Introduction

Product Identification

Safety

Operating

Avoid Damage to Plastic and Painted Surfaces

Using Discharge Chute Controls

Replacement Parts

Service Intervals

Service

Troubleshooting

Storage

Assembly

Specifications

Warranty

John Deere Quality Statement

Service Record

CopyrightŠ Deere & Company

Operating

Daily Operating Checklist

Avoid Damage to Plastic and Painted Surfaces

ˇ Do not wipe plastic parts unless rinsed first.

ˇ Be careful not to spill fuel on machine. Fuel may damage surface. Wipe up spilled fuel immediately.

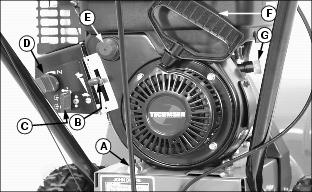

Engine Controls

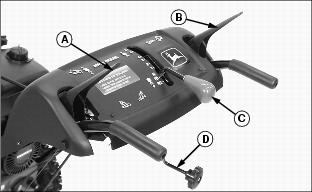

Console Controls

Adjusting Scraper Blade

1. Park snowblower on a hard, smooth surface.

2. Stop engine, remove key, wait for all moving parts to stop.

3. Remove wire from spark plug to prevent accidental starting.

4. Tip unit back onto handle bars and support housing.

5. Adjust skid shoes to their full up position.

ˇ If scraper blade has excessive wear, replace it.

ˇ If scraper blade can be adjusted; loosen nuts and reposition scraper blade, flush with skid shoes.

8. Adjust skid shoes to the proper height.

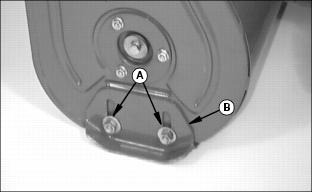

Adjusting Skid Shoes

Adjust skid shoe height for proper working conditions:

ˇ To operate on a smooth, hard surface: Adjust skid shoes so there is 3mm (1/8 in.) between scraper blade and surface.

ˇ To operate on gravel or uneven surface: Adjust skid shoes so there is 30mm (1-1/4 in.) between scraper blade and surface.

ˇ To operate on hard packed snow: Remove skid shoes and install them upside down. This will prevent the snowblower from riding up on the snow. Adjust skid shoes so there is 3mm (1/8 in.) between scraper blade and surface.

1. Park snowblower on a hard, smooth surface.

2. Stop engine, remove key, wait for all moving parts to stop.

3. Remove wire from spark plug to prevent accidental starting.

ˇ Air pressure in both tires should be equal, although some machine leveling can be made by using different pressures. Check for a maximum of 165 kPa (24 psi) in each tire.

ˇ Each tire must be resting on hard surface, not a cross-link of tire chain.

5. Put a block under auger housing.

ˇ If skid shoes have excessive wear, replace them.

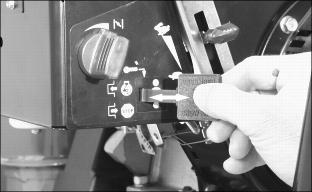

ˇ If skid shoes can be adjusted; loosen two nuts (A) and move skid shoe (B) to desired position.

7. Tighten nuts. Adjust other skid shoe to the same height.

Using Drive Control Levers

Traction Drive Lever (A):

ˇ Pull lever (A) to handle to engage the traction drive.

ˇ Release lever to disengage traction drive.

ˇ Traction drive lever (A) works independently from the auger drive lever (B).

ˇ If unit does not respond, is slow to respond or engages too aggressively when the traction drive lever is engaged, adjust traction drive clutch.

Auger Drive Lever (B):

ˇ Pull lever (B) to handle to engage the auger drive.

ˇ Release lever to disengage auger drive.

ˇ Auger drive lever (B) works independently from the traction drive lever (A).

ˇ If auger is not throwing snow very well or it feels like the auger drive belt is slipping when the auger drive lever is engaged, adjust auger drive belt tension.

ˇ If the auger does not come to a complete STOP in 5 seconds or less after the auger drive lever is released, adjust impeller / auger brake.

Using Speed Selector Lever

IMPORTANT: Avoid damage! DO NOT overload machine capacity by attempting to clear snow at too fast a rate. |

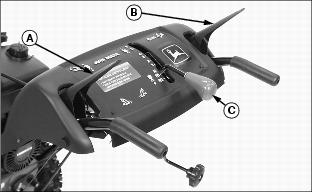

ˇ The speed selector lever (A) controls the units forward speed and reverse motion.

