PIN (122001-) (133001-) (144001-)

IntroductionProduct Identification

Safety

Operating

Replacement Parts

Service Intervals

Service Lubrication

Lubricating Tractor Grease Fittings

Service Engine

Service Transmission

Service Electrical

Service Miscellaneous

Troubleshooting

Storage

Assembly

Specifications

Warranty

John Deere Quality Statement

Service Record

Service Lubrication

Grease

The following greases are preferred:

· John Deere Multi-Purpose SD Polyurea Grease

· John Deere Multi-Purpose HD Lithium Complex Grease

· John Deere Moly High Temperature EP Grease

If not using any of the preferred greases, be sure to use a general all-purpose grease with an NLGI grade No.2 rating.

Wet or high speed conditions may require use of a special-use grease. Contact your Servicing dealer for information.

Lubricating Tractor Grease Fittings

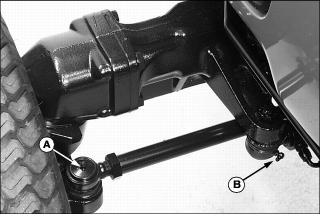

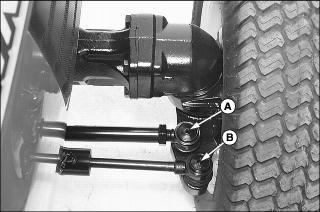

MFWD Model Tractors

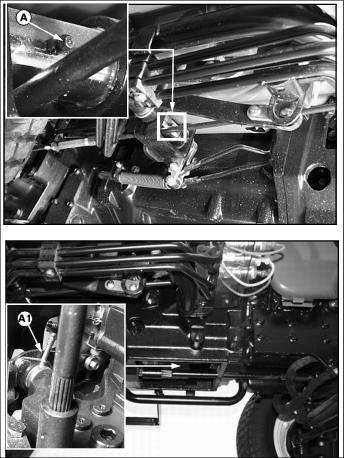

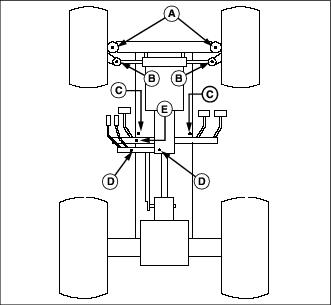

B - Left Steering Cylinder Ball Joint

B - Right Steering Cylinder Ball Joint

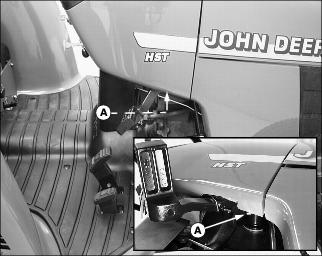

A - Upper Brake Pedal Tube (HST Models Only)

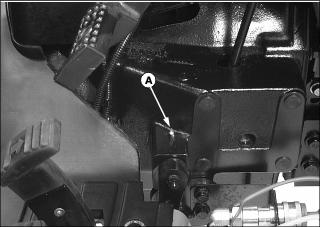

A - Lower Brake Pivot Tube-Left Side

A - Lower Brake Pedal Tube-Right Side

NOTE: Grease fitting (A) is located under the foot platform on the right side of the tractor. Grease fitting (A1) is located inside the clutch housing.

Model 4200 and 4300 2WD Tractors

NOTE: Bottom view of HST tractor shown in service lubrication diagram.

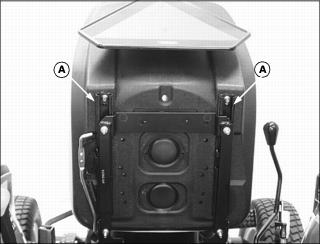

Lubricating Seat Slide Rails

2. Lubricate seat slide rails (A) with clean engine oil.

Lubricating 3-Point Hitch

· Lubricate lift link grease fittings (A) with a preferred John Deere grease or an equivalent.

· Lubricate ball joints (B) and draw bar (C) with clean engine oil.