Operating

Daily Operating Checklist

Avoid Damage to Plastic and Painted Surfaces

• Do not wipe plastic parts unless rinsed first.

• Insect repellent spray may damage plastic and painted surfaces. Do not spray insect repellent near machine.

• Be careful not to spill fuel on machine. Fuel may damage surface. Wipe up spilled fuel immediately.

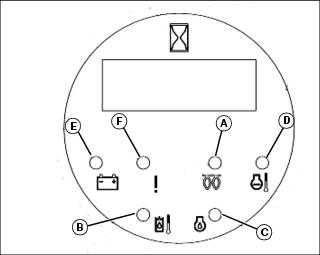

UsIng Indicator Lights

• Engine Preheat (A) (Diesel Models) will glow when key switch is turned to the run position. After approximately three seconds the light will go out.

• Hydraulic Oil Temperature Indicator (B) will glow when hydraulic oil temperature is high. Stop all hydraulic functions immediately. Let hydraulic oil temperature cool by allowing engine to idle under a no-load situation. This keeps the oil flowing through the oil cooler and cools the oil. Check oil level and make sure oil cooler coils are clean. Continued operation may cause higher temperatures, resulting in damage.

• Engine OIl Pressure Indicator (C) will glow when engine oil pressure is low. If lamp glows when engine is running, stop engine immediately. See your John Deere distributor.

• Engine Coolant Temperature Indicator (D) will glow if engine temperature becomes excessive. Stop engine and determine cause.

• Battery Discharge Indicator (E) will glow when alternator is not producing adequate current. Stop engine and determine cause.

• Reel Controller Diagnostic Light (F) will flash when a problem occurs with the electric-powered cutting units found on the 2500E Hybrid models. The number of times it flashes indicates an error code listed on the reel controller diagnostic label.

• Hydraulic Leak Detection System Indicator (optional - not shown) will glow and an alarm will sound momentarily when the key switch is turned on. If a hydraulic leak is detected, the light will glow and the alarm will sound until the key switch is turned off.

Using Operating Controls

Using Key Switch

NOTE: To help prevent engine backfiring, the engine will continue to run approximately two seconds after key switch is turned to the stop position. After engine has stopped, an approximate two-second delay will prevent the engine from immediately being restarted.

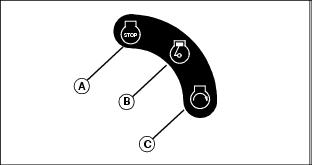

Key Switch Positions

• Stop position (A) - shut engine off.

• Run position (B) - the engine oil pressure indicator light and battery indicator light should come on. (Diesel Models) Glow plug indicator light will illuminate for approximately three seconds and then go out. Engine is now ready to start.

• Start position (C) - starter should engage and crank the engine. After engine starts release the key to the run position. All indicator lights should go out.

Starting the Engine - Gas Model

NOTE: The greensmower has an ignition interlock switch. The engine will not start unless the park brake is locked and the mow-transport lever is in the transport position.

3. Move mow-transport lever to transport position.

4. Move throttle lever to the half-speed position.

• Cold engine: Pull knob out to the choke position.

• Warm/hot engine: If necessary, pull knob out to the choke position.

6. Turn the key switch to the run position. The battery, engine oil pressure and leak detector (if equipped) indicator lights should come on.

7. Turn the key switch to the start position. The hydraulic oil temperature, engine oil pressure, battery, engine coolant temperature and leak detector (if equipped) indicator lights should all come on.

8. When engine starts, release key to the run position.

NOTE: If any indicator lights remain lit after engine has started, stop engine immediately. Diagnose and correct the problem.

9. After the engine starts, all indicator lights should go out.

IMPORTANT: Avoid damage! Unnecessary engine idling may cause engine damage. Excessive idling can cause engine overheating, carbon build-up, and poor performance. |

10. Let engine run at half speed for a couple of minutes to warm up before operating machine.

11. Push in choke knob as engine warms up to keep engine running smoothly.

Glow Plug (Diesel Models)

NOTE: Glow plugs preheat the combustion chamber for better starting performance.

