Introduction

Safety Signs

Controls

Operating

Replacement Parts

Service Machine Safely

Service Interval Chart

Service

Troubleshooting

Storing Machine

Assembly

Install and Adjust Discharge Chute

Install and Adjust Discharge Chute Crank

Connect And Adjust Chute Deflector Cable

Install And Check Auger Brake / Drive Cable

Connect And Adjust Traction Drive Cable

Specifications

Warranty

John Deere Quality Statement

CopyrightŠ Deere & Company

Assembly

Identify Snowblower Parts

Bag Of Parts

Add Engine Oil

NOTE: Remind customer to change oil after first two operating hours.

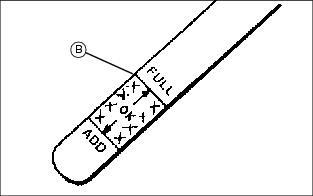

2. Add engine oil to bring level to the FULL mark (B) on dipstick. (See Engine Oil in this section for correct oil.):

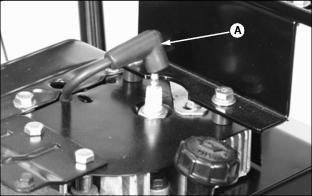

ˇ Add oil through dipstick tube (A).

Approximate crankcase capacity:

3. Install and tighten dipstick.

Connect Spark Plug Wire

1. Connect spark plug wire (A).

Install and Adjust Discharge Chute

1. Apply a liberal amount of grease between auger housing and discharge chute. (See Lubricating Discharge Chute in the Service section.)

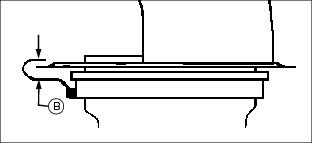

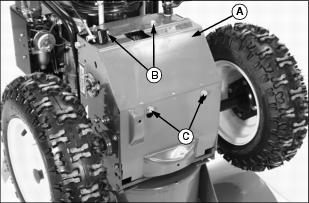

2. Install discharge chute (A) and attaching hardware (D). Discharge chute must be under chute retainer (B).

ˇ (2) Cap Screws, 5/16 x 1-1/4 in.

3. Adjust discharge chute - straightness:

ˇ Adjust discharge chute and attaching bracket until chute is sitting square on the auger housing.

4. Adjust discharge chute - height:

ˇ Loosen height adjusting hardware (E).

ˇ Adjust discharge chute until chute is located in the middle of the chute retainer (B).

Install Handle Bars

NOTE: On some units it may be easier to connect the Auger Brake / Drive Cable prior to installing the handle bars. See Install Auger Brake / Drive Cable in this section.

1. Locate handle bar assembly onto blower assembly.

2. On right side of unit, install attaching hardware (A) on blower assembly studs. Do not tighten nuts until hardware on left hand side is installed.

3. On left side of unit, install attaching hardware (B).

4. Tighten cap screws (B) and nuts (A).

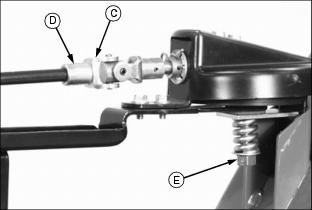

Install and Adjust Discharge Chute Crank

1. Install discharge chute crank:

ˇ Install chute crank (A) through bracket (B), hole in console and into gearbox universal joint (C).

ˇ Align cross drilled hole in chute crank with cross drilled hole in gearbox universal joint.

ˇ Install roll pin (D) to retain chute crank.

2. Adjust discharge chute crank - tightness:

ˇ Operate chute crank. Crank should be tight enough so it will not move from engine vibration, but should loose enough to operate smoothly.

ˇ If chute crank is too loose, tighten nut (E).

ˇ If chute crank is too tight, loosen nut (E).

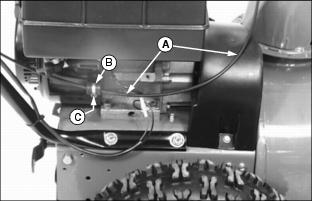

Connect Headlight Wiring

1. Connect ground wire (A) to front engine bolt.

2. Connect engine lead to mating connector (B).

Connect And Adjust Chute Deflector Cable

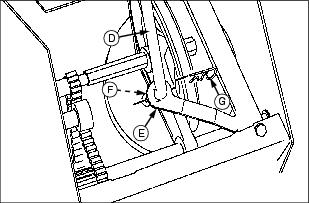

1. Route chute deflector cable (A) through clamp (B).

2. Locate and remove engine shroud bolt (C) on lower left side of engine.

3. Secure clamp with engine shroud bolt. Install and tighten bolt.

4. Route chute deflector cable (A) along right side of engine and up the left side of the discharge chute.

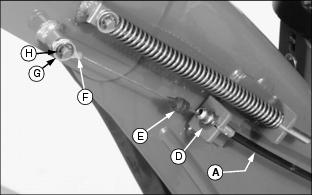

5. Attach cable to discharge chute with large external E-Ring (D). Make sure rubber boot (E) is over the cable opening. This will prevent water from entering the cable and freezing.

