Introduction

Safety Signs

Controls

Operating

Replacement Parts

Service Machine Safely

Service

Engine Warranty Maintenance Statement

Cleaning / Changing Air Cleaner

Cleaning and Gapping Spark Plug

Adjusting "Forward" Drive Belt Tension

Adjusting "Reverse" Drive Belt Tension

Lubricating Drive Idler Sheaves

Troubleshooting

Storing Machine

Assembly

Specifications

Warranty

John Deere Quality Statement

Copyright© Deere & Company

Service

Engine Warranty Maintenance Statement

Maintenance, repair, or replacement of the emission control devices and systems on this engine, which are being done at the customers expense, may be performed by any nonroad engine repair establishment or individual. Warranty repairs must be performed by an authorized John Deere dealer.

Service Intervals

· Change gearbox oil. (after initial purchase) |

|

· Change gearbox oil. (after initial purchase) · Clean engine cylinder cooling fins. |

|

· Clean / Change air filter element. |

Service Record

Avoid Fumes

· If it is necessary to run an engine in an enclosed area, use an exhaust pipe extension to remove the fumes. |

Engine Oil

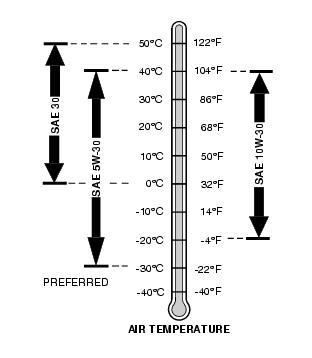

Use oil viscosity based on the expected air temperature range during the period between oil changes.

The following John Deere oils are PREFERRED:

The following John Deere oils are also recommended, based on their specified temperature range:

Other oils may be used if above John Deere oils are not available, provided they meet one of the following specifications:

· SAE 30-API Service Classification SC or higher;

· SAE 5W-30-API Service Classification SG or higher;

· SAE 10W-30-API Service Classification SG or higher.

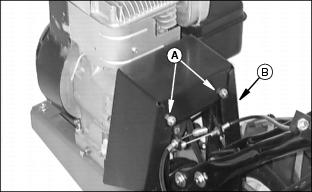

Checking Engine Oil Level

IMPORTANT: Avoid damage! Oil level MUST be maintained in a safe operating range at all times or engine damage will result. |

Service Interval: Check oil level daily or every 5 hours of operation.

1. Park tiller on a flat level surface, stop engine and disengage clutches.

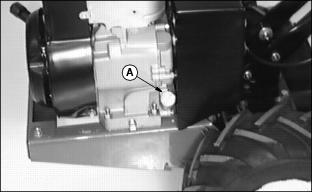

2. Wipe all debris from around oil fill plug.

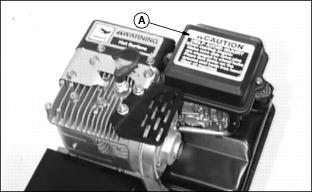

3. Remove oil fill plug (A) and observe oil level:

· Oil level must be at level (B).

NOTE: See Engine Oil in this section for proper type of oil.

· If necessary add clean fresh engine oil through oil fill plug until FULL, oil level (B).

· Approximate crankcase capacity is 0.56 L (19 oz.)

· DO NOT over fill. Level must not exceed FULL mark.

Changing Engine Oil

Service Interval: Change engine oil after first 2 hours of operation, thereafter change oil every 25 hours of operation or yearly.

1. Run engine just prior to changing oil. Oil will flow more freely and carry away more contamination when warm.

2. Park tiller on a flat level surface, stop engine.

· Position a drain pan under engine.

· After engine oil has completely drained, install oil drain plug.

NOTE: See Engine Oil in this section for proper type of oil.

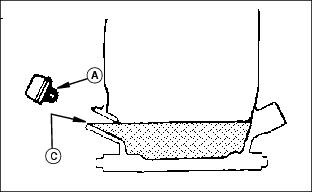

· Add clean fresh engine oil through oil fill plug (A) until FULL, oil level (C).

· Approximate crankcase capacity is 0.56 L (19 oz.).

· DO NOT over fill. Level must not exceed FULL mark.

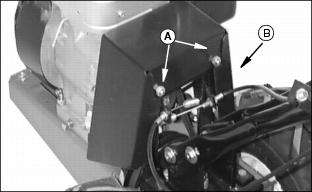

Cleaning / Changing Air Cleaner

Service Interval: Inspect filter element every 25 hours of operation and replace if damaged or dirty. Check more frequently under extremely dirty, dusty conditions.

