Service Cutting Units

Avoid Injury From Contacting Blades

Removing and Installing Cutting Units

NOTE: When removing and installing cutting units be sure the units are installed and connected correctly.

Removing Cutting Units

1. Park the vehicle safely. (See Park Safely in the SAFETY section.)

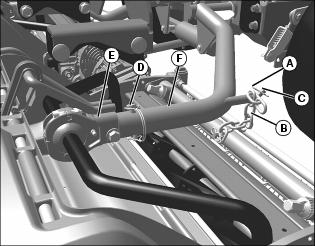

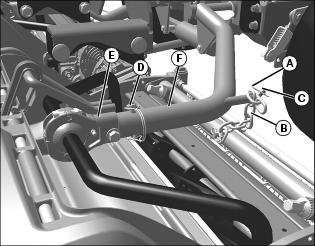

NOTE: Identify which chain link is installed to the lift arm so lift chain can be installed correctly.

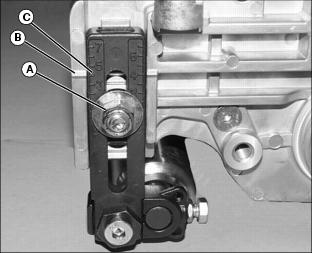

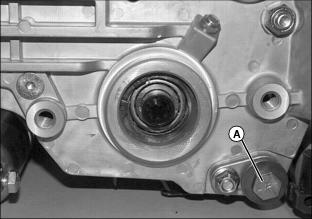

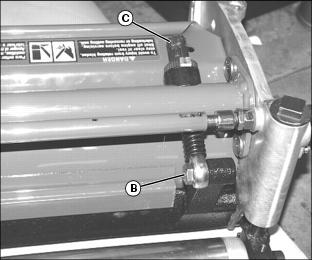

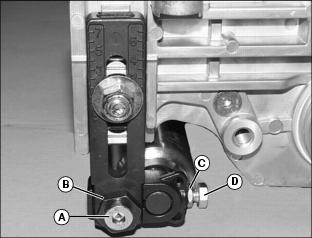

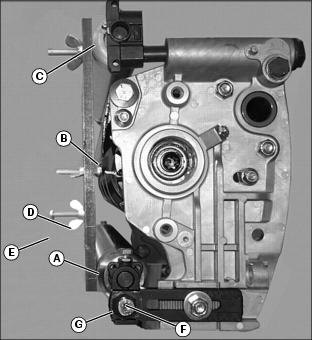

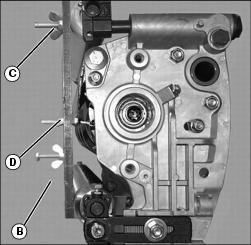

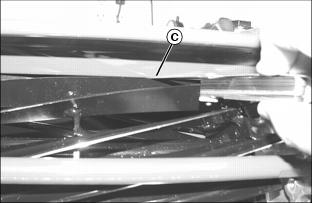

2. Remove spring locking pin (A) and flat washer, and disconnect lift chain (B) from lift arm (C) pin.

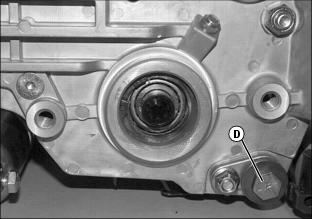

3. Remove quick-lock pin (D), and roll unit away, disconnecting yoke (E) from lift arm (F).

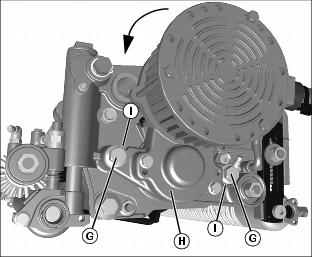

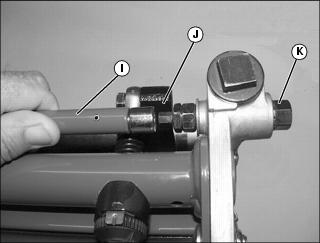

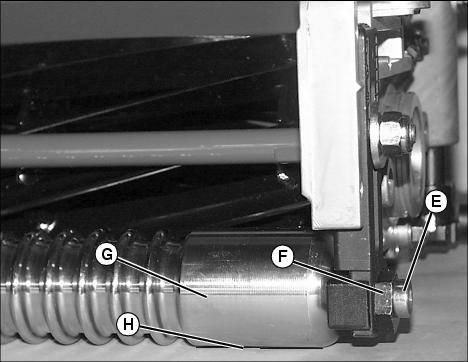

4. Loosen two bolts (G), and rotate and remove hydraulic motor (H) from housing slots (I).

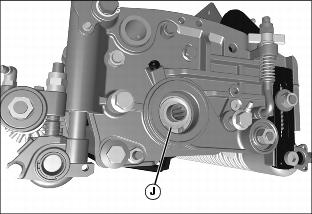

5. Inspect inside of reel bearing housing (J) for grease. Add John Deere Special Purpose HD Cornhead Grease to housing if additional lubrication is needed.

