Service Lubrication

Grease

The following greases are preferred:

• John Deere Multi-Purpose SD Polyurea Grease

• John Deere Multi-Purpose HD Lithium Complex Grease

• John Deere Moly High Temperature EP Grease

If not using any of the preferred greases, be sure to use a general all-purpose grease with an NLGI grade No.2 rating.

Wet or high speed conditions may require use of a special-use grease. Contact your Servicing dealer for information.

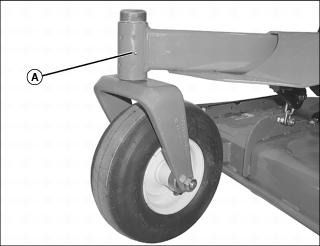

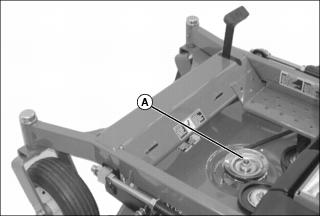

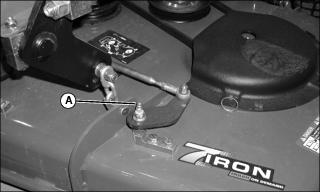

Lubricating Front Caster Spindles

NOTE: Do not over lubricate. Excess grease could fall from mower during operation.

Clean grease fitting before lubricating. Replace missing or broken grease fittings immediately.

• Lubricate two front caster spindle grease fittings (A).

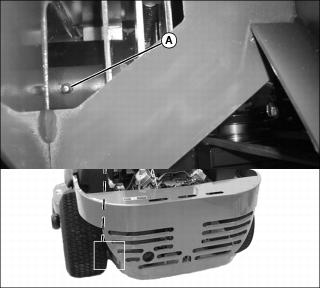

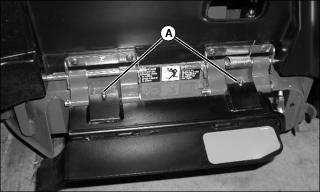

Lubricating Deck Lift Support Blocks

NOTE: Adjust the mower deck to a lower cutting height position when performing this service procedure.

• Lubricate four deck lift support block grease fittings (A).

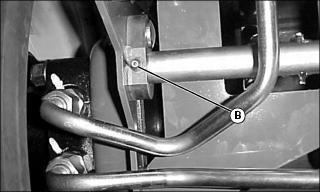

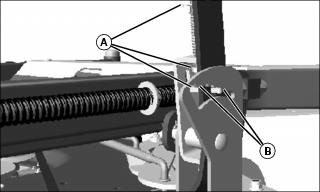

Lubricating Park Brake Assemblies

1. Unlock park brake before lubricating park brake assembly.

2. Lubricate two rear park brake assembly grease fittings (A), located under each side of the machine, behind the tires.

3. Lower the mower deck to the lowest position to access the front park brake assembly grease fitting.

4. Lubricate two front park brake assembly grease fittings (B), located on the brake shaft on each side of the machine.

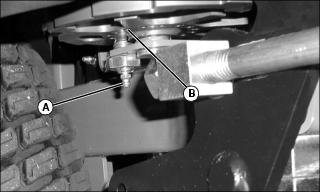

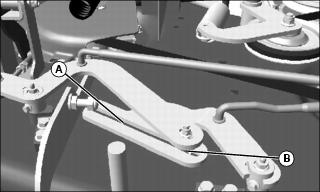

Lubricating Height-of-Cut Ball Detent

• Lubricate one deck lift pivot grease fitting (A) between two height-of-cut notches (B).

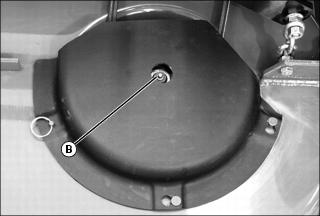

Lubricating Mower Deck Spindles

NOTE: Removal of the belt shields is not necessary to lubricate the spindles.

• Lubricate one mower deck spindle grease fitting (A), located in the center of the deck.

• Lubricate two mower deck spindle grease fittings (B), located on either side of the mower deck.

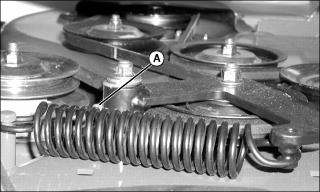

Lubricating Mower Deck Idler Pivot

1. Remove mower deck foot plate.

2. Lubricate one deck idler pivot grease fitting (A).

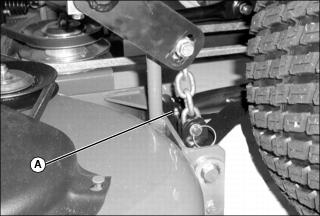

Lubricating Mower Deck Push Arms

• Lubricate two push arm grease fittings (A), one located on each side of the machine with John Deere Multi-Purpose SD Polyurea Grease or an equivalent.

Mulch-On-Demand Mower Deck: Lubricating Mower Deck Baffle Pivots

• Lubricate four mower deck baffle pivots (A) with John Deere Multi-Purpose SD Polyurea Grease or an equivalent.

Mulch-On-Demand Mower Deck: Lubricating Mower Deck Discharge Gate Pivots

• Lubricate two mower deck discharge gate pivots (A) with John Deere Multi-Purpose SD Polyurea Grease or an equivalent.

Mulch-On-Demand Mower Deck - Lubricating Handle Latch and Gate

• Lubricate handle latch (A) and gate (B) with John Deere Super Lube or similar dry lubricant spray.

Mulch-On-Demand Mower Deck - Lubricating Right Linkage Slot and Pivot

• Lubricate right hand linkage slot (A) and pivot (B) with John Deere Super Lube or similar dry lubricant spray.