Introduction

Safety Signs

Controls

Operating

Replacement Parts

Service Machine Safely

Service Interval Chart

Service Engine

Service Engine

Service Transmission

Service Steering & Brakes

Service Mower

Avoid Injury From Contacting Blades

Lubricating Mower Spindles (36-Inch Decks)

Lubricating Mower Spindles (48/54-Inch Decks)

Lubricating Deck Idler Arm (48/54-Inch Decks)

Replacing Clutch To Mower Deck Drive Belt (36-Inch Decks)

Replacing Mower Deck Timing Belt (36-Inch Decks)

Quick Check On Mower Deck Timing (36-Inch Decks)

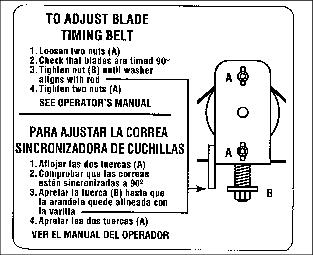

Adjusting Mower Deck Timing (36-Inch Decks)

Adjusting Timing Belt Tension (36-Inch Decks)

Level Mower Deck (Front-To-Rear) (36-Inch Decks)

Level Mower Deck (Side-To-Side) (36-Inch Decks)

Replacing Clutch To Mower Deck Drive Belt (48/54-Inch Decks)

Replacing Mower Deck Drive Belt (48/54-Inch Decks)

Level Mower Deck (Front-To-Rear) (48/54-Inch Decks)

Level Mower Deck (Side-To-Side) (48/54-Inch Decks)

Inspecting And Replacing Mower Blades

Service Electrical

Service Miscellaneous

Troubleshooting

Storing Machine

Assembly

Specifications

Warranty

Service Literature

Copyright© Deere & Company

Service Mower

Avoid Injury From Contacting Blades

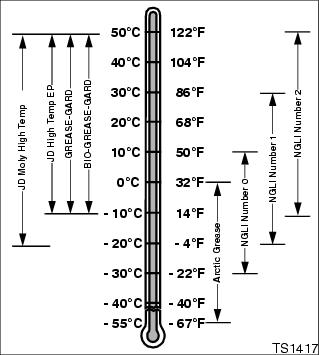

Grease

Use grease based on the expected air temperature range during the service interval.

The following greases are preferred:

· John Deere Moly High Temperature EP Grease.

· John Deere High Temperature EP Grease.

Other greases may be used are:

· SAE Multipurpose EP Grease with 3 to 5 percent molybdenum disulfide.

· Greases meeting Military Specification MIL-G-10924C may be used as arctic grease.

Lubricating Mower Spindles (36-Inch Decks)

· Lubricate at least every 25 hours of operation.

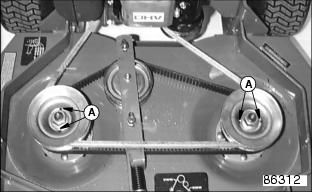

Lubricate both mower spindle grease fittings (A) with John Deere Moly High Temperature EP Grease or an equivalent.

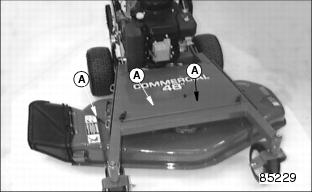

Lubricating Mower Spindles (48/54-Inch Decks)

· Lubricate at least every 25 hours of operation.

Lubricate all three mower spindle grease fittings (A) with John Deere Moly High Temperature EP Grease or an equivalent.

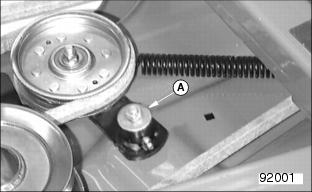

Lubricating Deck Idler Arm (48/54-Inch Decks)

· Lubricate at least every 100 hours of operation.