6. Repeat procedure for other cutting units if necessary.

Installing Cutting Units

NOTE: Center cutting unit has the upstop bracket. Right front cutting unit has the steering limiter bracket.

1. Install hydraulic motor (H) onto the reel bearing housing.

• Align splined reel coupling with splined motor drive shaft.

• Align locking assembly hardware with reel bearing housing slots (I).

NOTE: Yoke with steering limiter bracket must be installed to the right front lift arm.

2. Install yoke (E) to lift arm (F).

3. Align yoke pin and lift arm mounting holes.

4. Fasten cutting reel in position with quick-lock pin (D).

NOTE: The lift chain can be installed to different links to adjust cutting unit lift height.

5. Install lift chain (B) onto lift arm pin (C). Make sure chain is not kinked.

6. Install flat washer and spring locking pin (A).

7. Repeat procedure for other cutting units if necessary.

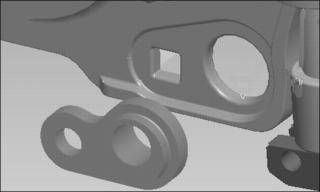

Removing Cutting Unit Yokes

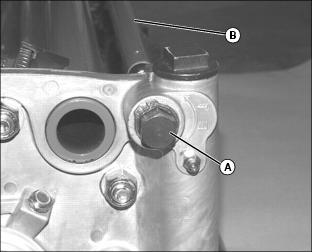

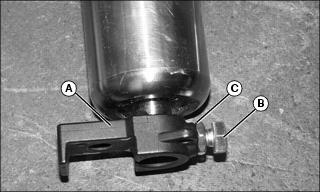

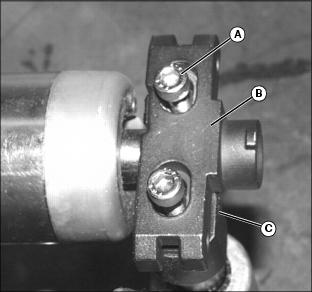

1. Remove hex head bolt (A) from each end of cutting unit yoke.

2. Remove rod (B) and yoke (C).

3. Install in reverse order of removal.

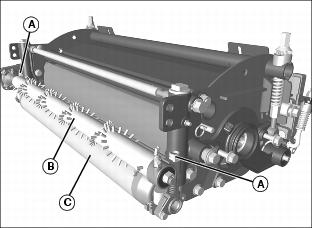

Adjusting Bedknife to Reel (QA-5 Cutting Unit)

IMPORTANT: Avoid damage! Adjust bed knife-to-reel by lowering and raising the bed knife evenly. Do not adjust more than one flat on the adjuster nut at a time, alternating side to side. |

1. Remove cutting unit from machine.

NOTE: If removing unit from machine stand upright on workbench.

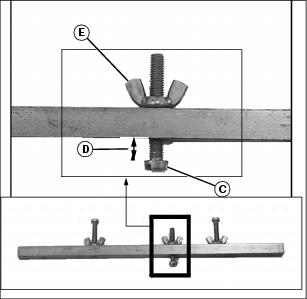

2. Turn bed knife tower adjuster (A) on both sides of cutting unit counterclockwise until bed knife (B) is tight against cutting unit(C).

3. Slowly tighten tower adjuster (A) clockwise, alternating from side to side until bed knife begins to pull away from the cutting reel. Cutting reel should rotate freely.

NOTE: Make sure that the final adjustment to the bed knife is pulling the bed knife away from the cutting reel.

4. Alternately turn adjusters (A) no more than one flat at a time until bed knife (B) to reel (C) clearance (D) measures 0.025 mm to 0.050 mm (0.001 in. to 0.002 in.).

5. Check the bed knife-to-reel clearance (D). Adjust again if necessary.

Adjusting Height Of Cut Range (QA-5 Cutting Unit)

Adjust front roller brackets for the height of cut (HOC) range desired.

1. Select height-of-cut (HOC) adjustment range by adjusting the position of both front roller brackets.

2. Loosen nut (A) on each roller bracket.

3. Alignment of roller bracket (C) and cutting unit frame (B) adjustment holes will determine HOC adjustment range.

• Refer to chart for desired setting.

Adjusting Height of Cut (QA-5 Cutting Units)

NOTE: Use only electric or cordless drill to adjust height of cut. Do not use any type of pneumatic drill or impact wrench.

