Introduction

Product Identification

Safety

Operating

Replacement Parts

Service Interval Chart

Service Lubrication

Service Engine

Service Transmission

Service Mower and Grass Collector

Service Electrical

Service Miscellaneous

Troubleshooting

Storage

Assembly

Install Grass Collector Switch

Checking Machine Safety System

Specifications

Warranty

John Deere Quality Statement

Service Record

CopyrightŠ Deere & Company

Assembly

Bag of Parts

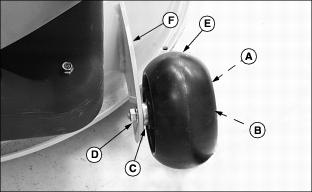

Install Mower Wheels

NOTE: Mower wheels are bolted to the front tires and hardware required to install them is attached to the mower wheel brackets for shipping purposes.

1. Remove bolt (A), washer (B), spacer (C), and nut (D) from each mower wheel bracket.

2. Install mower wheel (E) to the OUTSIDE of mower bracket (F), one on each side, using bolt (A), washer (B), spacer (C) and nut (D).Tighten nut to 34 Nˇm (25 lb-ft).

3. Adjust mower level before operation.

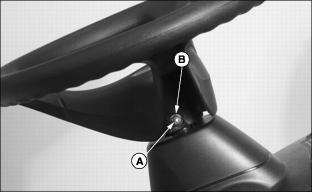

Install Steering Wheel

1. Put front wheels in the straight forward position.

2. Put John Deere NEVER-SEEZ Lubricant or an equivalent on the steering shaft.

3. Install steering wheel with John Deere logo in the upright position.

4. Install shoulder bolt (A). Drive bolt in until head of bolt contacts steering wheel.

5. Install washer and nut (B).

6. Tighten lock nut until it is snug. Do not pull washer or head of bolt into steering wheel.

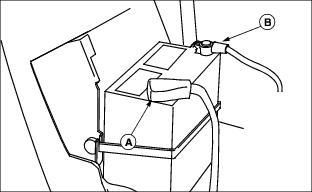

Charge and Connect Battery

1. Remove and discard the red (+) positive, and black negative (-) protective caps from the battery terminals.

3. Clean both battery terminals and battery cable ends with a wire brush until bright.

4. Connect red positive (+) cable (A) to battery. Apply petroleum jelly or silicone spray to terminal to prevent corrosion. Make sure connection is tight. Install the red terminal cover.

5. Connect black negative (-) cable (B) to battery. Apply petroleum jelly or silicone spray to terminal to prevent corrosion. Make sure connection is tight.

Fill Fuel Tank

IMPORTANT: Avoid damage! The fuel tank is dry when the machine is shipped. Damage may occur to the fuel pump if the ignition key is turned on before fuel is added to the tank. |

2. Fill tank with fresh fuel only to bottom of filler neck.

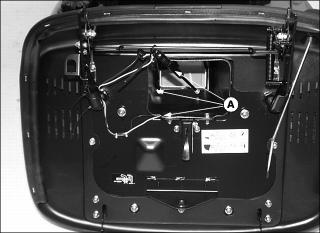

Install Gas Cylinders

NOTE: The gas cylinders are strapped to the grass collector support bracket at the rear discharge opening for shipping purposes. The cotter pins and washers are in the Bag of Parts.

1. Remove tie strap and two gas cylinders (A) from rear support bracket.

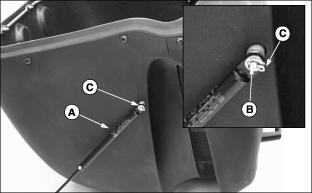

2. Fasten each gas cylinder, one on each side, to outside bucket pin (B) with washer and cotter pin (C) from bag of parts.

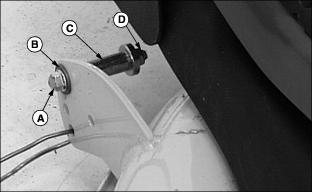

Install Grass Collector Switch

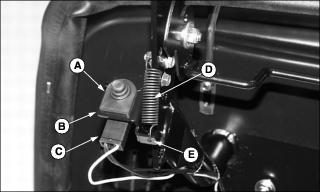

1. Install black rubber cover on bagger presence switch.

2. Install switch (A) in bracket (B) on left bucket support bracket.

3. Install connector (C) to bottom of bagger presence switch.

4. Install spring (D) in hole (E) of switch bracket and bucket support bracket.

Install Grass Collector

1. Pull release handle (A) out to put support brackets (B) in the unlocked (open) position.

2. Align inside bar of grass collector with open support brackets and set bar into brackets.

3. Push release handle (A) down to close support brackets.

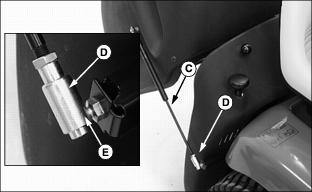

4. Attach gas cylinders (C) to tractor, one on each side, by aligning slot in fastener (D) with ball joint (E) and releasing fastener down to close.

5. Push grass collector down to close.

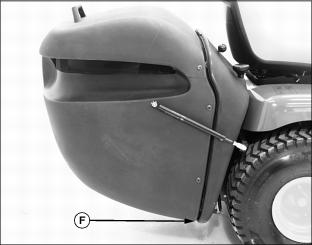

6. Check gap (F) at bottom of grass collector.

7. Adjust bucket latches for tighter fit between grass collector and back plate if necessary:

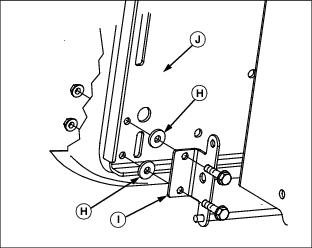

a. Open grass collector bucket.

Picture Note: Bucket removed for photo clarity only.

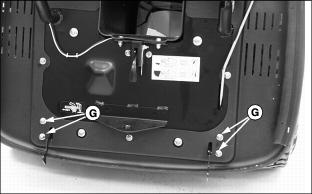

b. Remove four bolts and nuts (G).

c. Install additional washers (H) between latch brackets (I), one on each side, and back plate (J).

d. Remove or add washers after use for tighter fit.

Check Tire Pressure

2. Check tire pressure with an accurate gauge.

3. Add or remove air, if necessary.

Checking Machine Safety System

Perform safety system check to make sure the electronic safety interlock circuit is functioning properly.