2. Loosen hardware and remove left belt cover.

3. Lubricate grease fitting (A) with John Deere Moly High Temperature EP Grease or an equivalent.

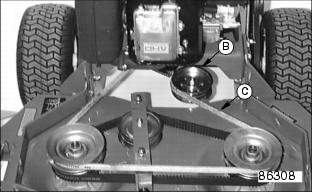

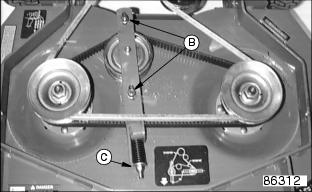

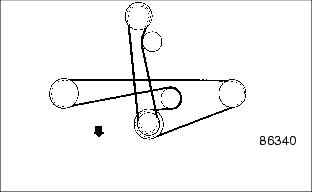

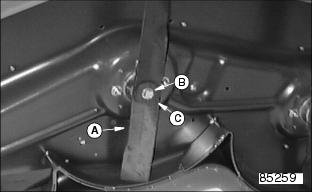

Replacing Clutch To Mower Deck Drive Belt (36-Inch Decks)

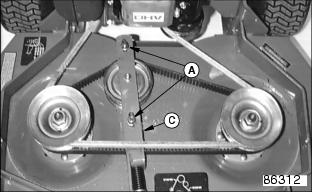

2. Pull spring loaded idler (B) to loosen belt tension.

3. Remove and replace clutch to mower deck drive belt (C).

4. Make sure drive belt is properly routed around the spring loaded idler (B) for proper belt tension.

5. If necessary, see label on mower deck.

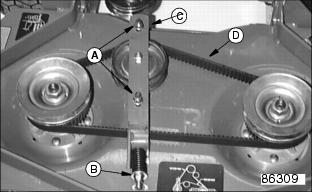

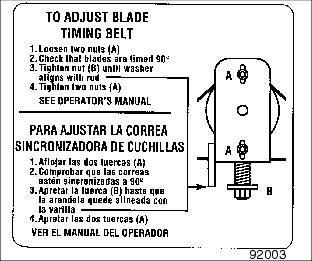

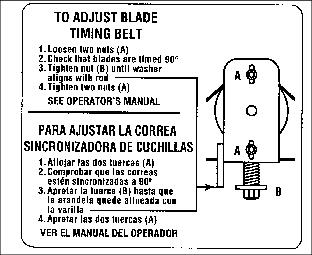

Replacing Mower Deck Timing Belt (36-Inch Decks)

1. Remove the clutch to mower deck drive belt. (See Replacing Clutch To Mower Deck Drive Belt (36-Inch Decks) in this Section.

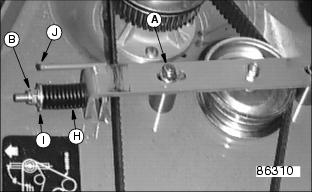

2. Loosen timing belt tension:

· Loosen locknut (B) to the ends of the threads.

· Tension arm (C) will loosen belt tension.

3. Remove two locknuts (A) and tension arm (C).

4. Remove old mower deck timing belt (D).

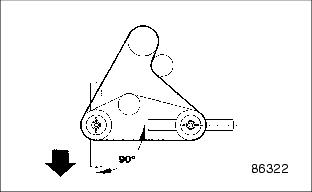

5. Position mower blades (E) and (F) 90° (G) from each other.

6. Install new mower deck timing belt (D).

7. Install tension arm. Install and turn two locknuts (A) down part way to allow movement of arm (C). Inspect tension arm (C), tension arm must be free to slide.

· Check that blades are still timed (90° from each other).

· Rotate blades to make sure they do not contact each other.

If necessary, see label on mower deck.

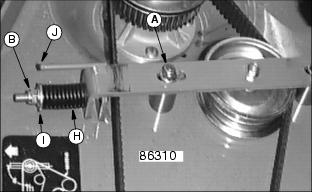

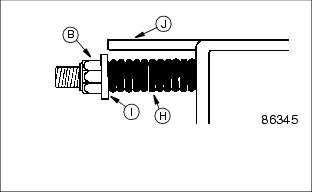

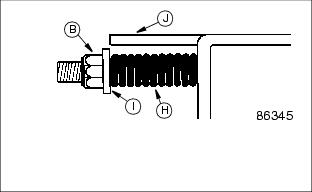

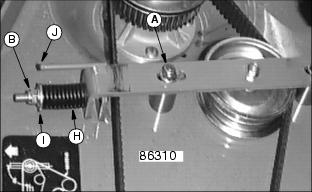

NOTE: Lock nuts (A) must be loose to allow movement of idler arm during adjustment of lock nut (B).

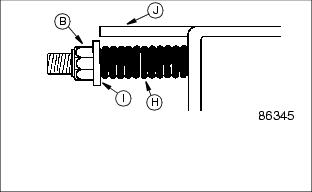

· Tighten lock nut (B) to compress spring (H). Tighten lock nut until the spring side of washer (I) is even with adjustment rod end (J).