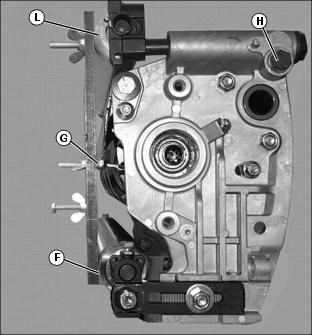

2. Locate the height of cut adjuster (A) on top rear of reel side casting (either side).

3. Turn the height of cut adjustment (A) to decrease or increase height of cut.

NOTE: Adjusters are connected with cross shaft (B) so turning one side simultaneously turns the other.

4. On the height-of-cut (HOC) gauge bar, set center adjustment bolt head (C) at the desired height of cut (D). Lock wing nut (E).

NOTE: Effective HOC could be less then bench setting, based on turf and soil conditions and front roller option.

5. Rest HOC gauge bar against front roller (F) approximately 51 mm (2 in.) from either end of the bed knife. Set the inside of the bolt head (G) against the edge of the bed knife.

NOTE: bottom of screw head on gauge bar should be engadged with cutting edge of bedknife.

6. Turn adjuster (H) until the rear roller (L) contacts the HOC gauge bar. Repeat for the other side of the cutting reel.

7. Check HOC adjustment setting from side to side and adjust if necessary.

8. If side to side HOC adjustment is necessary, pull against spring tension on cross shaft (I) to disconnect it from hex coupling (J). Remove the cross shaft.

9. Turn adjuster (K) until side to side HOC is equal, and then reinstall cross shaft.

Removing and Installing Bedbar (QA-5 cutting Units)

Removing Bedbar

1. Remove the cutting unit from machine.

2. Position cutting unit with the bottom side down on a flat surface or workbench.

3. Increase clearance of bedknife and reel on both sides of cutting unit.

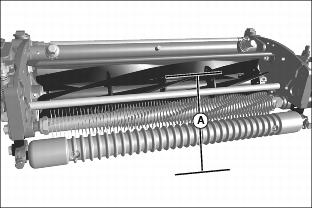

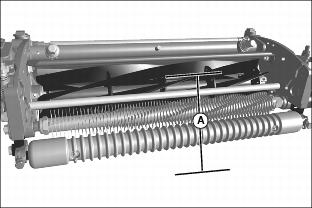

• Turn hex head bolt (A) clockwise until spring (B) is completely compressed. Repeat on opposite side.

4. Remove bolt (C) on each side.

5. Remove bolt (D) from each end of cutting unit, and remove bedbar(E).

6. Inspect bed knife for wear or damage. Replace bed knife, if necessary. (See Replacing Bed Knife in this section.)

7. If original bed knife is to be used again, grind the bed knife. (See Grinding Reel and Bed Knife in this section.)

Installing Bedbar

1. Slide bedbar and into position within cutting unit and secure with bolt (A) on each side. Tighten hardware to 55 N•m (40 lb-ft).

2. Position cutting unit with bottom side down on flat surface or workbench.

3. Install bolt (B) through eyebolt into bedbar.

5. Adjust front roller parallel to bedknife.

8. Check height-of-cut and adjust as necessary.

Replacing Bed Knife (QA-5 cutting Units)

Removing Bed Knife

1. Remove the cutting unit from machine.

2. Position cutting unit with the bottom side down on a flat surface or workbench.

3. Increase clearance of bedknife and reel on both sides of cutting unit.

• Turn hex head bolt (A) clockwise until spring (B) is completely compressed. Repeat on opposite side

4. Rotate cutting unit and position with bottom side up on flat surface or workbench as shown.

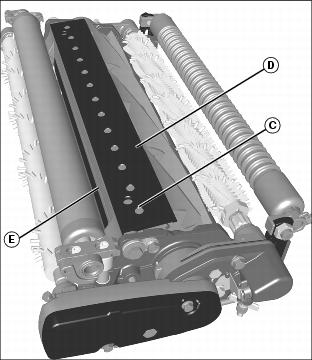

5. Remove and discard thirteen screws (C) attaching bed knife (D) to assembly support (E). Discard bed knife.

6. If original bed knife is to be used again, grind the bed knife. (See Grinding the Bed Knife in this section.)

Installing Bed Knife

NOTE: Remove debris, corrosion, and rust from bottom surface of bed knife support.

1. Install bed knife using new screws. Alternate tightening by starting with center screws and working out to the ends. Tighten screws to 7 N•m (62 lb-in).