ˇ Moving the speed selector lever forward increases forward travel. There are six forward speeds available: "1" is the slowest speed and "6" is the fastest speed.

ˇ Moving the speed selector lever rearward increases reverse travel. There are two reverse speeds available: "R1" is the slowest speed and "R2" is the fastest speed.

To Operate Speed Selector Lever:

ˇ With engine running, position speed selector lever in the notch of the desired speed and ENGAGE the traction drive lever (B).

ˇ Forward speed can be changed without decollating (releasing traction drive lever).

ˇ DO NOT change motion from forward to reverse with traction drive lever ENGAGED.

ˇ Release traction drive lever to STOP forward or reverse travel.

ˇ Drive wheel slippage will occur as the traction drive wheel wears.

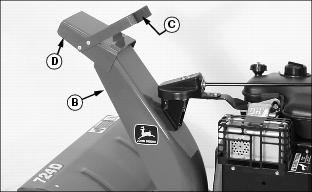

Using Discharge Chute Controls

ˇ DO NOT put hands or feet near or under rotating parts. |

DISCHARGE CHUTE

ˇ The discharge chute control (A) will rotate the discharge chute (B).

ˇ The discharge chute will rotate (full right, straight ahead, or full left).

ˇ If discharge chute is too difficult to rotate or is too loose.

Chute Deflector

ˇ The chute deflector lever (C) will assist in positioning the chute deflector (D):

ˇ The chute deflector will determine how high or low snow will be thrown.

ˇ If the chute deflector becomes difficult to move or is too loose.

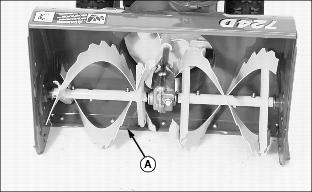

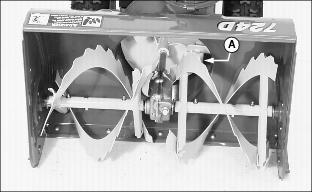

Pre-Starting Engine

IMPORTANT: Avoid damage! In very cold weather, check impeller to be sure it is not frozen. Starting with a frozen impeller could damage the unit. |

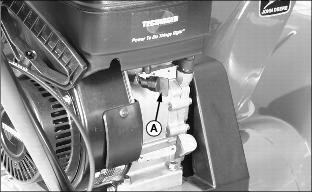

To check unit for a frozen impeller (A):

1. Disconnect spark plug wire from spark plug.

3. Pull engine rewind starter.

If impeller is frozen: Rewind starter can not be pulled. Move unit to a heated area so ice around impeller can thaw.

If Impeller is not frozen: Rewind starter can be pulled - it will be more difficult than normal.

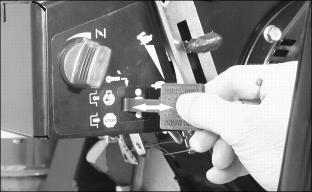

Starting Engine

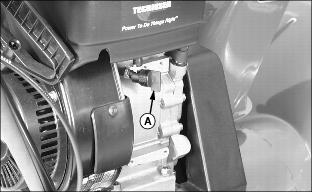

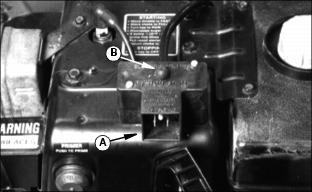

1. Check fuel shut off valve (A). Valve must be in the full open position.

2. Traction drive lever (B) and auger drive lever (C) must be in the DISENGAGED position.

3. Speed selector lever (D) should be in the "N" NEUTRAL position.

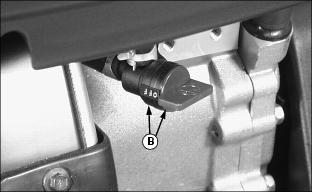

NOTE: The engine ignition key is a two position PUSH/PULL design. DO NOT twist key after it is installed.

4. Install engine ignition key and PUSH it into the "START" position.

ˇ "START" position. To enable the ignition system, push key all the way in until you feel it "Click" into place.

ˇ "STOP" position. To disable the ignition system, pull key all the way out.

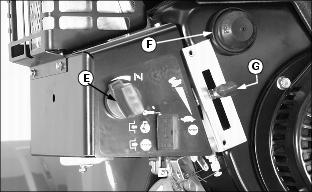

5. Turn choke control knob (E) to choke engine. This engine is equipped with a three position choke:

ˇ Cold engine: Turn choke knob clockwise to the full position.

ˇ Warm / Hot engine: Turn choke knob to the off position or the middle position, depending on engine temperature.