NOTE: Locknuts (A) must be tightened to prevent idler movement during mower operation. If idler is free to move, blades will become out of time.

· Tighten both lock nuts (A) to approximately 55 N·m (40 lb-ft).

If necessary, see label on mower deck.

9. Install the clutch to mower deck drive belt. (See Replacing Clutch To Mower Deck Drive Belt (36-Inch Decks) in this Section)

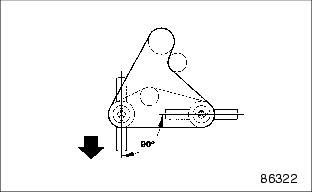

Quick Check On Mower Deck Timing (36-Inch Decks)

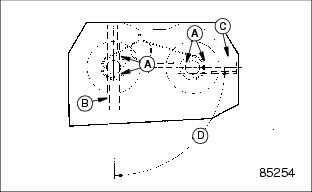

2. Note the position of the drain holes (A) in the spindle sheaves. These drain holes are in alignment with the mower blades.

3. A properly timed mower deck must have the mower blades (B) and (C) at 90° (D) from each other.

4. For a quick check on mower deck timing, sheave drain holes (A) should be approximately 90° from each other.

5. If necessary, adjust the mower deck timing. (See Adjusting Mower Deck Timing in this section)

NOTE: Due to mower blade over-lap, the mower blades will eventually collide if the timing belt is not adjusted on a regular basis.

If necessary, see Adjusting Timing Belt Tension (36-Inch Decks) in this section.

Adjusting Mower Deck Timing (36-Inch Decks)

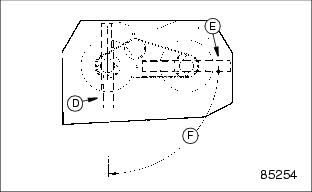

2. Loosen timing belt tension:

· Loosen locknut (B) to the ends of the threads.

· Tension arm (C) will loosen belt tension. Inspect tension arm (C). Tension arm must be free to slide.

3. Position mower blades (D) and (E) 90° (F) from each other. If necessary, reposition mower blades:

· Remove two lock nuts (A) and tension arm (C).

· Slip timing belt off of one sprocket.

· Install tension arm and two lock nuts. Tension arm must be free to slide.

· Check that blades are still timed (90° from each other).

· Rotate blades to make sure they do not contact each other.

NOTE: Lock nuts (A) must be loose to allow movement of idler arm during adjustment of lock nut (B).

· Tighten lock nut (B) to compress spring (H). Tighten lock nut until the spring side of washer (I) is even with adjustment rod end (J).

NOTE: Locknuts (A) must be tightened to prevent idler movement during mower operation. If idler is free to move, blades will become out of time.

· Tighten both lock nuts (A) to approximately 55 N·m (40 lb-ft).

If necessary, see label on mower deck.

Adjusting Timing Belt Tension (36-Inch Decks)

NOTE: Due to mower blade over-lap, the mower blades will eventually collide if the timing belt is not adjusted on a regular basis.

2. Check the position of the drain holes (A) in the spindle sheaves. These drain holes are in alignment with the mower blades. If drain holes are not perpendicular to each other, the mower blades will need to be repositioned, see Adjusting Mower Deck Timing (36-Inch Decks) in this section.

3. Loosen timing belt tension:

· Tension arm (C) will move due to spring force.

· Inspect tension arm. Tension arm must be free to slide under lock nuts (B).

NOTE: Lock nuts (A) must be loose to allow movement of idler arm during adjustment of lock nut (B).

· Tighten lock nut (B) to compress spring (H). Tighten lock nut until the spring side of washer (I) is even with adjustment rod end (J).

NOTE: Locknuts (A) must be tightened to prevent idler movement during mower operation. If idler is free to move, blades will become out of time.

· Tighten both lock nuts (A) to approximately 55 N·m (40 lb-ft).

If necessary, see label on mower deck.

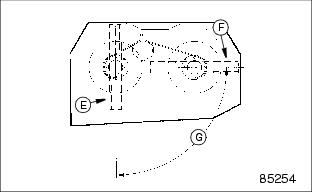

Level Mower Deck (Front-To-Rear) (36-Inch Decks)

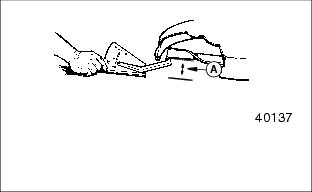

Blades may have sharp edges. Wear heavy gloves or use a rag to protect hands. |

NOTE: Before checking mower deck front to rear level, check mower deck for the correct combination of cut height adjustments. (See Adjusting Mower Deck Height (36-Inch Decks) in the Operating section.)

