Service Transmission

Transmission Oil

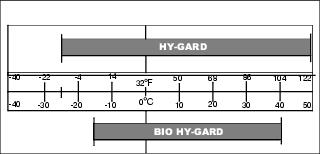

Use oil viscosity based on the expected air temperature range during the period between oil changes.

IMPORTANT: Avoid damage! Only use a quality oil in this transmission. Do not mix any other oils in this transmission. Do not use engine oil or “Type F” (Red) Automatic Transmission Fluid. |

Checking Transmission Oil Level

IMPORTANT: Avoid damage! Hot hydraulic oil will expand and show incorrect oil level. Check oil level: |

1. Park vehicle safely. (See Parking Safely in the Safety section.)

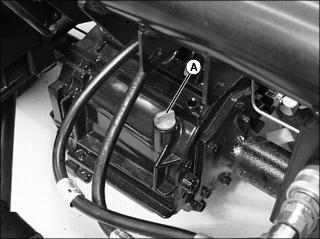

2. Thoroughly clean area around reservoir fill cap/dipstick (A) at rear of machine.

3. Remove fill cap/dipstick and wipe with a clean cloth.

NOTE: DO NOT tighten dipstick. Allow threads to rest on top of transmission housing.

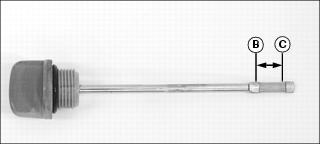

5. Remove fill cap/dipstick. Check oil level on dipstick. Oil level should be between levels (B) and (C) on the dipstick.

• If oil is low, add oil to bring oil level no higher than level (B) on the dipstick.

• If oil is above level (B) on the dipstick, drain to proper level.

Changing Transmission Oil and Filter

1. Raise attachment to service position. (See Using the Lift Cylinder Safety Support in the Safety section.)

2. Park vehicle safely. (See Parking Safely in the Safety section.)

• Allow the engine and transmission to cool.

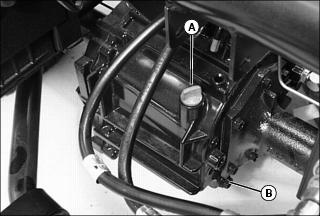

3. Thoroughly clean area around the transmission fill cap/dipstick (A). Remove fill cap/dipstick.

4. Locate drain plug (B) under right side of transmission.

5. Remove drain plug. Allow oil to drain into a drain pan with at least a 10.6 L (2.8 gal) capacity.

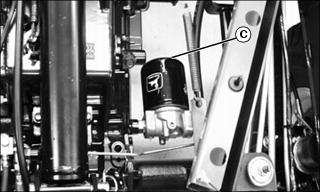

NOTE: If the vehicle is equipped with an auxiliary hydraulic kit, the transmission filter (C) is relocated to the right side of the vehicle.

6. Locate transmission oil filter (C) on the right side of vehicle on the transaxle.

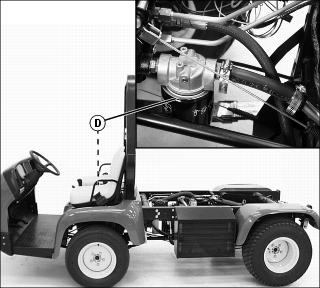

NOTE: If vehicle does not have an auxiliary hydraulic kit installed, the transmission filter (D) is located in the center of vehicle, directly behind control valve.

a. Locate transmission oil filter (D) on standard machine in the center behind control valve.

7. Turn filter counterclockwise to remove. Use a drain pan to catch dripping oil.

• Apply a film of clean oil on gasket of new filter.

• Turn filter clockwise until gasket makes contact with the mounting surface. Tighten 1/2 to 3/4 turn after gasket contact.

9. Clean transmission oil strainer.

10. Install and tighten drain plug, torque to 49 N•m (36 lb-ft).

11. Add approximately 8.5 L (2.25 gal) of oil into fill opening.

NOTE: DO NOT tighten dipstick. Allow threads to rest on top of transmission housing.

12. Install fill cap/dipstick.

13. Remove fill cap/dipstick. Check oil level; add or drain oil to correct level if required.

14. Install fill cap/dipstick.

Clean Transmission Oil Strainer

NOTE: Routinely clean strainer when changing the transmission oil and filter. Strainer should be serviced when the transmission is empty.

1. Change transmission oil and filter.

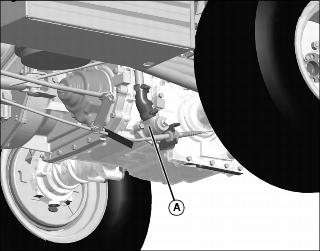

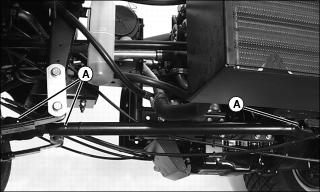

2. Locate strainer housing (A) on the left side of vehicle.

NOTE: Use drain pan to catch dripping oil.

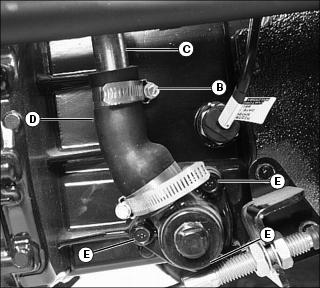

3. Loosen adjustable hose clamp (B).

4. Remove hydraulic line (C) from rubber hose (D).

5. Loosen and remove three hex bolts (E).

6. Remove strainer housing and strainer.

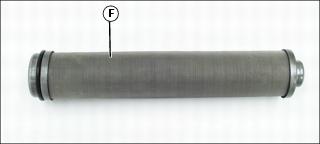

7. Clean strainer (F) with solvent or mineral spirits and allow to dry.

8. Install strainer into the strainer housing.

10. Install and tighten three hex bolts (E).

11. Install rubber hose (D) onto hydraulic line (C).

12. Tighten adjustable hose clamp (B).

Grease

The following greases are preferred:

• John Deere Multi-Purpose SD Polyurea Grease

• John Deere Multi-Purpose HD Lithium Complex Grease

If not using any of the preferred greases, be sure to use a general all-purpose grease with an NLGI grade No.2 rating.

Wet or high speed conditions may require use of a special-use grease. Contact your Servicing dealer for information.

The following lubricant is preferred:

• SUPER LUBE® lubricant.1

Lubricating the Drive Shaft (4WD Models)

1. Park vehicle safely. (See Parking Safely in the Safety section.)

2. Lubricate three grease fittings (A) on the drive shaft with John Deere SD Polyurea grease or an equivalent.