Safety

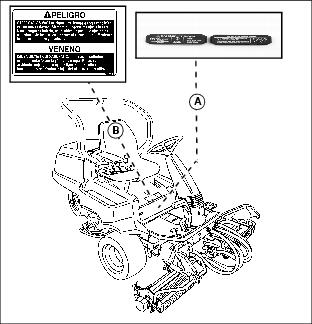

Understanding The Machine Safety Labels

The machine safety labels shown in this section are placed in important areas on your machine to draw attention to potential safety hazards.

On your machine safety labels, the words DANGER, WARNING, and CAUTION are used with this safety-alert symbol. DANGER identifies the most serious hazards.

The operator's manual also explains any potential safety hazards whenever necessary in special safety messages that are identified with the word, CAUTION, and the safety-alert symbol.

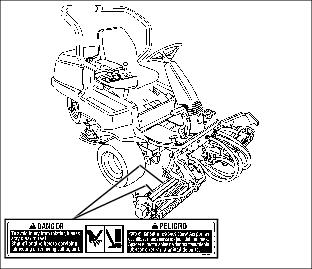

DANGER

Picture Note: Two safety labels attached to each cutting reel.

To avoid injury from rotating blades, stay clear of reel.

Shut off engine before servicing, lubricating or removing cutting unit.

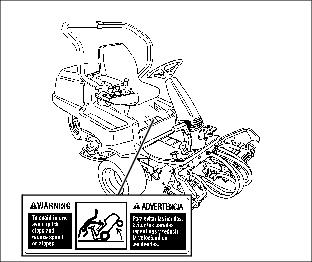

WARNING

To avoid injury, avoid quick stops and reduce speed on slopes.

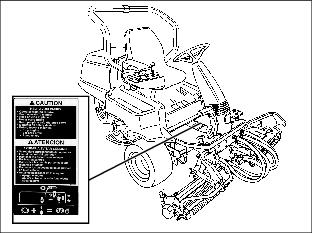

CAUTION

HELP AVOID INJURY

· Keep people a safe distance away.

· Maintain all safety devices.

WARNING

Picture Note: Safety label attached to top of radiator.

DANGER/POISON

Picture Note: Raise operator seat to locate battery safety information. English DANGER/POISON information (A) molded into battery caps. Spanish label (B) is attached to the front of the battery.

NO

Keep out of reach of children. Do not tip. Keep vent caps tight and level.

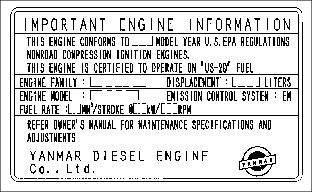

Emissions Control System Certification Label (NonRoad Diesel)

The emissions warranty described in the warranty section applies only to those engines marketed by John Deere that have been certified by the United States Environmental Protection Agency (EPA) and/or California Air Resources Board (CARB); and used in the United States in non-road mobile (self-propelled or portable/transportable1) equipment. The presence of an emissions label like the one shown signifies that the engine has been certified with the EPA and/or CARB. The EPA and CARB warranties only apply to new engines having the certification label affixed to the engine and sold as stated above in the geographic areas governed by the regulating agencies.

NOTE: The hp/kW rating on the engine emissions certification label specifies the gross engine hp/kW, which is flywheel power without fan. In most applications this will not be the same rating as the advertised vehicle hp/kW rating.

Emission Control System Certification Label (Small Off-Road Gas Engines)

NOTE: Tampering with emission controls and components by unauthorized personnel may result in severe fines or penalties. Emission controls and components can only be adjusted by EPA and/or CARB authorized service centers. Contact your John Deere Commercial and Consumer Equipment Retailer concerning emission controls and component questions.

The presence of an emissions label signifies that the engine has been certified with the United States Environmental Protection Agency (EPA) and/or California Air Resources Board (CARB).

The emissions warranty applies only to those engines marketed by John Deere that have been certified by the EPA and/or CARB; and used in the United States and Canada in off-road mobile equipment.