1. Park mower on a hard level surface.

2. Check tire pressure: 100-200 kPa (15-28 psi).

3. Position left mower blade in the straight ahead position.

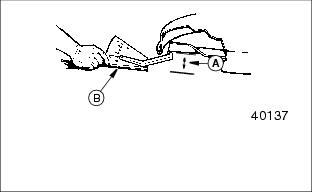

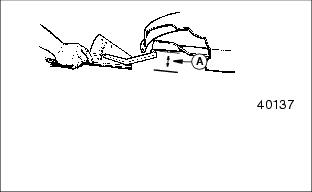

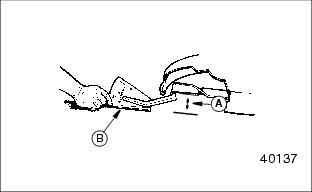

NOTE: Use a short ruler or leveling gauge (B). Order gauge from your John Deere dealer.

4. Measure from left front blade tip to floor. Turn blade 180° and measure from left rear tip to floor: Distance (A).

5. Repeat Steps 3 and 4 for right blade.

6. Distance (A) at rear of blade should be 3-6 mm (1/8-1/4 in.) more than Distance (A) at front of blade.

Level mower deck (front to rear) using mower deck attaching hardware or caster wheel washers.

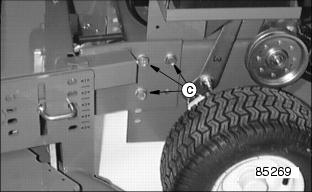

7. Mower deck attaching hardware:

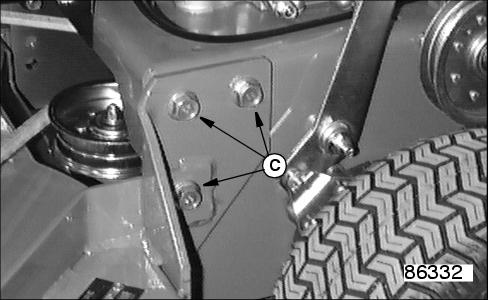

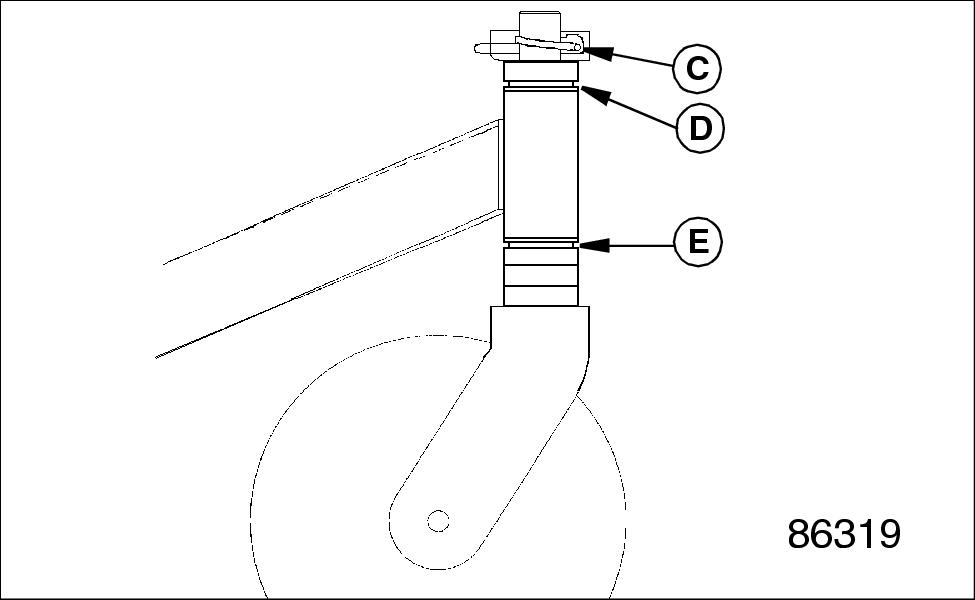

· Loosen mower deck to power unit attaching hardware (C).