2. If installing a used bed knife, grind the bed knife. (See Grinding the Bed Knife in this section.)

3. Adjust front roller parallel to bedknife.

7. Check height-of-cut and adjust as necessary.

Removing and Installing Front Roller (QA-5 Cutting Unit)

Removing Front Roller

1. Remove cutting unit from machine.

2. Position cutting unit upright on a flat surface or workbench.

3. Remove hex head capscrew (A), and eccentric adjuster (B) on both sides of roller.

4. Loosen locknut (C) and loosen capscrew (D) to remove roller bracket from shaft.

Installing Front Roller

NOTE: Roller brackets are offset. For standard use, the bracket should be installed to the roller with the offset to the rear of the base cutting unit to allow close proximity of front roller to rear roller. If (GTC or FTC) is being installed, offset should be to the front to allow the (GTC or FTC) to be installed behind the front roller.

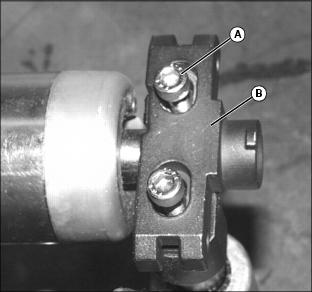

1. Install roller brackets (A) onto each bearing spindle shaft end.

2. Install set screws (B) and locknuts (C) loosely. Do not tighten.

NOTE: Make sure the roller bracket set screw locations are not aligned with the holes in each bearing spindle shaft end. Set screws must engage the bearing spindle shaft at each end.

3. Install roller with eccentric adjuster and capscrew on each side. Center front roller. Tighten set screws (B) and jam nuts (C) on both roller brackets.

4. Tighten roller bracket attaching hardware.

5. Adjust front roller for parallelism.

Adjusting Front Roller Parallel with Bed Knife (QA-5 Cutting Unit)

NOTE: Use of a bench plate or a two or three bolt height-of-cut gauge bar is recommended when adjusting front roller parallel with the bed knife.

Always adjust bed knife-to-reel before adjusting front roller for parallelism.

Always make parallelism adjustment after adjusting front roller height of cut range.

Parallelism Adjustment with Bench Plate

1. Position cutting unit upright on flat surface or workbench.

2. Set bench plate on a level surface. Set cutting unit on top of bench plate (A). Bed knife (B) must rest firmly against plate stop (C) with cutting reel blade (D) on top of plate stop.

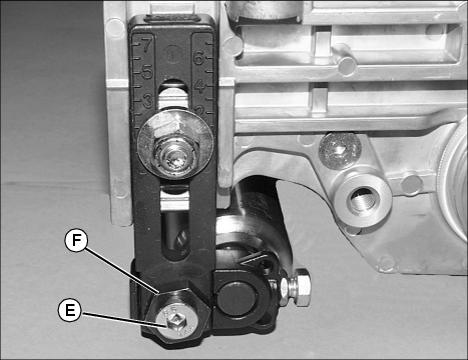

3. Loosen hex bolt (E) on one of the roller brackets.

4. Rotate eccentric adjuster (F) until the front roller (G) sits flat and parallel with the bench plate. Gap (H) should not exceed 0.050 mm (0.002 in.) maximum.

5. Hold roller eccentric adjuster (F) and tighten socket head capscrew (E).

Parallelism Adjustment with HOC Gauge Bar

1. Position cutting unit upright on flat surface or workbench.

2. Rest HOC gauge bar against front roller (A) approximately 51 mm (2 in.) from the end of the bed knife. Set the inside of the bolt head (B) against the edge of the bed knife.

3. Hold end of gauge bar against the bottom of front roller (C).

4. Loosen wing nut (D). Turn lower gauge screw (E) clockwise until top of screw makes contact with flat edge of bed knife.

6. Adjust position of front roller:

• Loosen socket head capscrew (F) and rotate eccentric adjuster (G) until top of lower gauge screw (E) makes contact with the bed knife.

7. Repeat procedure for opposite side.

Removing and Installing Rear Roller (QA-5 Cutting Unit)

Removing Rear Roller

1. Remove cutting unit from machine.

2. Position cutting unit with bottom side up on a flat surface or workbench.

3. Remove capscrews (A) and saddle (B) on each side of roller assembly. Remove roller from each height-of-cut (HOC) bracket (C).

Installing Rear Roller

1. Install roller shaft into each height-of-cut (HOC) bracket.

2. Install saddle (B) and capscrews (A) on each side.

3. Center roller between saddles.

Adjusting Bedknife and Bedbar Position for Worn Reel (QA5)

NOTE: When the reel diameter is reduced to about 4.8 in. (122mm) flipping the eccentric will increase the useful life of the reel.