Emission Compliance Period (Small Off-Road Gas Engines)

If your engine has the emission compliance category listed on the emission control system certification or air index label, this indicates the number of operating hours for which the engine has been certified to meet EPA and/or CARB emission requirements. The following table provides the engine compliance period in hours associated with the category found on the certification label.

Canadian Electromagnetic Compatibility (EMC) Compliance

This spark ignition system complies with Canadian ICES-002.

Operator Training Required

· The owner of the machine is responsible for training the users of the machine.

· The owner/user can prevent accidents with proper use of the machine. The owner/user is responsible for accidents or injuries occurring to themselves, other people or property.

· Do not allow operation of the machine by untrained persons.

· Read the operator manual and study the safety and operation sections before operating the machine.

· If the operator of the machine cannot read or understand this manual, the machine owner is responsible to explain this material to the operator. This publication is available in other languages.

· Operate the machine in an open, unobstructed area under the direction of an experienced operator.

· Learn the use of all controls.

· Operator practice is required to learn the moving, stopping, turning and other operating characteristics of the machine.

Operating Safely

· Only allow responsible adults, who are familiar with the instructions to operate the machine. Local restrictions may restrict the age of the operator.

· Inspect machine before you operate. Be sure hardware is tight. Repair or replace damaged, badly worn, or missing parts. Replace faulty silencers. Be sure guards and shields are in good condition and fastened in place. Make any necessary adjustments before you operate.

· Before using, always visually inspect to see that the blades, blade bolts and the mower assembly are not worn and damaged. Replace worn and damaged blades and bolts in sets to preserve balance.

· Be sure all drives are in neutral and parking brake is locked before starting engine. Only start engine from the operator's position.

· Do not change the engine governor settings or overspeed the engine. Operating the engine at excessive speed can increase the hazard of personal injury.

· Do not operate mower without discharge chute or entire grass catcher in place. Never operate with the discharge deflector raised, removed, or altered, unless using a grass catcher.

· Check brake action before you operate. Adjust or service brakes as necessary.

· Stop machine if anyone enters the area.

· If you hit an object or if abnormal vibration occurs, stop and inspect the machine. Make repairs before you operate. Keep machine and attachments properly maintained and in good working order.

· Be aware of the mower discharge direction and make sure that no one is in the path of the discharge direction.

· Do not leave machine unattended when it is running.

· Only operate during daylight or with good artificial light.

· Stop the blades rotating before crossing surfaces other than grass.

· Use only accessories and attachments approved by the manufacturer of the machine. Keep safety labels visible when installing accessories and attachments.

· Do not operate machine if you are under the influence of drugs or alcohol.

· Check before each use that operator presence controls are functioning correctly. Test safety systems. Do not operate unless they are functioning correctly.

· Always wear seat belt if machine has a standard ROPS or a folding ROPS in the upright position.

· Never raise mower decks when blades are running.

· Slow down and be careful of traffic when operating near or crossing roadways. Stop blades before crossing roads or sidewalks. Use care when approaching blind corners, shrubs, trees, or other objects that may obscure vision.

· Do not wear radio or music headphones. Safe service and operation require your full attention.

· Disengage drive to attachments when transporting or not in use.

· Reduce the throttle setting during engine run-out and, if the engine is provided with a fuel shut-off valve, turn the fuel off at the conclusion of mowing.

· When machine is left unattended, stored, or parked, lower the mower deck unless a positive mechanical lock is used.

Using a Spark Arrestor

The engine in this machine is not equipped with a spark arrestor muffler. It is a violation of California Public Resource Code Section 4442 to use or operate this engine on or near any forest-covered, brush-covered or grass-covered land unless the exhaust system is equipped with a spark arrestor meeting any applicable local or state laws. Other states or federal areas may have similar laws.

A spark arrestor for your machine may be available from your authorized dealer. An installed spark arrestor must be maintained in good working order by the operator.

Parking Safely

· Stop machine on a level surface, not on a slope.

