Service Engine

Engine Warranty Maintenance Statement

Maintenance, repair, or replacement of the emission control devices and systems on this engine, which are being done at the customer’s expense, may be performed by any non-road engine repair establishment or individual. Warranty repairs must be performed by an authorized John Deere dealer.

Avoid Fumes

Engine Oil - Diesel

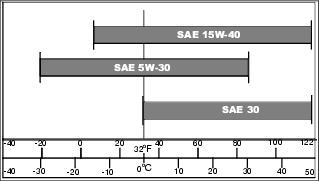

Use oil viscosity based on the expected air temperature range during the period between oil changes.

The following John Deere oils are preferred:

Other oils may be used if above John Deere oils are not available, provided they meet one of the following specifications:

• API Service Classification CG or higher.

hecking Engine Oil Level

NOTE: Check oil twice a day if you run engine over 4 hours in a day.

Make sure engine is cold when checking engine oil level.

1. Park machine safely. (See Parking Safely in the SAFETY Section.)

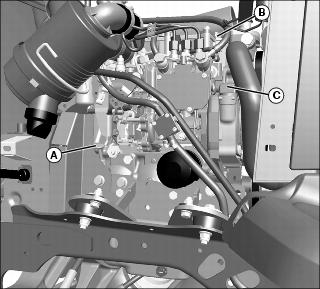

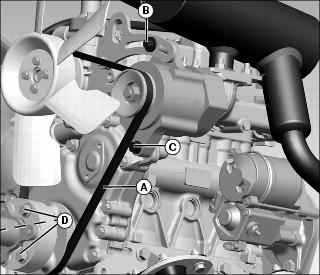

4. Remove dipstick (A). Wipe dipstick with a clean rag.

5. Install dipstick. Be sure dipstick is all the way down.

7. Check oil level on dipstick. Oil level should be between crosshatch marks on dipstick.

8. If oil level is low, remove oil filler cap (B) or (C).

9. Add oil to bring oil level no higher than top of crosshatch mark on dipstick.

11. Install and tighten oil filler cap.

hanging Engine Oil and Filter

IMPORTANT: Avoid damage! Operating in extreme conditions, such as heat or dust, may require more frequent service intervals. |

1. Run engine a few minutes to warm oil.

2. Park machine safely. (See Parking Safely in the SAFETY Section.)

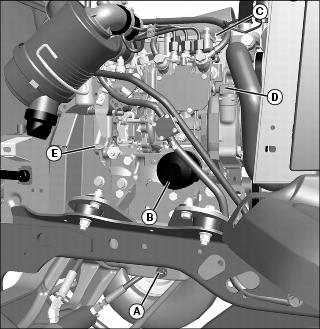

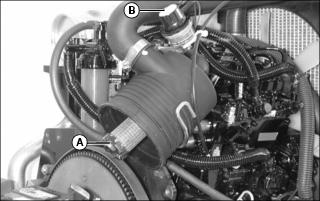

4. Put drain pan under drain plug (A).

6. Allow oil to drain completely.

8. Clean dirt from around oil filter (B).

9. Position drain pan under filter.

10. Turn oil filter counterclockwise with a filter wrench to remove.

11. Put a light coat of clean engine oil on gasket of new filter.

12. Install replacement oil filter by turning oil filter clockwise until gasket contacts filter base. Tighten filter an additional one-half turn.

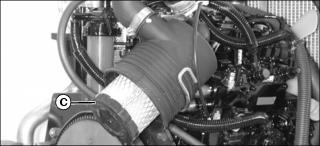

13. Remove oil filler cap (C) or (D). Add approximately 3.2 L (3.4 qt) of oil.

14. Install and tighten filler cap.

15. Start and run engine at idle to check for leaks.

16. Stop engine. Fix any leaks before operating.

17. Remove dipstick (E) and check engine oil level. Add or remove oil if necessary.

leaning Air Intake Screens

• Clear work area of bystanders. • Wear eye protection when using compressed air for cleaning purposes. |

1. Park machine safely. (See Parking Safely in the SAFETY Section.)

4. Clean air intake screens on side panels using a brush, cloth or water.

5. Clean rear air intake screen (B) with a brush, cloth or compressed air. Blow compressed air back toward seat.

hecking Air Restriction Indicator

1. Park machine safely. (See Parking Safely in the SAFETY Section.)

NOTE: Indicator will not function correctly if plastic indicator housing is damaged.