1. Turn key switch to the run position.

• The glow plug indicator light should turn on.

• The indicator light should go off approximately three seconds after the key switch is turned to the run position.

2. Turn the key switch to the START position to start the engine.

Starting the Engine - Diesel Model

NOTE: The greensmower has an ignition interlock switch. The engine will not start unless the park brake is locked and the mow-transport lever is in the transport position.

4. Move mow-transport lever to transport position.

5. Move throttle lever to half-speed position.

6. Turn key switch to run position. The battery, engine oil pressure and leak detector (if equipped) indicators will light.

7. Glow plug preheat indicator will light.

• After approximately three seconds, indicator light will go out.

8. Turn key switch to start position. The hydraulic oil temperature, engine oil pressure, battery, engine coolant temperature and leak detector (if equipped) indicators will light.

NOTE: If any indicator remains lit after engine has started, stop engine immediately. Diagnose and correct the problem.

9. Release key switch to run position when engine starts. All indicator lights should go out.

IMPORTANT: Avoid damage! Unnecessary engine idling may cause engine damage. Excessive idling can cause engine overheating, carbon build-up, and poor performance. |

10. Let engine run at half speed for a couple of minutes to warm up before operating machine.

Stopping the Engine

1. Move throttle lever to SLOW position. Allow engine to idle before stopping.

2. Move Mow/Transport lever to the TRANSPORT position.

3. Push raise/lower lever forward to lower cutting reels. Wait until the center cutting reel is fully lowered.

NOTE: To help prevent engine backfiring, the engine will continue to run approximately two seconds after key switch is turned to the STOP position. After engine has stopped, an approximate two second delay will prevent the engine from immediately being restarted.

5. Turn key switch to STOP position (D).

Using Hydrostatic Transmission

2. Move mow-transport lever to the transport position.

3. Pull raise-lower lever rearward to raise cutting units.

4. Move throttle lever forward to the fast position.

To Travel in Forward or Reverse

NOTE: The travel pedals are pressure sensitive. The farther the pedals are depressed, the faster the greensmower will travel.

1. To travel forward, depress forward travel pedal.

2. Remove foot from pedal to stop mower.

3. To travel in reverse, depress reverse travel pedal.

4. Remove foot from pedal to stop mower.

Using the Mow-Transport Lever

NOTE: When switching from transport to mow the reel controller diagnostic light will turn on for a few seconds then turn off. This is normal and does not indicate a problem.

1. Pull the raise-lower lever rearward to raise cutting units.

IMPORTANT: Avoid damage! Moving the Mow-Transport lever while the travel pedals are in use may cause damage to the Mow-Transport cable. Release the travel pedals before using the Mow-Transport lever. |

2. Move the mow-transport lever to the mow position.

3. Push the raise-lower lever forward to lower cutting units.

• Cutting reels will begin to rotate as the cutting units are lowered.

4. Pull raise-lower lever rearward to raise cutting units.

• Cutting reels will stop rotating as the cutting units are raised.

5. Move the mow-transport lever to the transport position to disengage reel drive for cutting units.

Using the Raise-Lower Lever

1. Push raise-lower lever forward to lower cutting units.

• If the mow-transport lever is in the mow position, the cutting reels will begin to rotate.

• if the mow-transport lever is in the transport position, the cutting units will lower but the reels will not rotate.

2. Pull raise-lower lever rearward to raise cutting units.

• If the mow-transport lever is in the mow position, the cutting reels will stop rotating.

Using the Hour Meter

• The hour meter shows the approximate number of hours the greensmower has run.

• Use the hour meter and Service Interval Chart to determine when the greensmower will need service.