· Move the Mow/Transport lever to the TRANSPORT position to disengage reels.

· Push the Raise/Lower lever forward to lower the cutting units.

· Before you leave the operator's location, wait for engine and all moving parts to stop.

Checking Mowing Area

· Evaluate the terrain to determine what accessories and attachments are needed to properly and safely perform the job.

· Clear mowing area of objects that might be thrown. Keep people and pets out of mowing area.

· Low-hanging branches and similar obstacles can injure the operator or interfere with mowing operation. Before mowing, identify potential obstacles such as low-hanging branches, and trim or remove those obstacles.

· Study mowing area. Set up a safe mowing pattern. Do not mow where traction or stability is doubtful.

· Test drive area with mower lowered but not running. Slow down when you travel over rough ground.

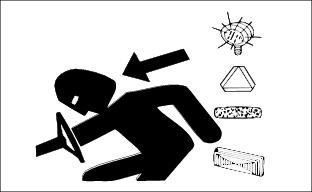

Rotating Blades are Dangerous

Help Prevent Serious Or Fatal Accidents:

· Rotating blades can cut off arms and legs, and throw objects. Failure to observe safety instructions could result in serious injury or death.

· Keep hands, feet and clothing away from attachment when engine is running.

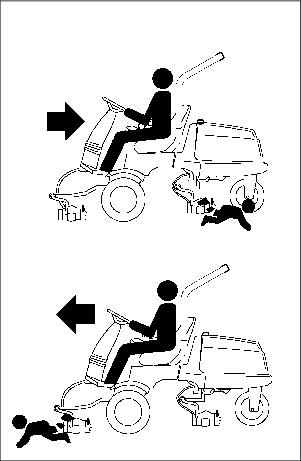

· Be alert at all times, drive forward carefully. People, especially children can move quickly into the mowing area before you know it.

· Before backing up, shut off PTO and look down and behind the machine carefully, especially for children.

· Shut off blades when you are not mowing.

· Park machine safely before leaving the operator's station for any reason including emptying the grasscatchers or unplugging the chute.

Protect Children:

· Never assume that children will remain where you last saw them. Children are attracted to machine activity, stay alert to the presence of children.

· Keep children out of the area when you are operating. Turn the machine off if a child enters the mowing area.

· Use extra care when you come to blind corners, shrubs, trees, or other objects that may block your vision.

· Do not let children or an untrained person operate the machine.

· Do not carry or let children ride on machine or any attachment even with the blades off. Do not tow children in a cart or trailer.

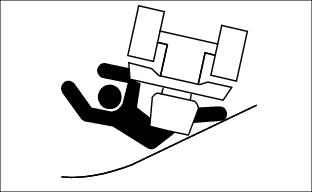

Avoid Tipping

· Slopes are a major factor related to loss-of-control and tip-over accidents, which can result in severe injury or death. All slopes require extra caution. If you cannot back up the slope or if you feel uneasy on it, do not mow it.

· Drive up and down a hill - not across.

· Do not mow or operate on slopes you cannot back up.

· Keep all movement on slopes slow and gradual. Do not make sudden changes in speed or direction.

· Use a slow speed when operating on a slope. Choose a low gear or speed so that you will not have to stop or shift while on the slope.

· Tires may lose traction on slopes even though the brakes are functioning properly.

· Do not turn on slopes unless necessary. Turn slowly and turn downhill. Do not shift to neutral and coast downhill.

· Stay alert for holes and other hidden hazards in the terrain. Uneven terrain could overturn the machine. Tall grass can hide obstacles.

· Keep away from drop-offs, ditches and embankments. The machine could suddenly turn over if a wheel is over the edge of a cliff or ditch, or if an edge caves in.

· Use extra care with grass catchers or other attachments. These can change the stability of the machine. Do not use grass catcher on steep slopes.

· Follow the manufacturer's recommendations for wheel weights or counterweights for added stability when operating on slopes or using front or rear mounted attachments. Remove weights when not required.