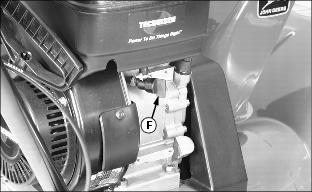

6. Push primer bulb (F) to force fuel into the carburetor, be sure to cover vent hole in primer bulb:

ˇ Cold engine: Push primer bulb quickly two or three times. When temperatures go below -10° C (15° F) repeat priming may be needed.

ˇ Warm / Hot engine: Push primer bulb once or not at all depending on engine temperature.

7. Move throttle lever (G) to set engine speed:

ˇ Cold engine: Set throttle lever at 1/2 to 3/4 fast position.

ˇ Warm / Hot engine: Set throttle lever in the slow position.

a. Pull starter handle (H) until you feel resistance within the engine.

b. Then pull handle fast and steady.

c. Do not let handle snap back.

d. Repeat steps 6 and 8 until engine starts.

If starter handle is frozen and will not crank engine:

a. Pull as much rope out of starter as possible.

b. Release starter handle and let it snap back against starter, repeat as required.

IMPORTANT: Avoid damage! The house circuit you use should be protected by a 20 amp fuse. ˇ A smaller fuse may burn out when you use the electric starter. |

NOTE: The electric starter motor will shut off automatically if it overheats from cranking the engine. After the motor cools, it will operate again.

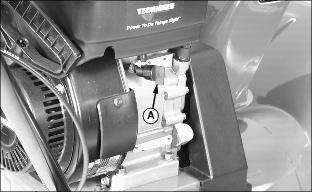

1. Connect power cord to engine switch box (A).

2. Plug other end of cord into three-hole, grounded 120-volt AC. receptacle.

3. Push starter button (B) to start engine.

4. Disconnect cord from house circuit first. Then disconnect cord from switch box.

ˇ Slowly move choke knob to the off position.

ˇ Slowly move throttle lever to desired engine speed.

Stopping Engine

Follow steps below before you park, inspect, adjust, or unplug snowblower.

1. Release traction drive lever (A) and auger drive lever (B):

2. Put speed selector lever (C) in the "N" NEUTRAL position.

3. Slowly move throttle lever (D) to the "STOP" position. Engine will stop.

NOTE: The engine ignition key is a two position PUSH/PULL design. DO NOT twist key after it is installed.

4. Pull engine ignition key out.

ˇ "START" position. To enable the ignition system, push key all the way in until you feel it "Click" into place.

ˇ "STOP" position. To disable the ignition system, pull key all the way out.

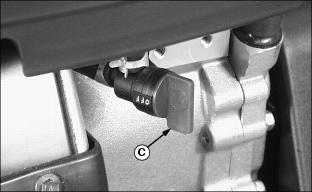

5. Move fuel shut off valve (F) to the CLOSED (OFF) position.

Using Fuel Shut Off

The engine in your snowblower is equipped with a two position fuel shut off valve (A).

ˇ When performing any type of engine service.

ˇ Fuel shut off valve must be in the full OPEN position for proper fuel delivery to the engine.

Emergency Stopping

To stop snowblower in an emergency, release levers.

ˇ Stop auger. If the auger does not come to a complete stop in 5 seconds or less after the auger drive lever is released.

Engine will not stop. Remove engine ignition key to stop engine.

Transporting

Transporting A Short Distance:

ˇ When transporting unit to and from area to be cleared, press down on handlebars enough to raise front of snowblower slightly off surface.

ˇ Engage traction drive lever to propel unit. Do not engage auger drive while transporting.

Transporting A Long Distance:

ˇ When transporting this snowblower on a trailer or in a truck, make sure unit is secured to prevent it from sliding or tipping over.

ˇ Move fuel shut off valve (A) to the closed (OFF) position.

Snowblowing Tips

ˇ For best snowblower performance, run engine with throttle lever in the fast position.

ˇ Do not operate unit at high transport speeds on slippery surfaces and use care when backing.

ˇ Do not overload machine capacity by attempting to clear snow at too fast a rate.

ˇ Match ground speed to amount of snow to be moved. Example: Low speed (1) is recommended for removing deep or hard packed snow.

ˇ Clear snow immediately after it falls, if possible.

ˇ Blow snow downwind, if possible.

ˇ Overlap each swath slightly for complete snow removal.

ˇ Run snowblower a few minutes after blowing snow to prevent freeze up of auger/impeller.

ˇ Pull the starter handle several times to help prevent moisture in the starter from freezing.