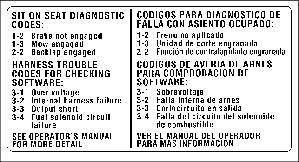

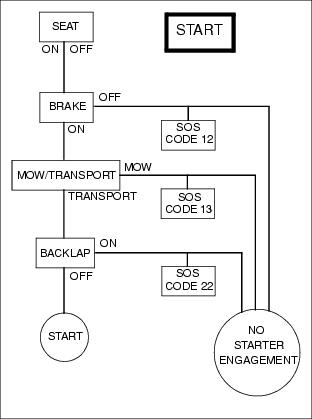

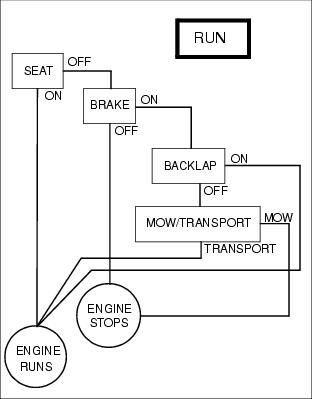

Sit-On Seat Diagnostics

Sit-On-Seat (SOS) diagnostics are provided to help diagnose problems starting the engine.

The following conditions must be met to energize the starter solenoid and engage the starter motor:

• Mow-transport lever in the transport position.

• Key switch in the START position.

If engine does not turn over, hold the key in the START position, the battery discharge light on the warning light-hour meter module will begin to flash a diagnostic code.

NOTE: Sit-On-Seat diagnostic code label is located under console armrest.

• PARK BRAKE diagnostic code: one flash, a short pause and two additional flashes. This code sequence indicates that the park brake switch has not been activated. Lock park brake to start engine.

• BACKLAP SWITCH diagnostic code: two flashes, a short pause and two additional flashes. This code sequence indicates that the backlap valve is in the backlap position. Turn off backlap valve and start engine.

• MOW SWITCH diagnostic code: one flash, a short pause and three additional flashes. This code sequence indicates that the mow switch is activated. Move mow-transport lever to the transport position to start engine.

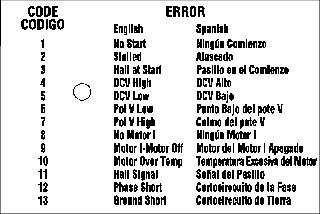

Reel Controller (SOS) Diagnostics

NOTE: When switching from transport to mow the indicator light will come on for a short period. This indicates the 48-Volt system has been activated.

If multiple cutting units shut down the codes will overlap and be more difficult to diagnose.

Reel controller diagnostics are provided to help diagnose problems with the electric powered cutting units found on the 2500E Hybrid models.

When a problem occurs, the reel controller diagnostic light on the warning light-hour meter module will flash. The number of times it flashes indicates an error code listed on the reel controller diagnostic label. Use the error code to help diagnose the problem. (See the Troubleshooting section for more information.)

NOTE: Reel controller diagnostic label is found on the side of the console. (See Adjusting Reel Speed in the Service - Cutting Units section).

Adjusting Seat

NOTE: If needed, use the front set of holes in the seat base to provide the most rearward seat position and increased leg room.

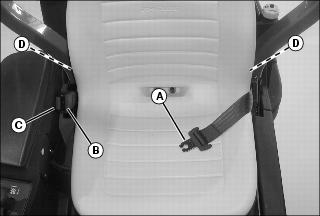

1. Sit on the seat and pull lever (A) to the left.

2. Slide seat forward or backward to desired position.

Using Seat Belt

2. Pull out seat belt buckle (A) and stretch across your lap in one nonstop motion.

3. Insert seat belt buckle into latch (B) until it locks.

4. To release seat belt, press red button (C) until buckle comes out of latch.

5. Tighten seat belt mounting hardware (D) to 34-47 N•m (25-35 ft-lbs).

Adjusting Tilt Steering Wheel

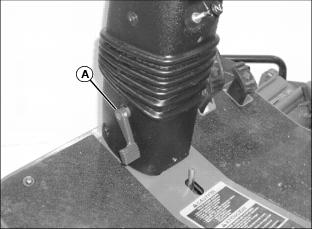

1. Press and hold adjustment pedal (A).

2. Move steering wheel to desirable operating position.

3. Release pedal to lock steering wheel in position.

Testing Safety Systems

The safety systems installed on your machine should be checked before each machine use. Be sure you have read the machine operator manual and are completely familiar with the operation of the machine before performing these safety system checks.

