Service Lubrication

Grease

The following greases are preferred:

· John Deere Multi-Purpose SD Polyurea Grease

· John Deere Multi-Purpose HD Lithium Complex Grease

· John Deere Moly High Temperature EP Grease

If not using any of the preferred greases, be sure to use a general all-purpose grease with an NLGI grade No.2 rating.

Wet or high speed conditions may require use of a special-use grease. Contact your Servicing dealer for information.

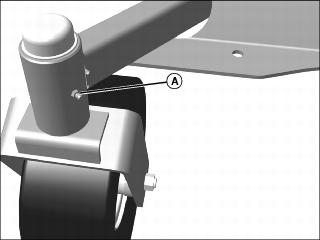

Lubricating Front Caster Spindles

NOTE: Do not over-lubricate. Excess grease could fall from mower during operation.

Clean grease fitting before lubricating. Replace missing or broken grease fittings immediately.

· Lubricate two front caster spindle grease fittings (A).

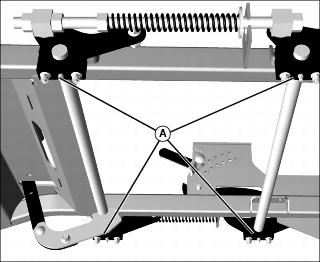

Lubricating Deck Lift Arm Blocks

NOTE: Adjust the mower deck to a lower cutting height position when performing this service procedure.

· Lubricate four deck lift arm block grease fittings (A), two located on each side of the machine.

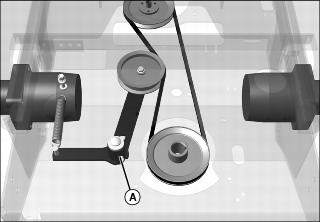

Lubricating Pump Idler Pivot

· Lubricate one pump idler pivot grease fitting (A).

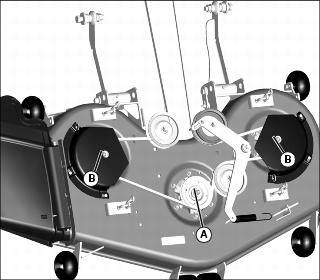

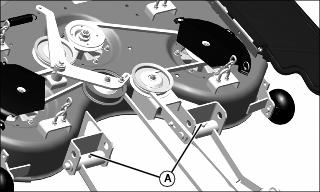

Lubricating Mower Deck Spindles

NOTE: Removal of belt shields and foot plate is not necessary to lubricate the spindles.

· Lubricate one mower deck spindle grease fitting (A), located in the center of the deck.

· Remove grease fitting caps from belt shields located on either side of the mower deck.

· Lubricate two mower deck spindle grease fittings (B).

Lubricating Mower Deck Struts

· Lubricate two push arm grease fittings (A), one located on each side of the machine.