1. Remove the cutting unit from machine.

2. Position cutting unit with the bottom side down on a flat surface or workbench.

3. Increase clearnce of bedknife and reel on both sides of cutting unit.

• Turn hex head bolt (A) clockwise until spring (B) is completely compressed. Repeat on opposite side

4. Remove hardware on eccentric (A).

6. Flip eccentric 180 degrees as shown.

7. Insert eccentric back into cutting unit.

8. Re-install and tighten hardware.

10. Adjust front roller parallel to bedknife.

13. Check height-of-cut and adjust as necessary.

Adjusting (Optional) Rear Roller Power Brush (QA-7 Cutting Unit)

NOTE: The brush bristles should just barely clear the full length of the roller. The gap between the brush bristle tips and the roller should be approximately 1 mm (1/32 in.).

1. Loosen or tighten locknuts (A), evenly on both sides to adjust the roller brush (B) bristle tips approximately 1 mm (1/32 in.) away from roller (C).

Adjusting Greens Turf Conditioner (GTC) for (QA-5 cutting Unit)

NOTE: Height Of Cut must be adjusted prior to adjusting the Greens and Turf Conditioner.

1. Rotate GTC adjuster wing nut (A).

2. Position cutting unit to make height of cut adjustment.

3. Set GTC adjustment screw (B) on the gauge bar to the desired operating height.

• Adjustment screw (C) may need to be loosened so that the gauge bar can rest on both the front and rear rollers.

4. Place preset gauge bar on cutting unit. Hook height of cut screw (D) on bed knife. The ends should rest firmly on the front and rear rollers.

5. Loosen adjuster locknut (E) on both ends of the cutting unit.

6. Turn wing nut (A) to raise or lower GTC roll. Alternate from end to end until the teeth touch the screw on the gauge bar. Tighten adjuster locknuts (E).

8. Engage GTC clutch by turning wing nut (F), and then turn off.

9. Rotate GTC adjuster wing nut (A) to disengage GTC adjuster stops.

10. Check and tightem GTC collet every 200 hours.

Adjusting Cutting Unit Float Range

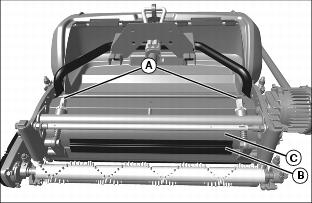

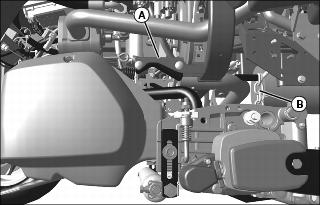

Picture Note: Rear cutting unit upstop (A) and chain (B).

Picture Note: Front cutting unit and upstop (C).

The front cutting unit lift chains (D) can be adjusted if a different cutting unit lift height is desired.

• For initial set up for the front cutting units, attach the seventh chain link to each cutting unit lift arm pin (E). Most normal mowing applications will use the seven chain link set up.

• For applications with level greens and wanting more ground clearance for cutting unit transport, use a six chain link or less set up on the front cutting units. This set up will restrict float on greens with extreme undulations and contours.

• For applications with extreme undulations and contours on greens, use a eight or nine chain link set up on the front cutting units.Cutting unit ground clearance will be limited for transport.

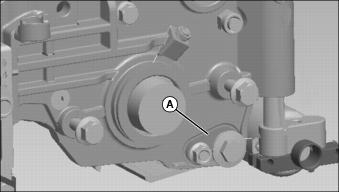

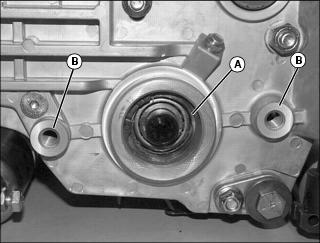

Mounting Motor and Gear Case to Cutting Unit

1. Fill housing cavity (A) with John Deere Cutting Unit Grease or NLGI Grade 0 Grease.

2. Set electric motor and gear case (2500E Hybrid) or hydraulic motor (2500B) in place. Rotate until attaching bolts can be started in reel housing holes (B).

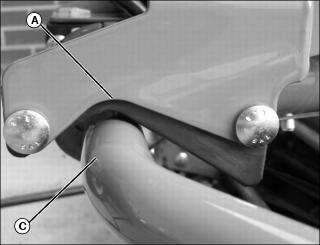

Adjusting Cutting Unit Shield (QA5)

NOTE: Keeping the shield close to the cutting blades improves the performance of the grass catcher in most conditions.

1. Loosen two bolts (A) and locknuts on each side of cutting unit.

2. Raise or lower shield (B) to desired position.

• Maintain an approximate 1.5 mm (0.06 in.) clearance (C) between the bottom of the shield and the top of the cutting blades.