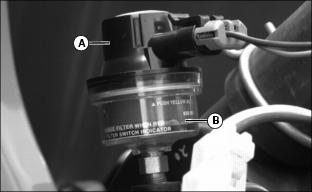

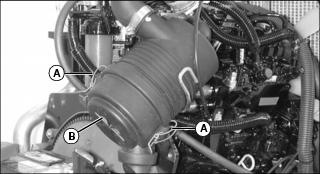

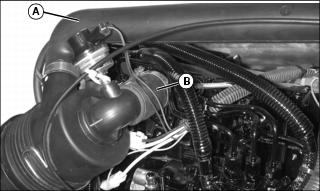

3. Locate and check air restriction indicator (A).

• If window (B) is clear, no air cleaner service is required.

• If window (B) shows fully red, air cleaner requires immediate service.

4. Service air cleaner elements if needed.

5. Push yellow reset button on top of air restriction indicator.

leaning Dust Unloading Valve

IMPORTANT: Avoid damage! Do not operate engine without air cleaner element and rubber dust unloading valve installed. |

1. Park the vehicle safely. (See Parking Safely in the SAFETY section.)

3. Access the engine compartment.

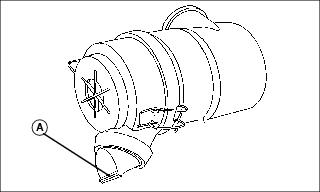

4. Squeeze dust unloading valve (A) to clean. Remove and replace if damaged.

Servicing Air Cleaner Elements

Servicing Primary Air Cleaner Element:

1. Park the machine safely. (See Park Safely in the SAFETY section.)

4. Release latches (A) and remove air cleaner canister cover (B).

5. Remove and discard primary element (C). Replace with new primary element.

6. Install air cleaner canister cover with rubber dust unloading valve pointing downward.

7. Check instruction molded into canister cover for proper installation.

9. Push reset button (D) on air restriction indicator.

10. Start engine. Allow engine to run approximately one minute at maximum throttle speed.

12. Check air restriction indicator.

• If window (E) is clear, no air cleaner service is required.

• If window (E) shows fully red, secondary air cleaner element requires immediate service.

Servicing Secondary Air Cleaner Element:

1. Remove air cleaner canister cover.

2. Remove primary air cleaner element.

3. Remove and discard secondary air cleaner element (A). Replace with a new secondary air cleaner element.

4. Install primary air cleaner element.

5. Replace air cleaner canister cover.

6. Push reset button (B) on air restriction indicator.

hecking Air Cleaner Intake Hoses and Clamps

1. Park the machine safely. (See Park Safely in the SAFETY section.)

4. Check condition of upper (A) and lower (B) air intake hoses. Replace if needed.

5. Check to be sure hose clamps are tight and secure.

Recommended Engine Coolant

The engine cooling system is filled to provide year-round protection against corrosion and cylinder liner pitting, and winter freeze protection to -37 degrees C (-34 degrees F). If protection at lower temperatures is required, consult your John Deere dealer for recommendations.

The following coolants are preferred:

• John Deere COOL-GARD II™ Premix

• John Deere COOL-GARD PG Premix

John Deere COOL-GARD II Premix and John Deere COOL-GARD Premix are available in a concentration of 50% propylene glycol.

John Deere COOL-GARD PG Premix is available in a concentration of 55% propylene glycol.

Additional recommended coolants:

• John Deere COOL-GARD II Concentrate in a 40% to 60% mixture of concentrate with water.

• John Deere COOL-GARD Concentrate in a 40% to 60% mixture of concentrate with water.

If the recommended coolants are unavailable, use an ethylene glycol or propylene glycol base coolant that meets the following specification:

• ASTM D3306 prediluted (50%) coolant.

• ASTM D3306 coolant concentrate in a 40% to 60% mixture of concentrate with water.

heck container label before using to be sure it has the appropriate specifications for your machine. Use coolant with conditioner or add conditioner to coolant before using.

Water Quality

• Water quality is important to the performance of the cooling system. Distilled, deionized, or demineralized water is recommended with ethylene glycol base engine coolant concentrate.

