Service Transmission

Transmission and Hydraulic Oil

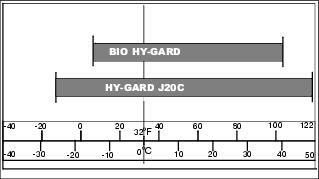

Use oil viscosity based on the expected air temperature range during the period between oil changes.

John Deere J20C HY-GARD Transmission/Hydraulic Oil is recommended.

Use John Deere BIO HY-GARD™ oil when a biodegradable fluid is required.

Other oils may be used if they meet John Deere Standard JDM J20C.

Biodegradable Oil

Application

When use of a biodegradable lubricant is desired or required, BIO HY-GARD is recommended. BIO HY-GARD may be used under normal mowing conditions.

DO NOT USE biodegradable lubricants in machines for the following operations:

• Any machine used for scalping procedure.

• Any verticut operation in temperatures exceeding 32°C (90°F).

• Mixing of biodegradable oil and mineral oil will reduce the biodegradability of the lubricant in the machine. Mixing of HY-GARD and BIO HY-GARD will not result in performance deterioration.

Cold Weather Operation

Precautions should be taken if BIO HY-GARD containers or equipment are stored for long periods of time in extremely cold temperatures. Freezing should be expected if BIO HY-GARD is subjected to the following temperatures:

• Stored for six months at -18° to -23°C (-1° to -10°F)

• Stored for seven days at -23° to -26°C (-10° to -15°F)

• Stored for three days at -26° to -29°C (-15° to -20°F)

• Stored for two days at -29° to -34°C (-20° to -30°F)

• Stored for one day at -34°C (-30°F) and below.

IMPORTANT: Avoid damage! Equipment should not be started or any operation attempted until BIO HY-GARD™ has reached a safe operating viscosity. |

If freezing of BIO HY-GARD is suspected, the container or equipment MUST be warmed to at least 0°C (32°F) and maintained for 24-48 hours to ensure the fluid has reached a safe operating viscosity.

Converting From HY-GARD to BIO HY-GARD

Systems being converted from HY-GARD to BIO HY-GARD should follow the procedure listed below to obtain maximum lubricant biodegradability.

1. Park machine on a level surface.

2. Lower cutting units, stop engine, set park brake and remove key from ignition.

5. Fill reservoir with BIO HY-GARD to appropriate level.

6. Start engine and bring to medium idle.

7. Turn steering wheel full stroke several times and cycle cutting units several times.

8. Stop engine and check hydraulic oil level. Add BIO HY-GARD to appropriate level.

9. Operate machine under normal operating conditions for a minimum of two hours.

11. Follow recommended maintenance schedules.

Adjusting Transmission Neutral

NOTE: The greensmower may creep forward or backward while in neutral position with engine running. If so, an adjustment is needed.

Check Transmission Neutral Adjustment

2. Unlock park brake with transmission in neutral.

3. Adjust neutral return mechanism if machine moves. Adjust until greensmower does not move while machine is in neutral position.

Transmission Neutral Adjustment

1. Park vehicle safely. (See Park Safely in the SAFETY section.)

2. Move mow-transport lever to transport position.

3. Secure operator seat in the raised position.

4. Use safe lifting device to lift front of greensmower so drive wheels are off the ground. Support with jack stands or wooden blocks.

6. Adjust throttle level to slow idle.

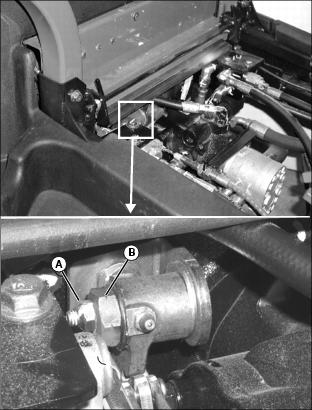

8. Loosen eccentric jam nut (A).

9. Slowly turn eccentric cam (B) clockwise or counterclockwise to stop any drive wheel rotation.

10. Hold eccentric cam and tighten eccentric jam nut.

• Depress and release forward and reverse travel pedals.

• Check turning motion of drive wheels when transmission is in neutral.

• Repeat adjustment until the wheels do not turn when transmission is in neutral.

NOTE: The neutral lock adjustment should be done after the transmission neutral adjustment.

Adjusting Neutral Lock

NOTE: . Transmission neutral adjustment must be completed prior to doing this service adjustment.

Check Position of Neutral Lock Pin

1. Locate neutral lock linkage under the right side of the operator platform.

2. Depress and lock park brake pedal in the first engaged position.

• The neutral lock pin (A) should be engaged into the narrow opening of slot (B) in the forward travel pedal linkage.

• When the park brake is unlocked, the neutral lock pin (A) should be in the wide opening of slot (B). The forward travel pedal should have full forward and full reverse motion within the pedal linkage opening.

4. Adjust the neutral lock if both of these conditions are not met.

Adjust Position of Neutral Lock Pin

1. Locate neutral lock adjustment mechanism under the right side of the operator platform.

2. Loosen jam nut (C) on the neutral lock rod.

3. Remove cotter pin (D) and flat washer (E) from the neutral lock driver arm.

4. Disconnect rod end (F) off of driver arm.

6. Install rod end (F), flat washer (E) and cotter pin (D) onto driver arm.

8. Check neutral lock pin engagement.

Checking and Adjusting Park Brake Neutral

Check Adjustment

1. Depress and lock park brake pedal in the first engaged position.

• The neutral lock pin (A) should be engaged into the narrow opening of slot (B) in the forward travel pedal linkage.

• The forward travel pedal should not move or should lift up slightly when the brake is engaged.

3. Check drive wheels for movement.

• If the drive wheels begin to creep when the brake is set, adjustment is required.

Adjust Park Brake Neutral

2. Use safe lifting device to lift front of greensmower so drive wheels are off the ground. Support with jack stands or wooden blocks.

3. Secure operator seat in the raised position.

4. Depress and lock park brake in the first engaged position.

5. Remove cotter pin (C) and clevis pin (D) connecting the cable linkage yoke (E) to the hydraulic pump lever.

9. Check drive wheel movement.

• If the drive wheels begin to creep with the brake pedal locked in the first engaged position, additional adjustment is necessary. Continue adjustment process until creep is gone.