Use the following checkout procedures to check for normal operation of machine.

If there is a malfunction during one of these procedures, do not operate machine. See your authorized dealer for service.

Perform these tests in a clear open area. Keep bystanders away.

Testing Mow-Transport Lever Switch

Test 1

3. Put transmission in NEUTRAL.

4. Move mow-transport lever to the MOW position.

5. Turn key switch to the START position.

Result: Engine must not start. The Sit-On-Seat indicator light should flash. If engine starts, there is a problem with the safety interlock circuit.

NOTE: Move mow-transport lever to the TRANSPORT position and turn the key to the STOP position before starting engine.

Test 2

3. Put transmission in NEUTRAL.

6. Lower cutting units to the ground.

7. Move mow-transport lever to the MOW position.

Result: Engine must stop within two seconds with no rotation of cutting reels. If engine does not stop, there is a problem with the safety interlock circuit.

Testing Raise-Lower Lever Switch

3. Move mow-transport lever to the TRANSPORT position.

6. Put the transmission in neutral.

7. Lower cutting units with the raise-lower lever.

8. Move mow-transport lever to the MOW position.

Result: Cutting reels must not rotate. If reels rotate, there is a problem with the safety interlock circuit.

Testing Seat Switch

Test 1

3. Move mow-transport lever to the TRANSPORT position.

6. Put transmission in neutral.

7. Move mow-transport lever to the MOW position.

8. Push the raise-lower lever forward. Cutting reels should start rotating.

Result: Engine must stop within two seconds and reels should stop rotating. If engine does not stop, there is a problem with the safety interlock circuit.

Test 2

3. Start engine and set at slow idle.

5. Put the transmission in neutral.

6. Move mow-transport lever to the TRANSPORT position.

Result: Engine must stop within two seconds. If engine does not stop, there is a problem with the safety interlock circuit.

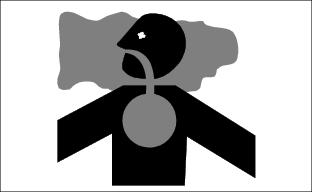

Ignition Interlock Systems

For the starter to engage, the following conditions must be met:

• Operator can be on or off the seat.

• Mow/Transport lever in the TRANSPORTposition.

• Backlap valve in OFF position.

For the engine to run, the following condition must be met:

• Operator must be on the seat or the park brake must be engaged.

If the Mow/Transport lever is in the TRANSPORT position with the park brake not engaged and the operator raises off the seat, the engine will stop.

If the Mow/Transport lever is in the MOW position with the park brake engaged and the operator raises off the seat, the engine will stop.

If the cutting reels are rotating and the operator raises off the seat, the cutting reels and engine will stop.

In order to mow, the following conditions must be met:

• Operator in the operator seat.

• Throttle lever moved to the FAST position.

• Mow/Transport lever in the MOW position.

• Cutting units lowered to the ground.

• Backlap valve in OFF position.

If the operator is mowing and the park brake is depressed, the cutting reels will stop rotating.

If the operator is mowing and engages the backlapping valve while on the operator seat, the cutting reels will stop rotating.

If the operator attempts to backlap the cutting units with the operator seat occupied, the cutting reels will not rotate.

If the operator is backlapping the cutting units with the operator seat not occupied and the park brake is unlocked, the engine will stop.

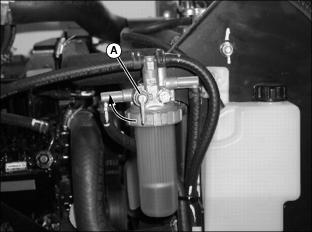

Using Fuel Shut-Off Valve (Diesel Model)

2. Locate fuel filter sediment bowl assembly on left side of engine.

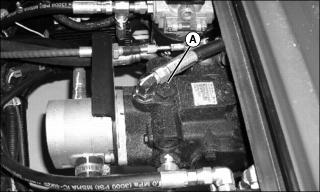

Picture Note: Fuel Shut-off Valve Shown in the Open Position

3. Rotate fuel shut-off valve lever (A) to the “O” (open) position or “C” (closed) position.

“C” (Closed) Position

• When performing any type of engine service.

