Service Transmission

Transmission and Hydraulic Oil

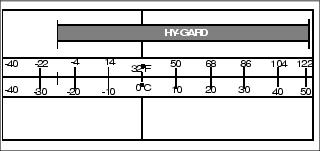

NOTE: Tractor is filled with John Deere HY-GARD™ (J20C) transmission oil at the factory. Do not mix oils. Do not use type “F” automatic transmission fluid or J20D Low Viscosity HY-GARD™.

Use the following oil viscosity based on the air temperature range. Operating outside of the recommended oil air temperature range may cause premature hydrostatic transmission failure.

John Deere HY-GARD™ (J20C) transmission oil is specially formulated to provide maximum protection against mechanical wear, corrosion, and foaming.

Checking Transmission Oil Level

IMPORTANT: Avoid damage! Hot hydraulic oil will expand and show incorrect oil level. Check oil level: |

NOTE: Do not overfill reservoir tank. Oil will expand during operation and could overflow.

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Lift operator seat and lock into position.

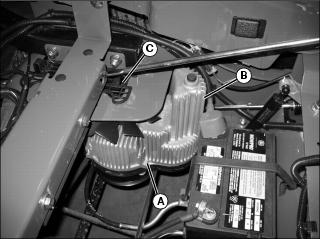

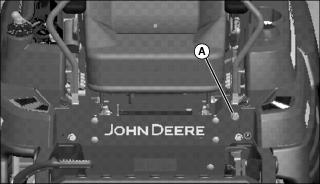

3. Check for oil in sight glass (A).

4. If no oil is in the site glass, remove breather (B) from the transmission oil reservoir.

5. Add oil until oil is seen in the sight glass.

6. Install breather on hydraulic reservoir.

7. Repeat procedure for other transmission.

Changing Transmission Oil and Filter

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Allow engine and transmission oil reservoir to cool.

3. Remove breather from on top of the transmission oil reservoir tank.

4. Remove filter (A) from transmission reservoir and discard.

5. Allow transmission oil to drain into a drain pan.

6. Apply a film of clean oil on gasket of new filter.

7. Install filter into the oil reservoir.

• Be careful not to cross thread filter. Turn filter counterclockwise to seat threads, and then push the filter into the transmission as it is turned clockwise.

8. Fill reservoir until oil can be seen in sight glass.

10. Allow engine to idle for 1 minute at low idle before full throttle.

11. Move throttle lever to the 3/4 fast idle position.

13. Run engine in full throttle for five minutes and then cycle motion control levers forward and rearward several times. Check for leaks around filter.

14. Stop the engine. Check oil level. Add oil as necessary.

Cleaning Transmission Fan and Cooling Fins

• Clear work area of bystanders. • Wear eye protection when using compressed air for cleaning purposes. |

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Clean cooling fins (A) around exterior of transmission and fan (B) with a rag, brush, or compressed air.

3. Clean transmission fan screen (C).

Checking and Replacing Traction Drive Belt

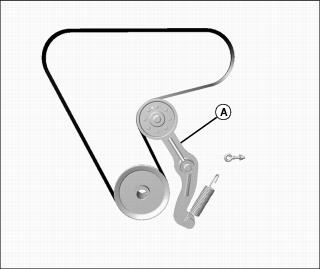

NOTE: The traction drive belt is self-adjusted using a spring tensioner and does not require a tension adjustment.

Checking Belt:

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Inspect belt for excessive wear, damage or stretching while in position on the transmission sheave and drive belt tensioner sheave.

Replacing Belt

1. Remove mower deck belt from clutch pulley.

2. Remove belt from drive sheaves and idler sheave.

• To make removal and installation of the belt easier, carefully rotate the spring loaded idler (A) away from belt.

3. Install belt onto drive sheaves and idler sheave as shown.

Checking and Adjusting Neutral Creep

Checking Motion Control Linkages

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Raise rear of machine only enough for rear tires to rotate freely.

4. Set throttle lever to the fast position.

6. If the rear drive wheels begin to creep, an adjustment is required.

Adjusting Motion Control Linkages

NOTE: Perform adjusts with rear tires off the ground just enough so wheels can rotate.

1. Stop engine and lock park brake.

2. Move both motion control levers (A) to the neutral lock position.

5. Set throttle to fast idle position.

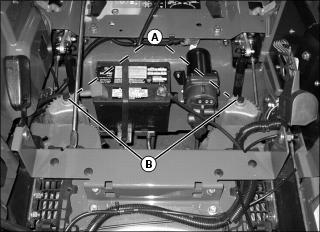

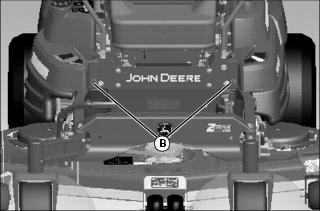

7. Locate left and right motion control linkage adjustment points (B).

8. Be sure the right motion control linkage is in the neutral lock position. The right drive wheel must not turn. If it does turn, adjust the motion control linkage.

Picture Note: Front plate shown removed for clarity.

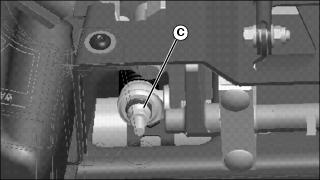

9. Adjust nut (C) on end of steering linkage.

• If wheel is spinning in forward direction, turn nut clockwise to bring wheel to a stop.

• If wheel is spinning in reverse direction, turn nut counter-clockwise to bring wheel to a stop.

10. Move the right motion control lever completely forward and rearward in the slot and then back to the neutral lock-out position.

• The drive wheels will slow down to +/- 4 rpm. If the drive wheels are rotating faster than +/- 4 rpm, repeat step 10.

11. Repeat procedure to adjust the left motion control linkage.

• Drive wheels should not rotate when in neutral lock position.

13. Move both motion control levers to the neutral lock position.

15. Dismount from the machine.

Adjusting Tracking

If the machine does not track in a straight line while going forward, adjust the tracking:

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Turn the adjusting screw as required:

• If machine tracks to right, turn adjusting screw (A) clockwise one rotation.

• If machine tracks to left, turn adjusting screw (A) counter-clockwise one rotation.

3. Test vehicle for proper tracking.

4. Repeat the steps 2 and 3 as necessary to adjust the tracking.