· Level deck by rotating power unit with respect to the mower deck and tighten attaching hardware.

· Tighten locknuts to 140 N·m (105 lb-ft).

NOTE: Caster wheel washers should be used as a fine tune adjustment for front to rear leveling.

Always adjust left and right caster wheels equally, when adjusting level front to rear.

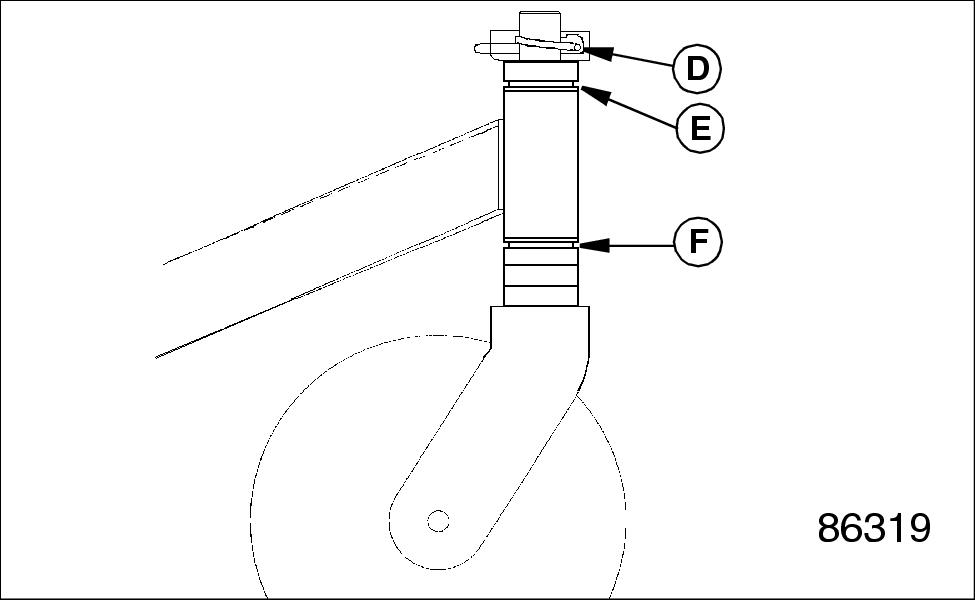

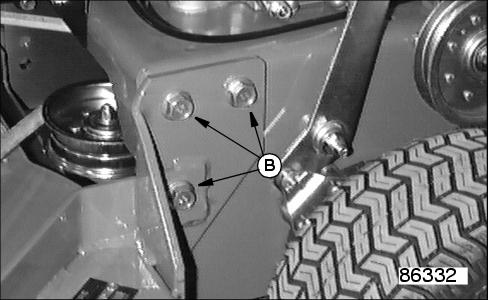

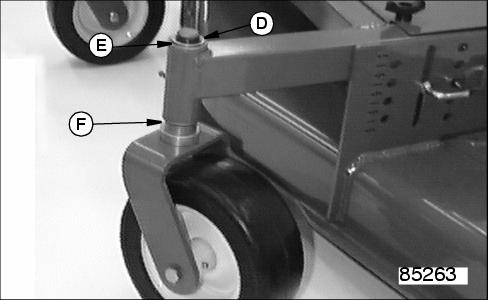

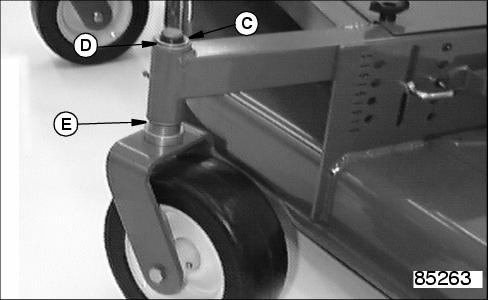

· Raise and block one side of mower 150 mm (6 in.).

· Move top washer (E) to bottom position to RAISE front of mower, OR move washer (F) from bottom to top to LOWER front of mower.

