Compact Utility Tractor with Gear Transmission

INTRODUCTION

SAFETY SIGNS

CONTROLS

OPERATING MACHINE

REPLACEMENT PARTS

SERVICE MACHINE SAFELY

SERVICE INTERVAL CHART

SERVICE ENGINE

SERVICE TRANSMISSION

SERVICE ELECTRICAL

SERVICE MISCELLANEOUS

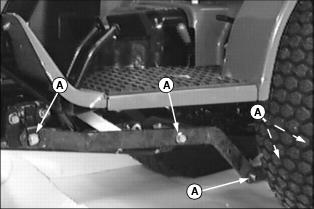

Lubricating Tractor Grease Fittings

Lubricating Mower Deck Lift Linkage

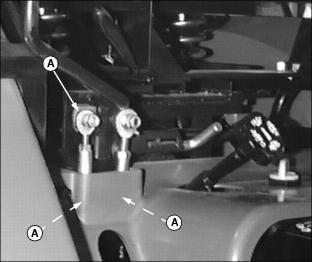

Lubricating Hydraulic Selective Control Valve (SCV) Linkage

TROUBLESHOOTING

STORING MACHINE

ASSEMBLY

SPECIFICATIONS

WARRANTY

JOHN DEERE SERVICE LITERATURE

QUALITY DOESN'T END WHEN YOU INVEST IN A DEERE

Copyright© Deere & Company

SERVICE MISCELLANEOUS

GREASE

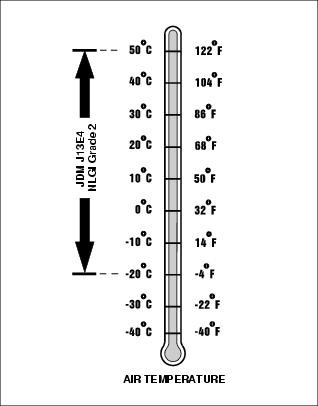

Use the following gear grease based on the air temperature range. Operating outside of the recommended grease air temperature range may cause premature failure.

IMPORTANT: Avoid damage! ONLY use a quality grease in this application. DO NOT mix any other greases in this application. DO NOT use any BIO-GREASE in this application. |

The following John Deere gear grease is PREFERRED:

· NON-CLAY HIGH-TEMPERATURE EP GREASE®-JDM J13E4, NLGI Grade 2

Other greases may be used if above John Deere greases are not available, provided they meet the following compatibility specifications only:

· John Deere Standard JDM J13E4, NLGI Grade 2

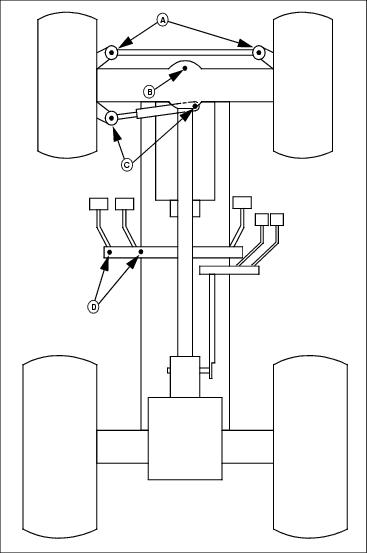

Lubricating Tractor Grease Fittings

C - Power Steering Cylinder (2 Fittings)

D - Turn Brake Pedals (2 Fittings)

Lubricating 3-Point Hitch

Lubricating Seat Side Rails

Lubricating Mower Deck Lift Linkage

Lubricating Hydraulic Selective Control Valve (SCV) Linkage

Diesel Fuel Specifications

In general, diesel fuels are blended to satisfy the low air temperature requirements of the geographical area in which they are sold.

Diesel fuel is usually specified to ASTM D975 and sold as either Grade 1 for cold air temperatures or Grade 2 for warm air temperatures.

