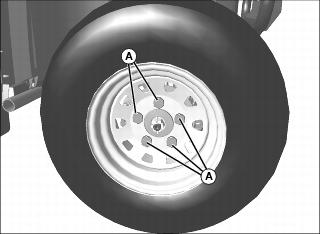

Picture Note: Wheel may or may not have a cap to remove when removing the wheel.

3. Remove the wheel bolts (A).

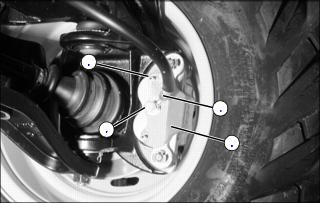

5. Inspect brake pad’s friction material (B) for wear or damage. Check each pad’s friction material thickness: Minimum specification should be 1 mm (3/64 in.). If below this specification or brake pad friction material is damaged, see your John Deere dealer for replacement service.

6. Install wheel assembly with valve stem to the outside.

7. Tighten wheel bolts evenly in alternating sequence until snug.

8. Repeat procedure for remaining three wheels.

9. Lower machine completely to the ground.

• Standard wheel assembly - 108 N•m (80 lb-ft)

• Sport wheel assembly - 142 N•m (105 lb-ft)

Checking Park Brake Fluid

1. Park Machine safely on a level surface. (See “Park Machine Safely” in the SAFETY section.)

2. Raise and secure cargo box.

Picture Note: View from right rear side of vehicle.

3. Remove hex socket plug (A) to check lubricant level in park brake housing. Fluid level should be at bottom of plug opening.

4. If not at proper level, loosen clamp (B) and remove hose (C) from fitting (D). Remove fitting (D). Add recommended fluid until at bottom of plug (A) opening. Install plug (A).

5. Install fitting (D), and hose (C) with clamp (B).

Checking Brake Lines

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Protect any painted surfaces from expelled brake fluid and wipe any areas of excess brake fluid.

4. Check brake line fittings (A) at bottom of reservoir (B) for leaks.

5. Tighten brake line fitting banjo bolts, as needed, to 27 N•m (20 lb-ft).

6. Rotate wheels to provide access to brake calipers.

NOTE: Each caliper has two bleeder screws. If bleeding brakes is necessary, use only the upper screw (F) to bleed brake calipers.

7. Inspect lower brake line fitting (C) on each brake caliper (D) for leaks. Tighten brake line fitting banjo bolt (E), as needed, to 27 N•m (20 lb-ft).

9. Start vehicle and press brake pedal. If leaks are still found, see your John Deere Dealer for service.