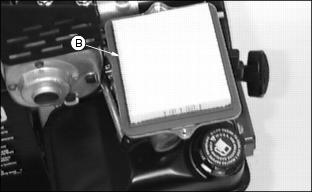

1. Remove air cleaner cover (A).

2. Remove air filter element (B).

3. Clean or replace element every 25 hours of operation:

· If air filter is dirty, tap gently on your hand to remove dust.

· If air filter is extremely dirty, install a new element.

4. Install air cleaner cover (A).

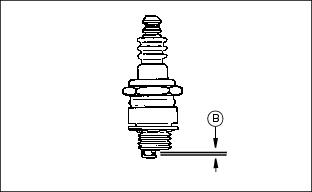

Cleaning and Gapping Spark Plug

Service Interval: Check spark plug every 100 hours of operation or yearly.

1. Clean area around spark plug.

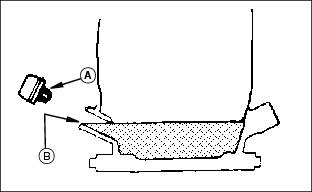

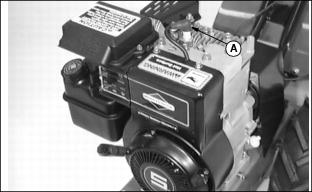

2. Disconnect spark plug wire (A).

3. Remove and inspect spark plug:

· Clean plug and check for damage, replace if necessary.

· If plug is in good condition, check gap.

4. Check and adjust spark plug gap (B):

5. Install spark plug and tighten to 20 N·m (15 lb-ft.).

Cleaning Cylinder Fins

Service Interval: Clean cylinder fins every 50 hours of operation or yearly, or more often under extremely dirty, dusty conditions.

This engine is air cooled. Air must circulate freely around engine from air intake screen, and over cooling fins on cylinder head and block, to prevent overheating.

Remove cooling shrouds and clean engine fins. Also clean external surfaces of engine of dust, dirt and oil deposits which can contribute to improper cooling.

IMPORTANT: Avoid damage! DO NOT run engine with cooling shrouds removed. This will cause overheating and engine damage. |

Adjusting Carburetor

NOTE: The carburetor is calibrated by the engine manufacturer and should not require any adjustments.

If engine is operated at altitudes above 1829 m (6,000 ft.), some carburetors may require a special high altitude main jet. See your John Deere dealer.

Possible engine surging will occur at high rpm when the machine is in neutral ("N") and the tines are disengaged. This is a normal condition due to the emission control system.

If engine is hard to start or runs rough, check the TROUBLESHOOTING section of this manual.

After performing the checks in the troubleshooting section and your engine is still not performing correctly, contact your John Deere dealer.

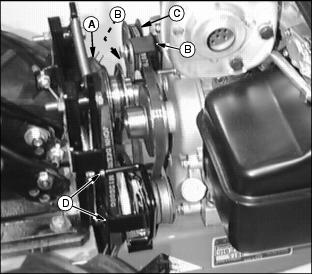

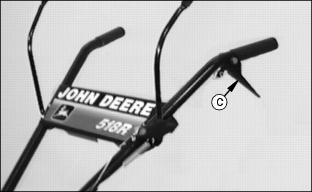

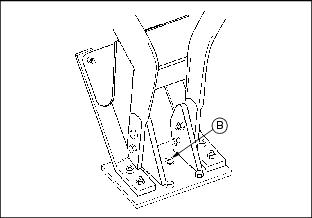

Removing and Installing Belts

NOTE: The FORWARD and REVERSE drive belts must each be partially removed in order to remove either belt from the machine.

1. Remove the spark plug wire.

2. Remove nuts on the belt guard and take the guard off the unit.

NOTE: The REVERSE belt (C) is installed on the front sheaves and the FORWARD belt (A) is installed on the rear sheaves.

3. Remove the FORWARD belt from the top sheave.

4. Remove the REVERSE belt from the upper and lower sheaves. Pull the belt down and out from under the machine.

5. Remove the FORWARD belt from the lower sheave and pull down and out from under the machine.

6. Bring REVERSE belt (C) from under machine and install on top sheaves. Make sure the belt is installed properly under belt guides (B) on top and left side of machine.

7. Install FORWARD belt (A) on appropriate set of sheaves at rear. (Front set of sheaves is for FAST speed and rear set is for SLOW speed.)

