Introduction

Safety Signs

Controls

Operating

Replacement Parts

Service Machine Safely

Service Interval Chart

Service Engine

Service Engine

Service Transmission

Service Steering & Brakes

Service Mower

Service Electrical

Service Miscellaneous

Troubleshooting

Storing Machine

Assembly

Specifications

Warranty

Service Literature

CopyrightŠ Deere & Company

Service Miscellaneous

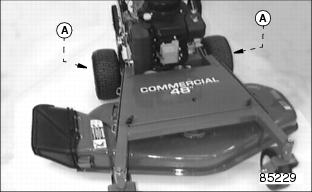

Checking Tire Pressure

2. Check tire pressure with an accurate gauge.

NOTE: Tire Sealant may be necessary when you operate in rough conditions. (See your John Deere dealer for TY6346 Tire Sealant.)

Adjusting Tire Pressure

1. Drive mower forward on level, flat ground: Do not use service brake levers.

2. Mower should not go to left or right more than 0.3 m (1 ft.) in 15 m (50 ft.) of travel.

3. Adjust tire pressure if necessary:

ˇ If mower wanders to left too much, add air to left drive tire or let some air out of right tire.

ˇ If mower wanders to right too much, add air to right drive tire or let some air out of left tire.

ˇ Pressure in drive tires does not have to be equal, but should be between pressures shown on chart.

Lubricating Drive Wheels

ˇ Lubricate at least every 25 hours of operation.

Lubricate both drive wheels grease fittings (A) with John Deere Moly High Temperature EP Grease or an equivalent.

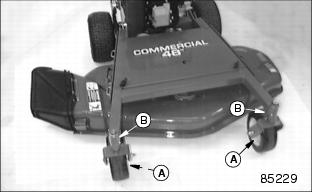

Lubricating Caster Wheels

ˇ Lubricate at least every 25 hours of operation.

Lubricate both caster wheel grease fittings (A) and caster wheel spindles (B) with John Deere Moly High Temperature EP Grease or an equivalent.

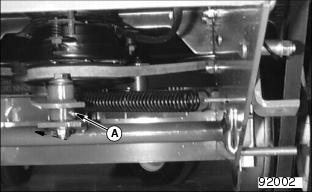

Lubricating Primary Idler Arm

NOTE: Access to primary idler for lubrication is from rear below engine platform.

ˇ Lubricate at least every 100 hours of operation.

Lubricate grease fitting (A) with John Deere Moly High Temperature EP Grease or an equivalent.

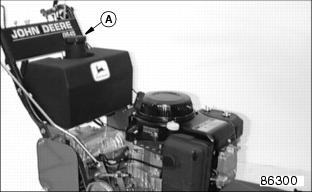

Fuel

IMPORTANT: Avoid damage! Avoid spilling fuel. Fuel can damage plastic and painted surfaces. DO NOT mix oil with gasoline. Unleaded gasoline with an octane rating of 87 or higher is recommended. |

ˇ Use only clean, fresh, unleaded regular grade gasoline.

ˇ Remove any trash from top of fuel tank drain area.

ˇ Use summer blended fuel for warm weather operation and winter blended fuel for cold weather.

ˇ Never use fuel that is stale or has been stored for a long period of time. Warm Weather: Maximum 60 days - Cold Weather: Maximum of 90 days.

ˇ Fill fuel tank at the end of each day's operation. This helps to keep condensation out of fuel tank.

Oxygenates (either ethanol or MTBE) are added to the gasoline. If you use the oxygenated fuel be sure it is unleaded and meets the minimum octane rating requirement.

The following are the EPA approved percentages of fuel oxygenates:

ˇ ETHANOL (Ethyl or Grain Alcohol): You may use gasoline containing up to 10 percent ethanol by volume.

ˇ MTBE (Methyl Tertiary Butyl Ether): You may use gasoline containing up to 15 percent MTBE by volume.

ˇ METHANOL (Methyl or Wood Alcohol): You may use gasoline containing up to 5 percent methanol by volume, as long as it also contains cosolvents and corrosion inhibitors to protect the fuel system. Gasoline containing more than 5 percent methanol by volume may cause starting and/or performance problems. It may also damage metal, rubber, and plastic parts of your fuel system.

Filling Fuel Tank

Fill fuel tank at the end of each day's operation to prevent condensation and freezing during cold weather.

1. STOP engine. If engine is hot let it cool several minutes before you add fuel.

2. Remove any trash from area around fuel tank.