Service - Hydraulics

Transmission and Hydraulic Oil

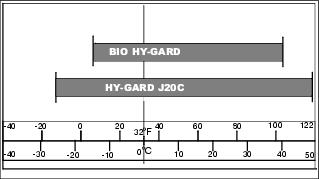

Use oil viscosity based on the expected air temperature range during the period between oil changes.

John Deere J20C HY-GARD Transmission/Hydraulic Oil is recommended.

Use John Deere BIO HY-GARD™ oil when a biodegradable fluid is required.

Other oils may be used if they meet John Deere Standard JDM J20C.

Biodegradable Oil

Application

When use of a biodegradable lubricant is desired or required, BIO HY-GARD is recommended. BIO HY-GARD may be used under normal mowing conditions.

DO NOT USE biodegradable lubricants in machines for the following operations:

• Any machine used for scalping procedure.

• Any verticut operation in temperatures exceeding 32°C (90°F).

• Mixing of biodegradable oil and mineral oil will reduce the biodegradability of the lubricant in the machine. Mixing of HY-GARD and BIO HY-GARD will not result in performance deterioration.

Cold Weather Operation

Precautions should be taken if BIO HY-GARD containers or equipment are stored for long periods of time in extremely cold temperatures. Freezing should be expected if BIO HY-GARD is subjected to the following temperatures:

• Stored for six months at -18° to -23°C (-1° to -10°F)

• Stored for seven days at -23° to -26°C (-10° to -15°F)

• Stored for three days at -26° to -29°C (-15° to -20°F)

• Stored for two days at -29° to -34°C (-20° to -30°F)

• Stored for one day at -34°C (-30°F) and below.

IMPORTANT: Avoid damage! Equipment should not be started or any operation attempted until BIO HY-GARD™ has reached a safe operating viscosity. |

If freezing of BIO HY-GARD is suspected, the container or equipment MUST be warmed to at least 0°C (32°F) and maintained for 24-48 hours to ensure the fluid has reached a safe operating viscosity.

Converting From HY-GARD to BIO HY-GARD

Systems being converted from HY-GARD to BIO HY-GARD should follow the procedure listed below to obtain maximum lubricant biodegradability.

1. Park machine on a level surface.

2. Lower cutting units, stop engine, set park brake and remove key from ignition.

5. Fill reservoir with BIO HY-GARD to appropriate level.

6. Start engine and bring to medium idle.

7. Turn steering wheel full stroke several times and cycle cutting units several times.

8. Stop engine and check hydraulic oil level. Add BIO HY-GARD to appropriate level.

9. Operate machine under normal operating conditions for a minimum of two hours.

11. Follow recommended maintenance schedules.

Checking Hydraulic Oil Level

IMPORTANT: Avoid damage! Hot hydraulic oil will expand and show incorrect oil level. Check reservoir tank: |

1. Park the vehicle safely. (See Park Safely in the SAFETY section.)

IMPORTANT: Avoid damage! Dirt and debris in hydraulic oil may cause damage to the hydraulic system. • Do not open oil reservoir cap unless absolutely necessary. |

NOTE: Check hydraulic oil level when oil is cold.

Make sure main reservoir is full before checking level in secondary reservoir.

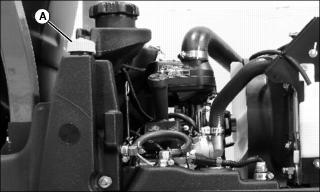

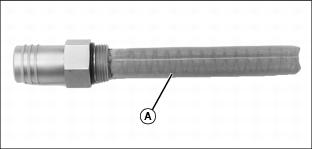

3. Remove reservoir cap and dipstick (A). Wipe with a clean cloth.

4. Install reservoir cap and dipstick.

5. Remove reservoir cap and dipstick.

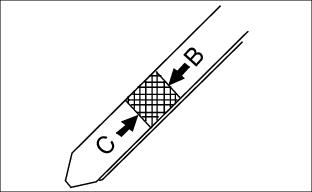

6. Check oil level on dipstick; oil level should be between levels (B) and (C) on the dipstick.

7. If oil is low, add oil to bring oil level no higher than level (B) on the dipstick.

8. If oil level is above level (B) on the dipstick, drain to proper level.

9. Install and tighten reservoir cap and dipstick.

Checking Hydraulic Oil Filter Status Indicator

IMPORTANT: Avoid damage! Hydraulic fluid may begin to break down sooner under severe or unusual conditions. Operating in these conditions may require more frequent service intervals. |

1. Park vehicle safely. (See Park Safely in the SAFETY section.)

2. Secure operator seat in the raised position.

3. Locate and check hydraulic oil filter status indicator (A) just above oil filter.

• When plunger (B) inside indicator moves in direction shown by arrow on indicator and is visible inside the indicator red zone, hydraulic oil filter requires immediate service.