8. Install REVERSE belt on lower sheave. Make sure the belt is routed on correct side of belt guides (D).

9. Install belt guard onto machine.

10. Connect the spark plug wire.

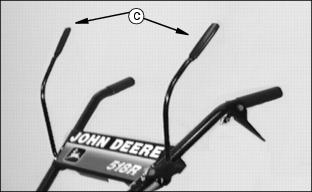

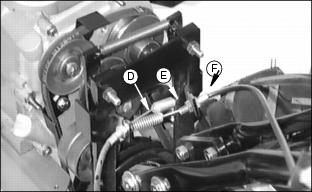

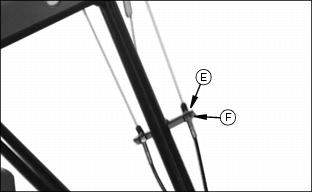

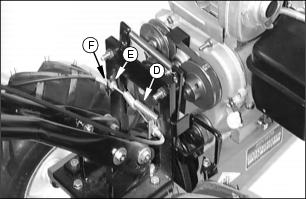

Adjusting "Forward" Drive Belt Tension

1. Remove two nuts (A) and belt cover (B).

2. Operate and hold main clutch "F" Top Levers (C) in the engaged position.

IMPORTANT: Avoid damage! When adjusting belt tension do not tighten cable so much that the engagement spring (D) is expanded 19 mm (3/4 in.) longer than it's relaxed state length. |

NOTE: Cable length can be adjusted at either end, it is suggested to adjust cable on the handlebar end first.

· Tighten or loosen nut (F) until the engagement spring (D) has expanded in length approximately 6 mm (1/4 in.) from it's relaxed state length.

If belt has stretched too much and tension cannot be adjusted, install a new belt.

4. Install belt cover and nuts.

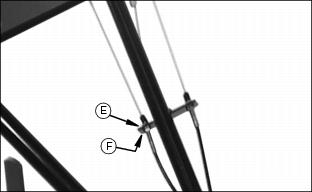

Adjusting "Reverse" Drive Belt Tension

1. Remove two nuts (A) and belt cover (B).

2. Operate and hold main clutch "R" Bottom Lever (C) in the engaged position.

IMPORTANT: Avoid damage! When adjusting cable pull do not tighten cable so much that the engagement spring (D) is expanded 19 mm (3/4 in.) longer than it's relaxed state length. |

NOTE: Cable length can be adjusted at either end, it is suggested to adjust cable on the handlebar end first.

· Tighten or loosen nut (F) until the engagement spring (D) has expanded in length approximately 6 mm (1/4 in.) from it's relaxed state length.

If belt has stretched too much and tension cannot be adjusted, install a new belt.

4. Install belt cover and nuts.

Checking Tire Pressure

Check tire pressure with an accurate gauge.

· Tire pressure should be 96 kPa (14 PSI).

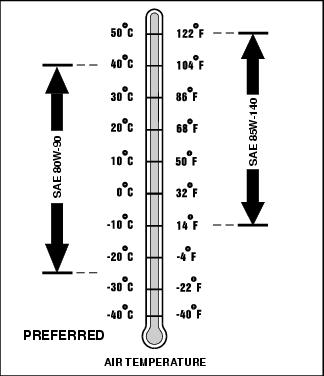

Gear Oil

Use oil viscosity based on the expected air temperature range during the period between oil changes.

The following John Deere gear case oil is PREFERRED:

The following John Deere gear case oil is also recommended if above preferred oil is not available:

Other gear case oils may be used if above recommended John Deere gear case oils are not available, provided they meet the following specification:

· API Service Classification GL-5.

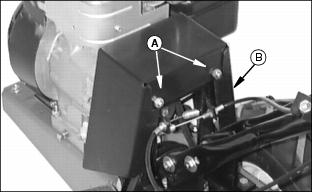

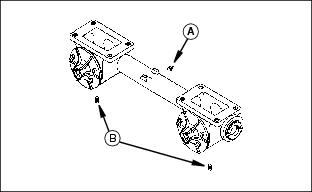

Checking Gearbox Oil Level

IMPORTANT: Avoid damage! Serious damage can be caused to your gearbox if it is allowed to run for even a short time without proper amount of oil. |

Service Interval: Check gearbox oil level every 5 hours of operation or at start of tilling season (yearly).

1. Place tiller on a flat level surface.

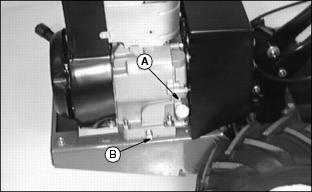

2. Remove the oil level (vent) plug (A).

3. Check oil level. Oil level should run out of or be up to check hole.

4. If necessary, clear all dirt from fill port area and add oil at the oil fill port (B). (See Gear Oil in this section for correct oil.)

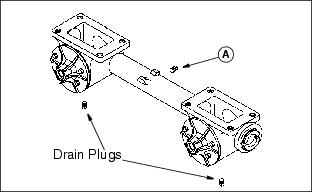

Changing Gearbox Oil

Service Interval: Drain and refill gearbox after first 25 hours of operation or at the end of first season, whichever comes first, thereafter change oil only if repair parts are installed or you see contaminant's in the oil.