Adjusting Reel Speed

IMPORTANT: Avoid damage! Operating the reels at a high speed can cause excessive bed knife and reel wear. Operate the reels at the appropriate reel speeds. |

1. Park machine safely. (See Park Safely in the SAFETY section.)

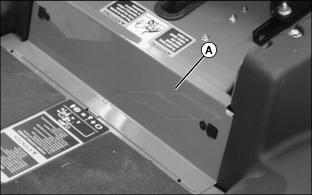

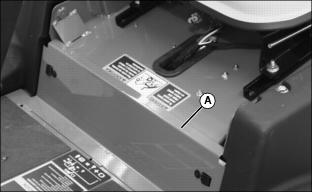

2. Open service access panel (A) below operator seat platform.

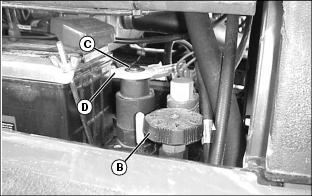

Picture Note: 2500B Model Shown

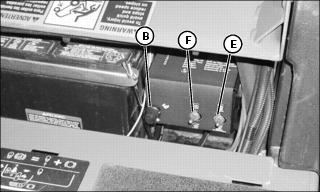

Picture Note: 2500E Hybrid Model Shown

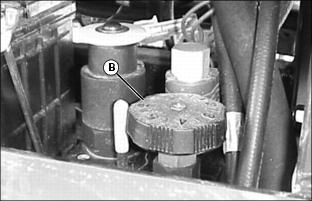

3. Locate reel speed control knob (B).

NOTE: Reel speed can be adjusted depending on the type of application for the greensmower, which type of cutting units are used, and grass height and conditions.

It may be appropriate to reduce reel speed when cutting taller grass to prevent grass from being blown over and not being cut. Faster reel speeds with dry grass may cause grass clippings to be thrown over the grass catcher.

• For mowing greens, set the speed control knob (B) to the highest setting (fully clockwise) for best cutting performance in most conditions.

• For mowing approaches and fairways, reel speed may be reduced by turning the speed control knob counterclockwise.

5. Close service access panel (A).

Check and Adjust Lift Arm Stops

NOTE: Lift arm stop adjustment must be performed at initial set-up and when changing tire sizes.

Check Adjustment

1. Turn key switch to the RUN position.

2. Push raise-lower lever FORWARD to relieve hydraulic pressure in the front and center lift arm cylinders.

3. Push down front and center lift arms.

4. Turn key switch to the STOP position.

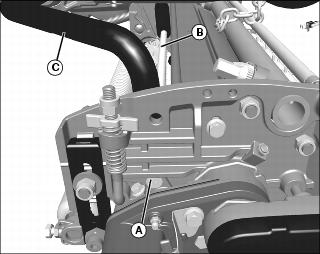

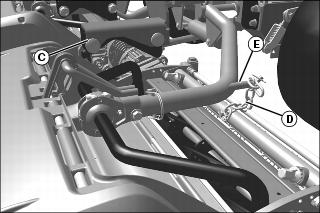

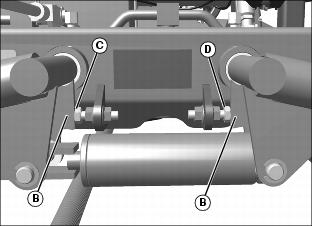

5. Measure distance (A) between the center of each yoke ball joint and the ground.

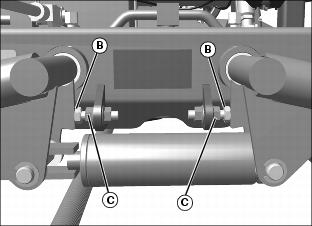

• All three yoke ball joints should be approximately 225 mm (8-7/8 in.) above the ground with the lift arm down stop plates (B) contacting the down stop bolts (C).

Adjust Lift Arm Stops

1. Measure distance (A) between the center of each yoke ball joint and the ground.

Picture Note: Center cutting unit lift arm down stop plate contacting the down stop bolt.

Picture Note: Front cutting unit lift arm down stop plates contacting the down stop bolts.

2. Loosen down stop bolt jam nuts (C).

3. Adjust the down stop bolts (B) as needed until all three yoke ball joints are 220-230 mm (8.7-9.1 in.) above the ground.