· Do not stop when going up hill or down hill. If machine stops going up hill or tires lose traction, disengage mower blades and back down slowly.

· Operating machine when grass is wet can cause reduced traction and sliding.

· Do not try to stabilize the machine by putting your foot on the ground.

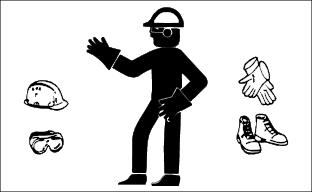

Wear Appropriate Clothing

· Wear close fitting clothing and safety equipment appropriate for the job.

· Always wear safety goggles, or safety glasses with side shields, and a hard hat when operating the mower.

· Wear a suitable protective device such as earplugs. Loud noise can cause impairment or loss of hearing.

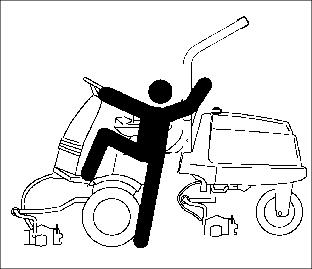

Keep Riders Off

· Only allow the operator on the machine. Keep riders off.

· Riders on the machine or attachment may be struck by foreign objects or thrown off the machine causing serious injury.

· Riders obstruct the operator's view resulting in the machine being operated in an unsafe manner.

Mount and Dismount Safely

· Do not step on pedals when mounting or dismounting.

· Keep step area and platform clean.

· Stop machine, move Mow/Transport lever to transport position, lower cutting units to the ground, lock park brake, stop engine, remove key, and wait for all moving parts to stop before dismounting.

Transport Safely

· Use safety lights and devices. Slow-moving machines when driven on public roads are hard to see, especially at night. Avoid personal injury or death resulting from a collision with a vehicle.

· Flashing warning lights are recommended whenever driving on public roads to increase visibility. Extra flashing warning lights may need to be installed.

Checking Wheel Bolts

· A serious accident could occur causing serious injury if wheel bolts are not tight.

· Check wheel bolt tightness often during the first 100 hours of operation.

· Wheel hardware must be tightened to specified torque using the proper procedure anytime it is loosened.

Avoid Neutral Creep

· The machine may creep forward or backward while in neutral with engine running.

· After engine has started, unlock park brake and with directional speed control speed pedals centered, machine should not move.

· If movement is evident, neutral return mechanism is adjusted incorrectly.

Avoid High Pressure Fluids

· Hydraulic hoses and lines can fail due to physical damage, kinks, age, and exposure. Check hoses and lines regularly. Replace damaged hoses and lines.

· Hydraulic fluid connections can loosen due to physical damage and vibration. Check connections regularly. Tighten loose connections.

· Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid the hazard by relieving pressure before disconnecting hydraulic or other lines. Tighten all connections before applying pressure.

· Search for leaks with a piece of cardboard. Protect hands and body from high pressure fluids.

· If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury should reference a knowledgeable medical source. Such information is available from Deere & Company Medical Department in Moline, Illinois, U.S.A. Information may be obtained in the United States and Canada only by calling 1-800-822-8262.

Practice Safe Maintenance

· Only qualified, trained adults should service this machine.

· Understand service procedure before doing work. Keep area clean and dry.

· Do not operate the engine in a confined space where dangerous carbon monoxide fumes can collect.

· Never lubricate, service, or adjust machine while it is moving. Keep safety devices in place and in working condition. Keep hardware tight.

· On multi-bladed machines, take care as rotating one blade can cause other blades to rotate.

· Keep hands, feet, clothing, jewelry, and long hair away from any moving parts, to prevent them from getting caught.

· Lower attachments to the ground before cleaning or servicing machine. Disengage all power and stop the engine. Lock park brake and remove the key. Let machine cool.

· Disconnect battery or remove spark plug wire (for gasoline engines) before making any repairs.

· Before servicing machine, carefully release pressure from any components with stored energy, such as hydraulic components.

· Keep all nuts and bolts tightened, especially blade attachment bolts.

