Service Lubrication

Grease

The following greases are preferred:

John Deere Multi-Purpose SD Polyurea Grease

John Deere Multi-Purpose HD Lithium Complex Grease

If not using any of the preferred greases, be sure to use a general all-purpose grease with an NLGI grade No.2 rating.

Wet or high speed conditions may require use of a special-use grease. Contact your Servicing dealer for information.

Lubricating Drive Line

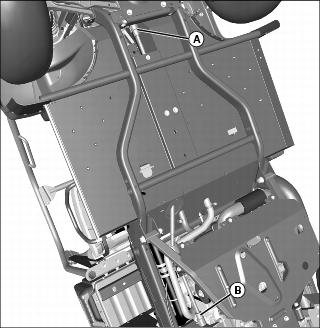

Picture Note: Viewed from under the machine.

1. Lubricate two grease fittings (A) on front drive line with one or two shots of grease.

2. Remove two bolts on rear belt cover, and lubricate two grease fittings (B) on rear drive line with one or two shots of grease.

Lubricating Suspension

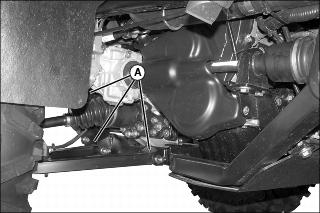

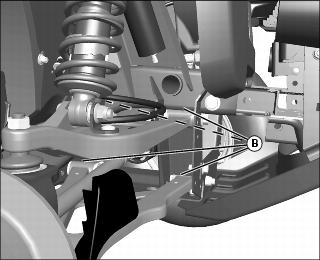

Early production machines are equipped with grease fittings on pivot points as shown below. Later production machines will use bonded no-grease fitting joints.

Lubricate control arm to frame pivot (14 locations)

1. Park machine safely (see Parking Safely in the SAFETY Section).

Picture Note: Three grease fitting locations (A) on right rear side of machine shown.

Picture Note: Four grease fitting locations (B) on right front side of machine shown.

2. Using a grease gun, apply grease to joints through the grease fittings until grease become visible at joint interface. Repeat on opposite side of machine.

3. Remove exposed grease from joint after applying grease.

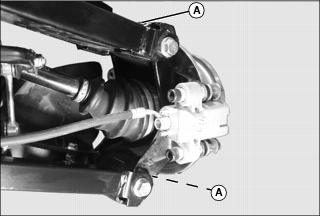

Lubricate rear control arm to upright (4 locations)

1. Park machine safely (see Parking Safely in the SAFETY Section).

2. Block front tires front and back.

3. Raise rear of machine with a safe lifting device and lower machine onto jack stands or other stable support.

6. Using a grease gun, apply grease to joints through the grease fittings (A) until grease become visible at joint interface. Repeat on opposite side of machine.

7. Remove exposed grease from joint after applying grease.

8. Install wheel assembly with valve stem to the outside.

9. Tighten wheel bolts evenly in alternating sequence until snug.

10. Lower machine completely to the ground.