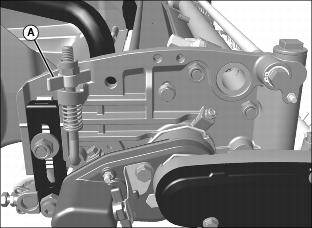

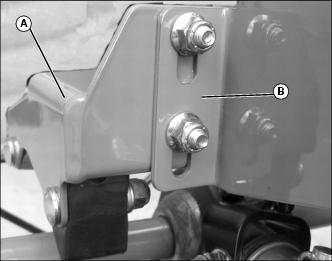

Adjusting Front Upstops

IMPORTANT: Avoid damage! Yoke arms must not hit upstops when cutting units are raised because impact can damage the cutting units, support brackets, or foot platform. |

1. Lower cutting units to the ground

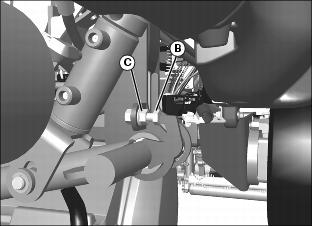

2. Adjust front upstops (A) to the top of the slots in support brackets (B).

3. Raise cutting units to full lift height.

4. Adjust each upstop so there is 1-3 mm (0.04-0.12 in) of clearance between the yokes arms (C) and the bottom of the upstops (A) when the cutting units are in the fully raised position.

Grinding Reel and Bed Knife

Reel and Bed Knife Relationship

Reel mowers are precision machines requiring daily maintenance to maintain the well-groomed appearance of turfgrass. The scissor-like shearing action, that only a reel mower is capable of achieving, is only possible if the reel and bed knife are sharp and the reel-to-bed knife clearance is maintained.

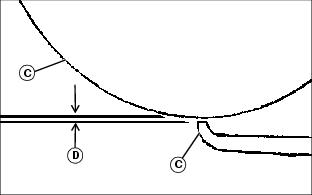

Close examination of the reel-to-bed knife relationship reveals two square edges passing one another with approximately 0.051 mm (0.002 in.) clearance. There are several reasons why this clearance is necessary.

• When the reel is allowed to contact the bed knife, the square (sharp) edges of the reel and bed knife will roll over, becoming dull.

• Contact between the reel and bed knife generates heat. Heat generated through this contact will distort the shape of the bed knife. Distortion causes the bed knife to draw closer to the reel, resulting in more rollover of the cutting surfaces and more heat generated in the bed knife.

• Drag produced by an improperly adjusted cutting unit may result in an unacceptable clip ratio, undue strain on drive mechanisms and premature wear of the cutting unit.

Reasons for Grinding

• To restore the cylindrical shape of a reel that has become cone-shaped due to improper adjustment of the reel-to-bed knife clearance or worn reel bearings.

• To restore the edge when the grass is not being cut across the entire length of the bed knife, evidenced by streaks of grass left after the mower has passed. Usually the result of nicked blades caused by hitting foreign objects in the grass.

• To restore the edge when the lack of frequent backlapping allowed the edge to be rounded beyond the capability of the backlapping procedure to restore the edge.

• To restore the edge when the reel-to-bed knife clearance has been improperly adjusted (reel contacting bed knife).

Cutting action begins as the bed knife positions the grass to be cut at the cutting edge. The reel then pulls the grass toward the bed knife where it is sheared by the cutting edges as they pass one another.

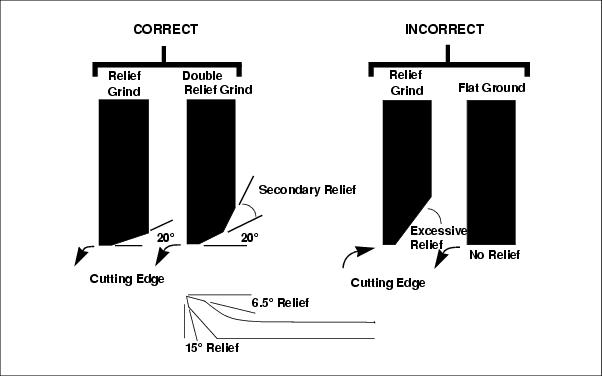

In order for the grass to be cut at the proper height, it must contact the bed knife at the cutting edge. This is accomplished by grinding a 15° relief angle on the front face of the bed knife. Without a relief angle, the blade of grass will contact the lower edge of the bed knife and be bent over at too much of an angle prior to being cut. In the case of mowing greens, where very small cuts are being taken, the reel may not capture the grass at all, and no grass will be cut.

Although some spin grinding machine manufacturers say backlapping is not necessary, John Deere recommends backlapping after spin grinding to remove burrs and rough edges left from the spin grinding procedure. Backlapping produces a honed edge that will cut the grass evenly and leave the tops of the grass with clean, straight edges.

It is important to note, dull cutting edges will tear rather than shear the grass drawn into the bed knife. This will shock the grass plant and retard its growth.

Grinding the Bed Knife

NOTE: Bed knife and support assembly must be ground as a complete unit.

1. When grinding the bed knife, it is important to have a 6.5° relief angle on the top surface (A) and a 15° relief angle on the front surface (B).

2. Put entire bed knife support and bed knife in a suitable grinder and grind until material is consistently removed from the entire length of the top and front surfaces of the bed knife.