If diesel fuels being supplied in your area DO NOT meet any of the above specifications, use diesel fuels with the following equivalent properties:

Bio-Diesel Fuels with bio-degradable properties that meet specification DIN 51606 or equivalent may be used.

Consult your local diesel fuel distributor for properties of the diesel fuel available in your area

Lubricity

Diesel fuel must have adequate lubricity to ensure proper operation and durability of fuel injection system components. Fuel lubricity should pass a minimum of 3300 gram load level as measured by the BOCLE scuffing test.

Storage

It is recommended that diesel fuel be stored ONLY in a clean, approved POLYETHYLENE PLASTIC container WITHOUT any metal screen or filter. This will help prevent any accidental sparks from occurring. Store fuel in an area that is well ventilated to prevent possible igniting of fumes by an open flame or spark, this includes any appliance with a pilot light.

Keep fuel in a safe, protected area and in a clean, properly marked ("DIESEL FUEL") container. DO NOT use de-icers to attempt to remove water from fuel. DO NOT use de-icers to attempt to remove water from fuel. DO NOT depend on fuel filters to remove water from fuel. It is recommended that a water separator be installed in the storage tank outlet. BE SURE to properly discard unstable or contaminated diesel fuel and/or their containers when necessary.

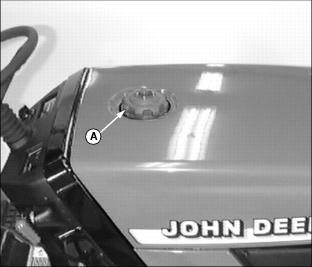

Filling the Fuel Tank

IMPORTANT: Avoid damage! Avoid spilling fuel. Fuel can damage plastic and painted surfaces. Fuel tank capacity is approximately 22.0 L (5.8 gal). |

2. Fill fuel tank at end of each day's operation to prevent condensation in fuel tank as moist air cools.

3. Fill fuel tank when fuel gauge shows 1/4 or less fuel in tank.

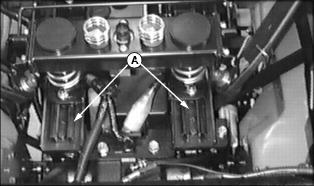

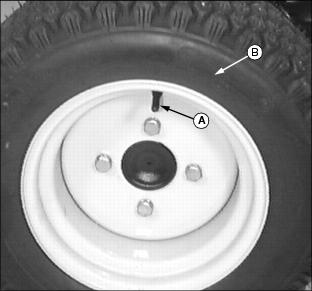

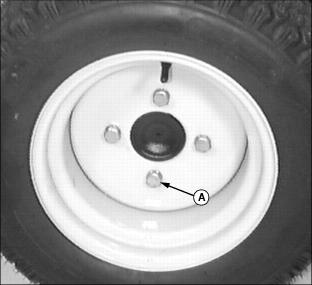

Checking Tire Pressure

IMPORTANT: Avoid damage! If the tire is liquid filled always keep the valve stem (A) at the top of the tire when checking tire pressure. This prevents liquid from escaping through the valve stem. |

2. Check tire pressure with an accurate gauge.

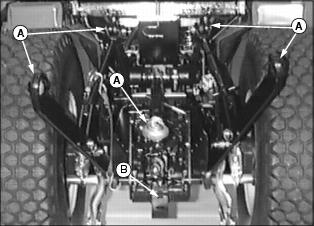

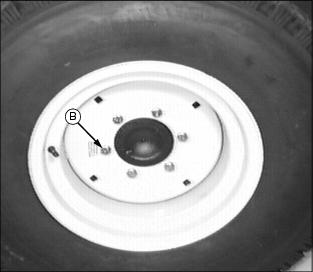

Checking Wheel Bolt Torque

1. Tighten front wheel bolts (A) sequentially to 147 N·m (108 lb-ft)

2. Tighten rear wheel bolts (B) sequentially to 98 N·m (72 lb-ft)