1. Run engine and tiller just prior to changing oil. Oil will flow more freely and carry away more contamination when warm.

2. Place tiller on a flat, level surface.

· Wipe all debris from around oil plugs (A, B and C).

· Remove oil level (vent) plug (A).

· Place a shallow drain pan below drain plugs (B).

· After oil has completely drained, install oil drain plugs securely.

NOTE: See Gear Oil in this section for proper type of oil.

· Add clean fresh oil through oil fill plug hole (C).

· Approximate gearbox capacity is 946 mL (32 oz.).

· When gearbox is FULL, oil should run out of or be even with bottom of oil level plug hole (A). DO NOT over fill.

· Install and tighten oil plugs (A and C).

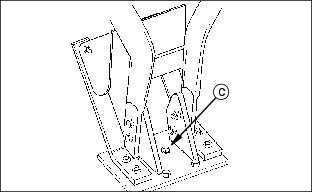

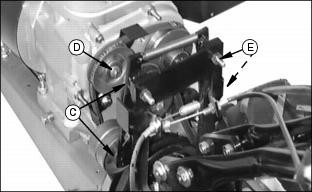

Lubricating Drive Idler Sheaves

IMPORTANT: Avoid damage! DO NOT over lubricate or use grease on the idler sheaves. Dirt and dust will tend to collect on any exposed lubricated parts. |

Service Interval: Lubricate drive idler sheaves every 25 hours of operation or yearly, or more often under extremely dirty, dusty conditions.

1. Remove two nuts (A) and belt cover (B).

2. Lightly oil bearings on (forward drive belt) idler sheave and idler arm pivots (C).

· Idler sheave should spin freely.

· Idler arm should pivot smoothly and return to the disengaged position by spring force.

3. Lightly oil bearings on (reverse drive belt - stationary idler) idler sheave (D).

· Idler sheave should spin freely.

4. Lightly oil bearings on (reverse drive belt) idler sheave and idler arm pivots (E).

· Idler sheave should spin freely.

· Idler arm should pivot smoothly and return to the disengaged position by spring force.

5. Install belt cover and nuts.

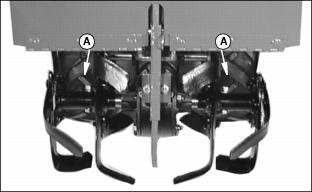

Lubricating Drive Wheels

Service Interval: Lubricate drive wheel axles on a yearly basis.

1. Raise and support tiller so that drive wheels are off the ground.

2. Remove wheel hub drive pins (A).

4. Lubricate axle and inside of drive wheel hub with a general purpose grease or oil. This lubrication is to prevent rusting and seizing.

5. Install drive wheels with traction ARROW pointing forward as shown on the tire sidewall.

Lubricating Tine Shafts

Service Interval: Lubricate tine shafts on a yearly basis.

1. Remove locknuts and bolts (A) to remove tines.

2. Lubricate tine shafts and inside of tine hubs with a general purpose grease or oil. This lubrication is to prevent rusting and seizing.

3. Install tines with the cutting edges pointing towards the front of the tiller.

4. Install and tighten hardware.

Fuel

IMPORTANT: Avoid damage! Avoid spilling fuel. Fuel can damage plastic and painted surfaces. DO NOT mix oil with gasoline. Unleaded gasoline with an octane rating of 87 or higher is recommended. |

· Use only clean, fresh, unleaded regular grade gasoline.

· Remove any trash from top of fuel tank drain area.

· Use summer blended fuel for warm weather operation and winter blended fuel for cold weather.

· Never use fuel that is stale or has been stored for a long period of time:

Warm Weather - Maximum 60 days.

Cold Weather - Maximum of 90 days.

· Fill fuel tank at the end of each day's operation. This helps to keep condensation out of fuel tank.

Oxygenates (either ethanol or MTBE) are added to the gasoline. If you use the oxygenated fuel be sure it is unleaded and meets the minimum octane rating requirement.

The following are the EPA approved percentages of fuel oxygenates:

ETHANOL (Ethyl or Grain Alcohol): You may use gasoline containing up to 10 percent ethanol by volume.

MTBE (Methyl Tertiary Butyl Ether): You may use gasoline containing up to 15 percent MTBE by volume.

METHANOL (Methyl or Wood Alcohol): You may use gasoline containing up to 5 percent methanol by volume, as long as it also contains cosolvents and corrosion inhibitors to protect the fuel system. Gasoline containing more than 5 percent methanol by volume may cause starting and/or performance problems. It may also damage metal, rubber, and plastic parts of your fuel system.

1. STOP engine. If engine is hot let it cool several minutes before you add fuel.

Approximate fuel tank capacity 2.8 L (3 Qts.)