• During periods of extended storage.

“O” (Open) Position

• Fuel shut-off valve must be in the full open position for proper fuel delivery to the engine.

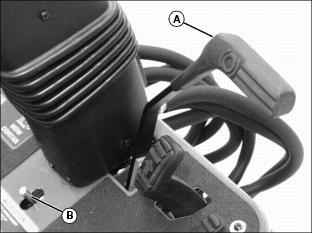

Using Park Brake

Locking the Park Brake

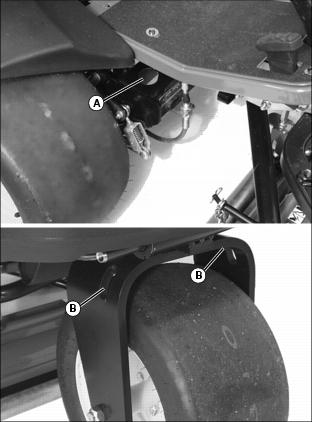

1. Push and hold brake pedal (A) down.

2. Push park brake lock (B) down.

4. Release park brake lock. Brake pedal should stay down and park brake lock should stay locked.

Unlocking the Park Brake

1. Push brake pedal (A) down. Park brake lock (B) should release immediately.

Adjusting Mowing Speed

NOTE: Greensmower is preset at the factory to operate at approximately 7.1 km/h (4.4 mph).

Wheel RPM’s necessary to meet the preset mow speed specification are 178 to 192. Wheel RPM’s have been preset at the factory to assure proper forward mow speed regardless of tire size.

1. Park the vehicle safely. (See Park Safely in the SAFETY section.)

2. Locate mow speed adjustment (A).

3. Move Mow/Transport lever to the MOW position.

NOTE: Preliminary dimension (B) between top of mow speed adjustment and bottom of forward travel pedal linkage is 22 mm (0.87 in.) When mow speed adjustments change, record any dimension (B) changes for future reference.

• Increase dimension (B) for increased mowing speed.

• Decrease dimension (B) for decreased mowing speed.

7. Move Mow/Transport lever to the TRANSPORT position.

8. Measure off 30.5 m (100 ft.)

10. Move Mow/Transport lever to the MOW position.

11. Move throttle lever to the FAST position. Depress FORWARD travel pedal fully.

12. Record the number of seconds it takes to travel the 30.5 m (100 ft.) length.

13. Refer to applicable cutting ratio table to determine ground speed and frequency of cut.

14. Continue adjustment process until desired mowing speed and frequency of cut is achieved.

Cutting Ratios

Emergency Stopping

• Push on park brake pedal (A).

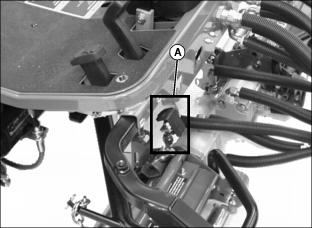

Moving Machine Manually

IMPORTANT: Avoid damage! Transmission damage may occur if the machine is moved incorrectly: • Do not use another vehicle to move unit. |

When movement of machine is required without starting the engine, use the bypass valve.

1. Stop engine and remove key.

3. Lift and secure operator seat in the raised position.

4. Turn bypass valve (A) counterclockwise 90°.

7. Push greensmower to desired location.

8. Turn bypass valve (A) clockwise 90° to the closed position.

Transporting Machine on Trailer

NOTE: Use a heavy-duty trailer designed to carry 909 kg (2000 lb), or a truck box to transport the machine.

2. Secure the cowling to the machine at the front to prevent the hood opening accidentally during transporting

4. Lower the cutting units to the deck.

5. Secure machine to trailer with straps, chains, or cables.

• Attach the tie downs to slots (A) provided on both sides of the operator's station in the main frame and slots (B) on both sides of the rear wheel yoke.

6. Use accessory lights and devices when transporting the machine on a road or highway to provide adequate warning to operators of other vehicles. Check local, state, provincial, or federal laws.