Changing Hydraulic Oil

IMPORTANT: Avoid damage! Dirt and debris in hydraulic oil may cause damage to the hydraulic system. • Do not open oil reservoir cap unless absolutely necessary. |

1. Park the vehicle safely. (See Park Safely in the SAFETY section.)

2. Allow engine and hydraulic oil reservoirs to cool.

4. Place drain pan with at least a 21 L (6 gal) capacity under oil drain location.

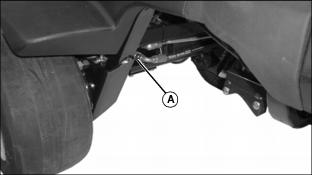

5. Locate and remove drain plug (A) under left side of main oil reservoir to drain oil.

6. Clean hydraulic oil reservoir strainer before adding oil to hydraulic system.

7. Apply thread sealant to drain plug threads.

8. Install and tighten drain plug (A) to 9.5 ± 1.4 N•m (7 ± 1 lb-ft).

NOTE: Auxiliary hydraulic reservoir (B) needs to be removed to drain oil.

9. Disconnect hose (C) at auxiliary reservoir.

10. Remove bolts (D) and remove reservoir.

11. Clean area around auxiliary oil reservoir fill cap (E). Remove cap. Drain oil out of fill neck.

12. Install reservoir and connect hose.

NOTE: Total oil capacity of hydrostatic and reel drive system is 28.8 L (7.6 gal). Capacity of hydraulic oil reservoir is ONLY 20.4 L (5.4 gal).

• Clean area around reservoir fill plug (F).

• Fill reservoir with oil. Do not over fill.

• Apply thread sealant to main fill plug threads.

• Install and tighten fill plug to 27 ± 5.5 N•m (20 ± 4 lb-ft).

14. Fill auxiliary oil reservoir.

• Add oil at reservoir fill cap location. Oil level should be between HOT and COLD marks on the dipstick.

16. Cycle hydraulic controls for one or two minutes. Check for leaks.

18. Check oil level. Add oil as necessary.

Changing Hydraulic Oil Filter

1. Park vehicle safely. (See Park Safely in the SAFETY section.)

2. Allow engine and hydraulic oil filter to cool.

3. Secure operator seat in the raised position.

4. Locate hydraulic oil filter (A) under right side of greensmower.

5. Turn filter counterclockwise to remove.

6. Apply a film of clean oil on gasket of new filter.

7. Turn filter clockwise until gasket makes contact with the mounting surface. Tighten 1/2 to 3/4 turn after gasket contact.

9. Cycle hydraulic controls for one or two minutes. Check for leaks.

11. Check oil level. Add oil as necessary.

Cleaning Hydraulic Oil Reservoir Strainer

NOTE: Clean hydraulic oil reservoir strainer when changing the hydraulic oil and filter. Service strainer when the hydraulic oil reservoir is empty.

1. Change hydraulic oil and filter.

2. Locate hydraulic oil reservoir strainer (A) under left side of machine.

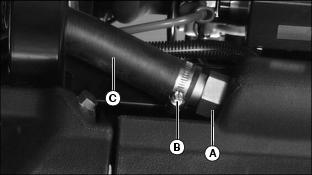

3. Loosen adjustable hose clamp (B).

NOTE: Use drain pan to catch dripping oil.

4. Remove rubber hose (C) from strainer.

5. Loosen and remove strainer from reservoir housing.

6. Clean strainer (A) with solvent or mineral spirits.

8. Apply thread sealant to strainer threads.

9. Install strainer into reservoir housing and tighten to 27-34 N•m (20-25 lb-ft).

10. Install rubber hose (C) onto strainer.

11. Install and tighten adjustable hose clamp (B).

Cleaning Backlap/Mower Valve Screen

NOTE: Same Process can be used to clean lift valve.

1. Park the machine safely. (See Parking Safely in the SAFETY section.)

2. Allow hydraulic oil to cool.

3. Locate backlap/mow valve under left side of greensmower.

NOTE: Use drain pan to catch dripping oil.

4. Remove hose and fitting from “P” port (A).

Picture Note: Valve shown removed for illustration purposes only.

6. Clean screen with solvent or mineral spirits.