Servicing Cooling System

hecking Coolant Level

1. Park machine safely. (See Parking Safely in the SAFETY Section.)

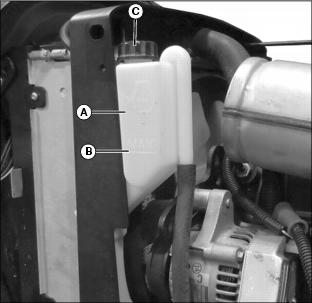

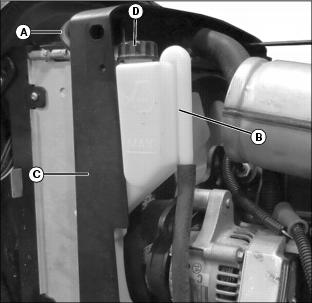

4. Check recovery tank (A) coolant level:

• Coolant should be present in bottle and at or below MAX line (B).

5. Remove recovery tank cap (C) if necessary to add coolant.

6. Add pre-diluted coolant or specified ratio of antifreeze and water.

7. Install and tighten recovery tank cap.

Draining Cooling System

1. Park machine safely. (See Parking Safely in the SAFETY Section.)

4. Slowly open radiator cap (A) to the first stop to release all pressure.

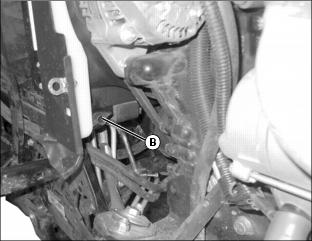

6. Put drain pan under radiator petcock (B) located behind right side panel.

7. Open radiator petcock. Drain coolant into pan.

9. Flush or fill cooling system and install radiator cap.

Flushing Cooling System

NOTE: Cooling system capacity is 2.8 L (3.0 qt).

2. Fill cooling system with clean water and John Deere Cooling System Cleaner, or John Deere Cooling System Quick Flush or an equivalent. Follow directions on can.

3. Install and tighten radiator cap.

4. Run engine until needle on coolant temperature gauge reaches the green range.

6. Drain cooling system immediately before rust and dirt settle.

• Pull overflow hose (A) from pickup tube on top of tank (B) and remove tank from frame bracket (C).

8. Remove tank cap (D) and clean tank.

10. Install overflow hose to pickup tube on top of tank. Be sure hose is not kinked.

Filling Cooling System

NOTE: John Deere COOL-GARD coolant is recommended when adding coolant to the cooling system.

Follow the directions on the container for correct mixture ratio.

1. Park machine safely. (See Parking Safely in the SAFETY Section.)

3. Fill cooling system. Cooling system capacity is 2.8 L (3.0 qt).

• Coolant should be level with lower ridge of radiator neck.

4. Install and tighten radiator cap.

5. Run engine until needle on coolant temperature gauge reaches the green range.

7. Check recovery tank coolant level:

• Coolant should be present in bottle and at or below MAX line.

8. Remove cap from recovery tank to add coolant if necessary.

leaning Radiator Screen and Fins

• Clear work area of bystanders. • Wear eye protection when using compressed air for cleaning purposes. |

1. Park machine safely. (See Parking Safely in the SAFETY Section.)

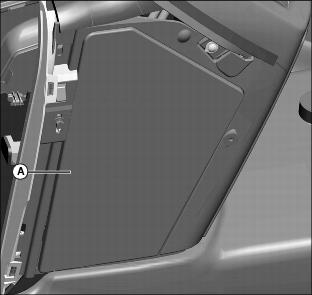

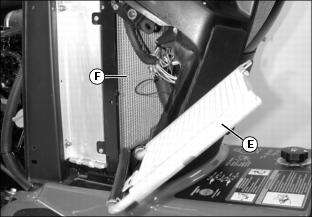

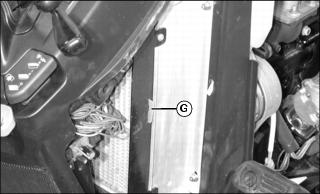

3. Remove side panels (A). (See “Removing and Installing Side Panels” in the SERVICE MISCELLANEOUS section.)

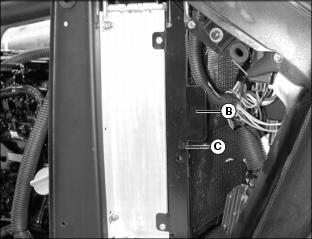

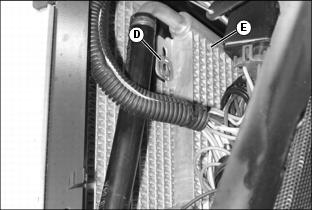

4. Grab handle (B) on screen on left side of machine, and pull screen out slightly to remove from behind tab (C). Remove screen.