9. Check mower level. (Repeat Steps 2-6).

Level Mower Deck (Side-To-Side) (36-Inch Decks)

1. Park mower on a hard level surface.

2. Check tire pressure: 100-200 kPa (15-28 psi).

3. Turn right mower blade sideways.

4. Measure from right blade tip to floor. Distance (A).

5. Turn left blade sideways. Measure distance (A) from tip of blade.

6. Distance (A) should be the same on each side 3 mm (1/8 in.)

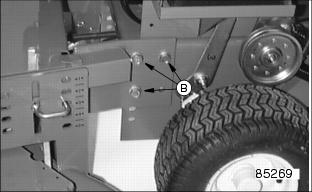

NOTE: When the mower deck is bolted to the power unit you have one solid frame. It will be necessary to loosen the mower deck attaching hardware in order to level the mower deck side to side.

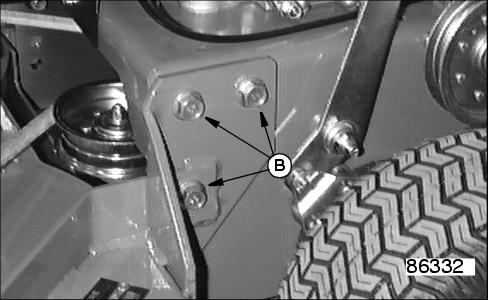

· Loosen mower deck to power unit attaching hardware (B).

8. Put blocks on both sides of mower deck to level mower blades.

9. Tighten mower deck to power unit attaching hardware (B):

· With the mower deck leveled (side-to-side), tighten attaching hardware.

· Tighten lock nuts to 140 N·m (105 lb-ft).

10. Remove blocks from mower deck.

11. Check mower level. Repeat Steps 2-6.

12. If one caster wheel is off the ground due to deck repositioning, adjust caster wheel washers:

· Raise and block one side of mower 150 mm (6 in.).

· Move top washer (D) to bottom position (E) to lower wheel.

13. Check mower level. (Repeat Steps 2-6).

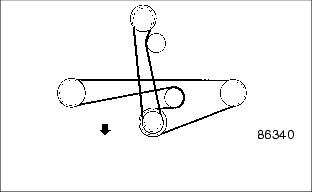

Replacing Clutch To Mower Deck Drive Belt (48/54-Inch Decks)

2. Pull spring loaded idler (B) to loosen belt tension.

3. Remove and replace clutch to mower deck drive belt (C).

4. Make sure drive belt is properly routed around the spring loaded idler (B) for proper belt tension.

5. If necessary, see label on mower deck.

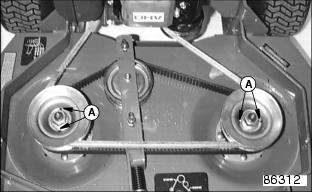

Replacing Mower Deck Drive Belt (48/54-Inch Decks)

1. Remove the clutch to mower deck drive belt. (See Replacing Clutch To Mower Deck Drive Belt (48/54-Inch Decks) in this Section.)

2. Remove left and right hand belt shields.

3. Pull spring loaded idler (A) to loosen belt tension.

4. Remove and replace mower deck drive belt (B).

5. Make sure drive belt is properly routed around the spring loaded idler (A) for proper belt tension.

6. If necessary, see label on mower deck.

7. Install left and right hand belt shields.

8. Install the clutch to mower deck drive belt. (See Replacing Clutch To Mower Deck Drive Belt (48/54-Inch Decks) in this Section.)

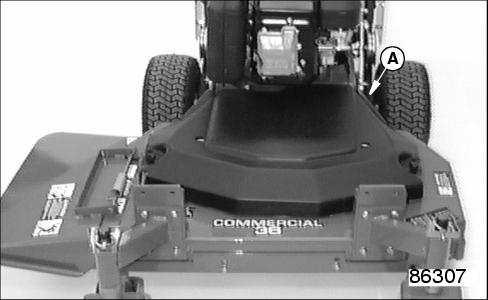

Level Mower Deck (Front-To-Rear) (48/54-Inch Decks)

Blades may have sharp edges. Wear heavy gloves or use a rag to protect hands. |

1. Park mower on a hard level surface.

2. Check tire pressure: 100-200 kPa (15-28 psi).

3. Position left mower blade in the straight ahead position.

NOTE: Use a short ruler or leveling gauge (B). Order gauge from your John Deere dealer.

4. Measure from left front blade tip to floor. Turn blade 180° and measure from left rear tip to floor: Distance (A).

5. Repeat Steps 3 and 4 for right blade.

6. Distance (A) at rear of blade should be 3-6 mm (1/8-1/4 in.) more than Distance (A) at front of blade.

Level mower deck (front-to-rear) using mower deck attaching hardware or caster wheel washers.