· Securely support any machine elements that must be raised for service work. Use jack stands or lock service latches to support components when needed.

· Never run engine unless park brake is locked.

· Use care when checking blades. Wrap blades or wear gloves and use caution when servicing them. Only replace blades. Never straighten or weld them.

· Keep all parts in good condition and properly installed. Fix damage immediately. Replace worn or broken parts. Replace all worn or damaged safety and instruction decals.

· Grass catcher components are subject to wear, damage, and deterioration which could expose moving parts or allow objects to be thrown. Check components frequently and replace with manufacturer's recommended parts when necessary.

· To prevent fires, remove any buildup of grease, oil, or debris from the machine, especially the engine compartment.

· Charge batteries in an open, well-ventilated area, away from sparks. Unplug battery charger before connecting or disconnecting from the battery. Wear protective clothing and use insulated tools.

· Do not modify machine or safety devices. Unauthorized modifications may impair its function and safety.

· Check brake operation frequently. Adjust and service as needed.

Prevent Fires

· Never remove fuel cap, or add fuel with engine running or hot. Allow engine to cool for several minutes.

· Never store equipment with fuel in the tank inside a building where fumes may reach an open flame or spark.

· Allow engine to cool before storing in any enclosure.

· To reduce fire hazard, keep engine free of grass, leaves, or excessive grease.

Tire Safety

Explosive separation of a tire and rim parts can cause serious injury or death:

· Do not attempt to mount a tire without the proper equipment and experience to perform the job.

· Always maintain the correct tire pressure. Do not inflate the tires above the recommended pressure. Never weld or heat a wheel and tire assembly. The heat can cause an increase in air pressure resulting in a tire explosion. Welding can structurally weaken or deform the wheel.

· When inflating tires, use a clip-on chuck and extension hose long enough to allow you to stand to one side and NOT in front of or over the tire assembly.

· Check tires for low pressure, cuts, bubbles, damaged rims or missing lug bolts and nuts.

Handling Fuel Safely

Fuel and fuel vapors are highly flammable:

· Do not refuel machine while you smoke, when machine is near an open flame or sparks, or when engine is running. Stop engine and allow to cool before filling.

· Never remove the fuel cap or add fuel with the engine running.

· Replace all fuel tanks and container caps securely.

· Never fill fuel tank or drain fuel from a machine in an enclosed area. Fill fuel tank outdoors.

· Prevent fires. Clean up spilled fuel immediately. If fuel is spilled on clothing, change clothing immediately. Do not attempt to start the engine but move the machine away from the area of spillage and avoid creating any source of ignition until fuel vapors have dissipated.

· Do not store fuel in container or machine with fuel in tank in a building where fumes may reach an open flame or spark.

· Prevent fire and explosion caused by static electric discharge. Use only non-metal, portable fuel containers approved by the Underwriter's Laboratory (U.L.) or the American Society for Testing & Materials (ASTM). If using a funnel, make sure it is plastic and has no screen or filter.

· Static electric discharge can ignite gasoline vapors in an ungrounded fuel container. Remove the fuel container from the bed of a machine or trailer or the trunk of a car and place on the ground away from the machine before filling. Keep nozzle in contact with container opening while filling. Do not use a nozzle lock-open device.

· When practical, remove equipment from trailers or truck beds and refuel them on the ground. If this is not possible, use a portable, plastic fuel container to refuel equipment on a truck bed or trailer.

· For gasoline engines, do not use gas with methanol. Methanol is harmful to your health and to the environment.

Handling Waste Product and Chemicals

Waste products, such as, used oil, fuel, coolant, brake fluid, and batteries, can harm the environment and people:

· DO NOT use beverage containers for waste fluids - someone may drink from them.

· See your local Recycling Center or John Deere dealer to learn how to recycle or get rid of waste products.

· A Material Safety Data Sheet (MSDS) provides specific details on chemical products: physical and health hazards, safety procedures, and emergency response techniques. The seller of the chemical products used with your machine is responsible for providing the MSDS for that product.