Grinding the Reel

John Deere recommends relief grinding the reels after spin grinding for these reasons:

• Reduced blade contact area results in less friction, requiring less horsepower to drive the reel and increases fuel efficiency.

• Less time is required to backlap.

• Reduces pulling and tearing of the grass as the unit gets dull by use.

• Provides an area for backlapping compound to be trapped to more effectively backlap reels.

• Relief grinding removes metal from the trailing edge of the blade, forming an angle (relief angle) to reduce the contact area of the cutting edges.

• Because of the relief grind it is possible, with backlapping, to true a reel (make it round) if a blade is 0.025-0.051 mm (0.001-0.002 in.) too high.

Backlapping Cutting Units

The backlapping procedure is used to sharpen the cutting edges when grinding is not necessary. See GRINDING REEL AND BED KNIFE in this section to determine if grinding is necessary.

Backlapping, when compared to grinding, removes a very small amount of metal, requires less time and will effect a smooth, clean cut.

The backlapping procedure is accomplished by spinning the reel backward while applying special abrasive compounds to the reel. Usually, course compounds are used initially, followed by a finer abrasive for final honing. Recommended grits for fairways and roughs are 60, 80, and 120. Reel lapping compounds should not be toxic, oily or greasy.

The cutting unit should be inspected, backlapped, adjusted and checked daily for a uniform cut along the complete length of the bed knife. It is important that the adjustment allows the reel to turn freely without dragging against the bed knife. Metal-to-metal contact will generate heat, causing the reel to expand and intensifying the dragging that produces more heat. This cycle will quickly "shut down" the mower.

NOTE: To help maintain sharp edges required on cutting reels, bed knife-to-reel clearance should be checked before the backlapping function begins. The bed knife must be adjusted properly to ensure light, even contact over the length of the cutting blades.

Cutting reels are all backlapped at the same time.

1. Check bed knife-to-reel clearance on all three cutting reels. Adjust if necessary.

3. Move mow-transport lever to the TRANSPORT position.

5. Lower cutting units to the ground.

NOTE: Operator must be off the seat for the backlapping valve to function.

7. Open service access panel (A) below operator seat platform.

8. Locate backlapping control to the left of the battery.

• Position throttle lever between mid-range and SLOW idle.

Picture Note: 2500B Model Shown

Picture Note: 2500E Hybrid Model Shown

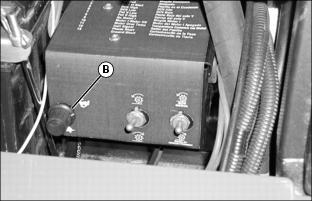

• Adjust reel speed control knob (B) fully counterclockwise.

2500B

NOTE: Forward-reverse control knob must be pulled up completely past first detent for the backlapping valve to function properly.

• Press in on the release button (C) at the center of the forward-reverse knob (D) and pull the knob out until it locks into the reverse position.

2500E Hybrid

• Move mow-backlap switch (E) to BACKLAP position.

• Move forward-reverse switch (F) to REVERSE position.

12. Move the mow-transport lever to MOW position.

13. Activate raise-lower lever.

• Move and hold lever forward.

• When cutting reels begin turning in REVERSE, release lever.

NOTE: Adjust reel speed so that reel sharpening compound is not thrown off during the backlapping procedure.

14. Increase reel speed slightly, but not so fast that backlapping compound is thrown off.

15. Using a long-handled brush, carefully apply reel sharpening compound, uniformly, from one end of the cutting reel to the other. Repeat application in opposite direction. Allow cutting reel to continue running backwards until reel is quiet.

16. Periodically disengage cutting units by moving the mow-transport lever to the TRANSPORT position and turn key switch to the STOP position. Visually check blade appearance.

NOTE: 2500B - Forward-reverse control knob must be pushed down to restart engine.

2500E Hybrid- Mow backlap switch must be moved to MOW to restart engine.

• Check for uniform clearance across entire bed knife. If clearance is not uniform, repeat backlapping procedure until clearance is uniform across entire bed knife.

Repeat process until the bedknife and reels are returned to a sharp condition.

IMPORTANT: Avoid damage! Do not operate cutting reels in the forward direction until reel sharpening compound is washed from the unit. Unless properly washed, the reels can be dulled by the compound. |

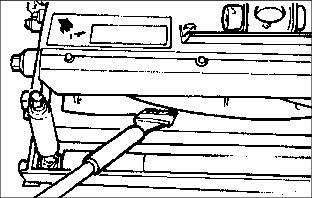

17. Use water to thoroughly wash off all reel sharpening compound while cutting reels are turning in reverse.

18. Adjust reel-to-bed knife clearance.

19. Move mow-transport lever to the TRANSPORT position.