7. Mower deck attaching hardware:

· Loosen mower deck to power unit attaching hardware (C).

· Level deck by rotating power unit with respect to the mower deck and tighten attaching hardware.

· Tighten locknuts to 140 N·m (105 lb-ft).

NOTE: · Caster wheel washers should be used as a fine tune adjustment for front to rear leveling.

· Always adjust left and right caster wheels equally, when adjusting level front to rear.

· Raise and block one side of mower 150 mm (6 in.).

· Move top washer (E) to bottom position to RAISE front of mower, OR move washer (F) from bottom to top to LOWER front of mower.

9. Check mower level. (Repeat Steps 2-6).

Level Mower Deck (Side-To-Side) (48/54-Inch Decks)

1. Park mower on a hard level surface.

2. Check tire pressure: 100-200 kPa (15-28 psi).

3. Turn right mower blade sideways.

4. Measure from right blade tip to floor. Distance (A).

5. Turn left blade sideways. Measure distance (A) from tip of blade.

6. Distance (A) should be the same on each side 3 mm (1/8 in.)

NOTE: When the mower deck is bolted to the power unit you have one solid frame. It will be necessary to loosen the mower deck attaching hardware in order to level the mower deck side to side.

· Loosen mower deck to power unit attaching hardware (B).

8. Put blocks on both sides of mower deck to level mower blades.

9. Tighten mower deck to power unit attaching hardware (B).

· With the mower deck leveled (side-to-side), tighten attaching hardware.

· Tighten lock nuts to 140 N·m (105 lb-ft).

10. Remove blocks from mower deck.

11. Check mower level. Repeat Steps 2-6.

12. If one caster wheel is off the ground due to deck repositioning, Adjust caster wheel washers:

· Raise and block one side of mower 150 mm (6 in.).

· Move top washer (D) to bottom position (E) to lower wheel.

13. Check mower level. (Repeat Steps 2-8).

Inspecting And Replacing Mower Blades

1. Raise and block front of mower.

· Mower blades should be sharp and free of any damage.

· Replace mower blades as required.

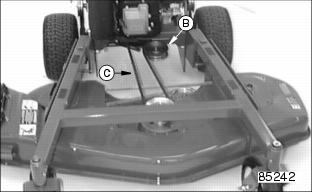

3. Remove and replace damaged blade(s):

· Remove blade bolt (B), washer (C) and blade (A). Discard any blade that has been damaged due to a serious impact.

· When you install new blade, put cup-side of washer (C) against blade.

· 48/54-Inch Deck: Tighten blade bolts to 68 N·m (50 lb-ft).

· 36-Inch Deck: Tighten blade bolts to 81 N·m (60 lb-ft). If new mower blades are installed on a 36-Inch Deck, see Adjusting Mower Deck Timing (36-Inch Decks) in this section.

4. Remove supports and lower mower.

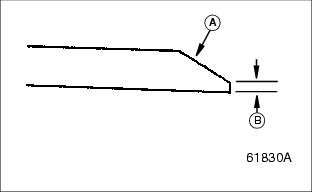

Sharpening Blades

· Sharpen blades with grinder, hand file or electric blade sharpener.

· Keep original bevel (A) when you grind.

· Blade should have 0.40 mm (1/64 in.) cutting edge (B).

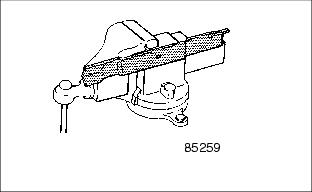

Balancing Blades

2. Put blade on nail in vise or on vertical wall stud. Turn blade to horizontal position.

3. If blade is not balanced, heavy end of blade will drop.

4. Grind bevel of heavy end. Do not change bevel.

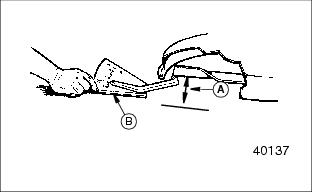

Checking Mower Blades

· Measure from blade tip to floor-Distance (A).

NOTE: Use leveling gauge (B) or short ruler. Order leveling gauge from your John Deere dealer.

· Measure opposite blade tip for Distance (A).

· Difference between two measurements (A) must not be more than 3 mm (1/8 in.)

3. Replace blade if needed. If new mower blades are installed on a 36-Inch Mower, see Adjusting Mower Deck Timing (36-Inch Decks) in this section.