Service Lubrication

Grease

The following greases are preferred:

• John Deere Multi-Purpose SD Polyurea Grease

• John Deere Golf & Turf Cutting Unit Grease

If not using any of the preferred greases, be sure to use a general all-purpose grease with an NLGI grade No.2 rating.

Wet or high speed conditions may require use of a special-use grease. Contact your Servicing dealer for information.

Transmission and Hydraulic Oil

IMPORTANT: Avoid damage! Machine is filled with John Deere HY-GARD™ (J20C) Transmission/Hydraulic Oil at the factory. DO NOT mix oils. DO NOT use type “F” automatic transmission fluid. |

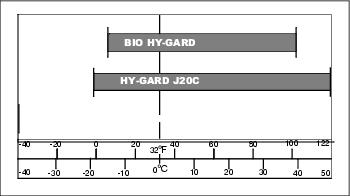

Use oil viscosity based on the expected air temperature range during the period between oil changes.

John Deere J20C HY-GARD Transmission/Hydraulic Oil is recommended.

Use John Deere BIO HY-GARD™ oil when a biodegradable fluid is required.

Biodegradable Oil

Application

When use of a biodegradable lubricant is desired or required, BIO HY-GARD is recommended. BIO HY-GARD may be used under normal mowing conditions.

DO NOT USE biodegradable lubricants in machines for the following operations:

• Any machine used for scalping procedure.

• Any verticut operation in temperatures exceeding 32?C (90?F).

• Mixing of biodegradable oil and mineral oil will reduce the biodegradability of the lubricant in the machine. Mixing of HY-GARD and BIO HY-GARD will not result in performance deterioration.

Cold Weather Operation

Precautions should be taken if BIO HY-GARD containers or equipment are stored for long periods of time in extremely cold temperatures. Freezing should be expected if BIO HY-GARD is subjected to the following temperatures:

• Stored for six months at -18? to -23?C (-1? to -10?F)

• Stored for seven days at -23? to -26?C (-10? to -15?F)

• Stored for three days at -26? to -29?C (-15? to -20?F)

• Stored for two days at -29? to -34?C (-20? to -30?F)

• Stored for one day at -34?C (-30?F) and below.

IMPORTANT: Avoid damage! Equipment should not be started or any operation attempted until BIO HY-GARD™ has reached a safe operating viscosity. |

If freezing of BIO HY-GARD is suspected, the container or equipment MUST be warmed to at least 0?C (32?F) and maintained for 24-48 hours to ensure the fluid has reached a safe operating viscosity.

Converting From HY-GARD to BIO HY-GARD

Systems being converted from HY-GARD to BIO HY-GARD should follow the procedure listed below to obtain maximum lubricant biodegradability.

1. Park machine on a level surface.

2. Stop engine and set park brake.

4. Fill gearcase with BIO HY-GARD to appropriate level.

5. Start engine and bring to medium idle.

6. Cycle cutting reel several times.

7. Stop engine and check hydraulic oil level. Add BIO HY-GARD to appropriate level.

8. Operate machine under normal operating conditions for a minimum of two hours.

10. Follow recommended service intervals.

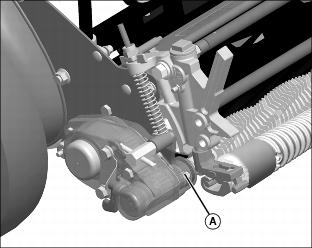

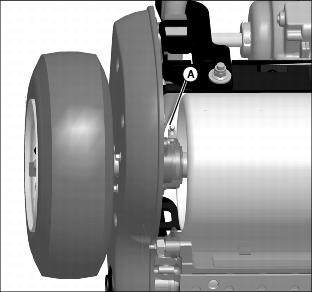

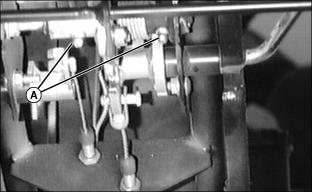

Lubricating Rotary Brush Or GTC (Greens Tender Conditioner)

Lubricate GTC (greens tender conditioner) or rotary brush (both ends) at points (A) with John Deere Multi-Purpose SD Polyurea Grease or equivalent SAE multipurpose grease.