5. Clean screen with a brush, compressed air or water from a hose.

6. Turn fastener (D) on left side of machine to unlock position.

7. Carefully remove oil cooler (E) from radiator compartment.

8. Clean oil cooler (E) with gentle hose spray or vacuum cleaner.

9. Clean cooling fins (F) on both sides of radiator.

10. Install oil cooler. Check to be sure tab (G) extends through slot on right side of machine. Turn fastener on left side of machine to lock position.

hecking Radiator Hoses and Clamps

1. Park machine safely. (See Parking Safely in the SAFETY section.)

3. Check radiator hoses for damage or cracking. Replace if needed.

4. Tighten hose clamps as needed.

Servicing Alternator Belt

hecking Belt Tension

1. Park machine safely. (See Parking Safely in the SAFETY section.)

4. Apply moderate thumb pressure to belt (A) halfway between pulleys. Belt should deflect inward approximately 13mm (1/2 in.).

5. Adjust belt tension if deflection is more or less than specified.

Adjusting Belt Tension

2. Loosen alternator bolt (C).

3. Push alternator up to loosen belt, and down to tighten belt.

Replacing Belt

1. Park machine safely. (See Parking Safely in the SAFETY section.)

5. Loosen alternator bolt (C).

6. Push alternator up to loosen belt.

NOTE: Rotate driveshaft for access to bolts, if necessary.

7. Remove three capscrews (D) to disconnect drive shaft from engine sheave.

8. Remove belt from engine sheave, and alternator and fan pulleys. Pull belt over fan.

9. Install new belt loosely around sheave and pulleys.

10. Install driveshaft. Tighten three capscrews to 40 N•m (30 lb-ft).

11. Check belt tension. Adjust as needed.

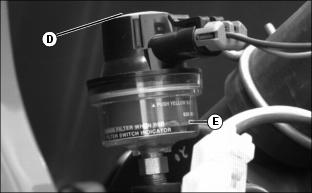

hecking Fuel Filter Sediment Bowl

1. Park machine safely. (See Parking Safely in the SAFETY section.)

NOTE: Red ring in bottom of sediment bowl will float on water. If ring is floating, sediment bowl should be cleaned.

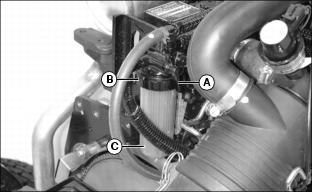

4. Check for water and deposits in bottom of sediment bowl (A).

5. Clean sediment bowl and replace fuel filter if needed.

leaning Fuel Filter Sediment Bowl and Replacing Filter

NOTE: Change filter when fuel is low.

1. Park machine safely. (See Parking Safely in the SAFETY section.)

Picture Note: Fuel shut-off valve shown in open position

4. Close fuel shut-off valve (A).

5. Put drain pan under fuel filter sediment bowl to catch fuel spillage.

6. Turn locking collar (B) counterclockwise to remove bowl (C).

7. Remove and discard fuel filter.

8. Remove and retain plastic ring and spring from sediment bowl.

9. Clean bowl, plastic ring and spring.

10. Install plastic ring and spring in original position in sediment bowl.

11. Install new filter on filter head.

12. Position sediment bowl and locking collar. Tighten locking collar to filter head.

15. Start machine and check for leaks.

Adjusting Fuel Injection Pump

NOTE: The fuel injection pump is calibrated by the engine manufacturer and should not require any adjustments.

If engine is hard to start, lacks power, or runs rough, check the TROUBLESHOOTING section of this manual.

After performing the checks in the troubleshooting section, if your engine is still not performing correctly, contact your John Deere dealer.