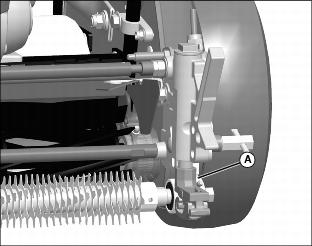

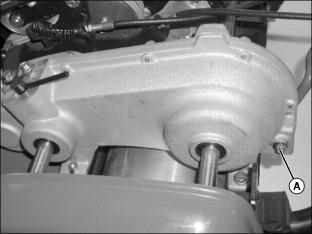

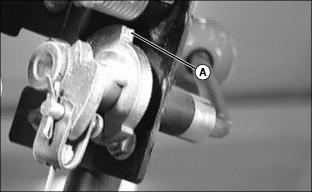

Lubricating Reel

|

Lubricate reel at point (A) (one each side of mower) with John Deere Multi-Purpose SD Polyurea Grease. |

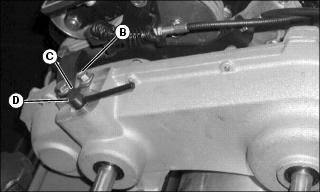

Lubricating Input Drives

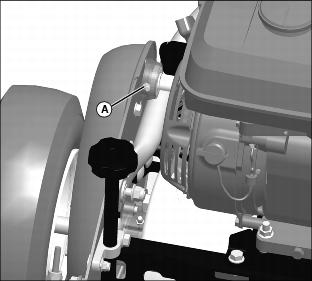

1. Lubricate input drive to ground (right-hand side) drive chain at point (A) with John Deere Multi-Purpose SD Polyurea Grease or equivalent SAE multipurpose grease.

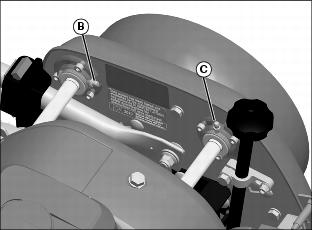

2. Lubricate input drive to ground (left-hand side) drive chain at point (B) with John Deere Multi-Purpose SD Polyurea Grease or equivalent SAE multipurpose grease.

3. Lubricate input drive to reel drive chain at point (C) with John Deere Multi-Purpose SD Polyurea Grease or equivalent SAE multipurpose grease.

Lubricating Front Roller

Lubricate front roller at two points (A) with John Deere Multi-Purpose SD Polyurea Grease or equivalent SAE multipurpose grease.

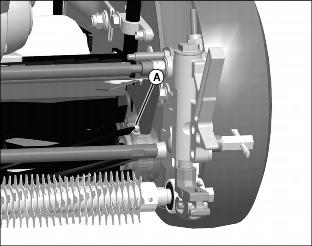

Lubricating Drive Roller

Picture Note: View from under mower.

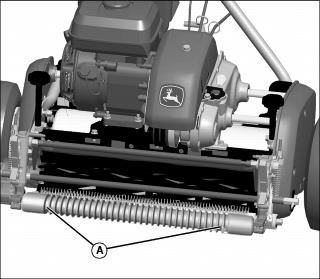

Lubricate drive roller at points (A) with John Deere Multi-Purpose SD Polyurea Grease or equivalent SAE multipurpose grease.

Checking and Filling Gear Case

NOTE: Change gearcase oil after first 50 hours of operation.

1. Put block under front roller to level machine.

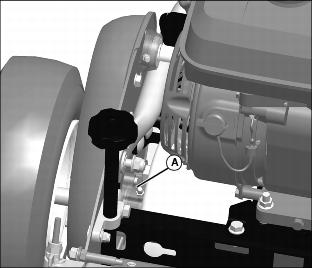

2. Remove drain plug (A) and oil should be at the bottom of drain hole.

4. Refill using John Deere Hy-Gard Oil.

• Oil capacity: 0.4 L (0.4 qt).

7. Rotate spring (C) out of the way.

8. Remove handle (D) and fill.

9. Install in reverse order of removal.

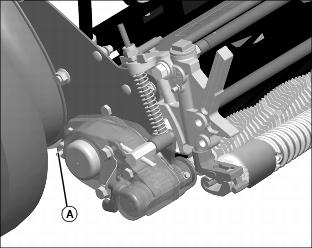

Lubricating Knife Shoe Pivot Bolt

Lubricate knife shoe pivot bolt at point (A) (one on each side of mower) with John Deere Multi-Purpose SD Polyurea Grease or equivalent SAE multipurpose grease.

Lubricating Drive Control Linkage

Lubricate drive control linkage at points (A) with John Deere Multi-Purpose SD Polyurea Grease or equivalent SAE multipurpose grease.

Lubricating Operator Presence Pawl And Cam

Apply grease to operator presence pawl and cam at point (A).

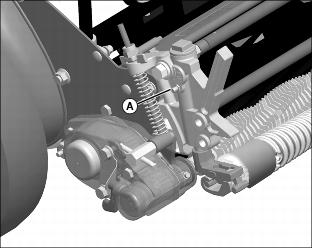

Lubricating Height of Cut Bracket

Lubricating height of cut bracket (both ends) at points (A) with John Deere Multi-Purpose SD Polyurea Grease or equivalent SAE multipurpose grease.