6. Attach cable end (F) to the chute deflector using a 1/4 inch flat washer and the small external E-Ring.

Adjust Chute Deflector Lever

ˇ Operate chute deflector lever. Lever should be tight enough so it will not move from engine vibration, but it should be loose enough to operate smoothly.

ˇ If lever is too loose, tighten nut (I).

ˇ If lever is too tight, loosen nut (I).

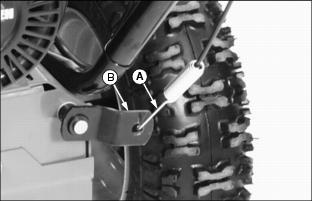

Install And Check Auger Brake / Drive Cable

1. Connect the auger brake / drive cable (A) to the auger drive linkage (B).

Check Auger Brake / Drive Cable

1. Remove two cap screws (C) to remove belt cover (D).

2. Check clearance between brake pad (C) and auger drive belt (D):

NOTE: When the auger drive cable has slack in it; that means maximum spring force is be applied to the brake arm.

ˇ With auger drive lever released, the brake pad (C) must contact auger drive belt.

Connect And Adjust Traction Drive Cable

1. Park snowblower on a hard, smooth surface.

2. Tip machine forward onto housing (A).

3. Connect traction drive cable:

ˇ Pull cable(C) tight and install in cable retainer (D).

ˇ Tighten set screw to retain cable.

Adjust Traction Drive Cable

1. With the traction drive lever disengaged, turn drive wheels by hand.

2. Tighten adjusting nut (E) until wheels begin to drag.

3. Engage and release traction clutch lever to align clutch linkage.

4. Repeat procedure as necessary.

5. When wheel drag is obtained with linkage alignment, loosen adjustment nut (E) a full three times. Drive wheels will then turn freely.

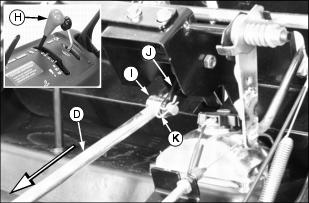

Install And Adjust Shift Rod

1. Remove two bolts (B) and loosen two bolts (C) to remove access panel (A).

2. Remove quick pull pin (G) and flat washer from shift rod (D).

IMPORTANT: Avoid damage! To prevent damage to the Friction Disk Wheel, the quick pull pin (G) must be installed as shown. This will prevent the open ends of the pin from contacting the rubber disc. |

3. Connect shift rod (D) to internal shift linkage (E) and secure with flat washer (F) and quick pull pin (G). Install quick pull pin with open ends of pin pointing away from the friction disk wheel.

4. Move shift lever (H) to the "6" (6th gear) position.

5. Remove quick pull pin (K) from shift rod (D).

6. Push shift rod (D) into housing as far as it will go and hold it in this position until rod adjustment is made.

7. Turn adjusting link (I) until stud aligns with hole in shift linkage (J).

IMPORTANT: Avoid damage! To prevent damage to the Headlight Housing, the quick pull pin (K) must be installed as shown. This will prevent the quick pull pin from contacting the headlight. |

8. Install shift rod adjusting link into shift lever linkage and install quick pull pin (K).

9. Install access panel (A) and hardware.

Check Auger Gearbox Oil Level

ˇ Fluid level should be at oil fill plug.

ˇ If necessary, add fluid. (See Gear Oil in the Service section.)

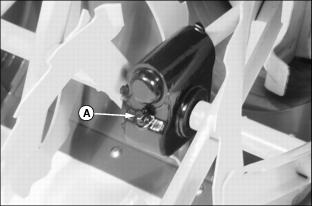

Checking Tire Pressure

Tire pressure has been increased for shipping purposes. Check tire pressure (A) with an accurate gauge. Tire pressure should be:

ˇ 828D - 138 kPa (20 psi) maximum.

ˇ 1032D - 96 kPa (14 psi) maximum.

Extra Auger Drive Shear Bolts

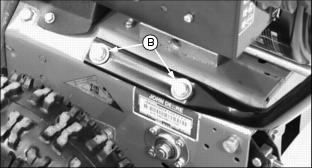

Two extra auger drive shear bolts (A) are included and attached to this unit.

Remind customer to remove extra shear bolts and to store in a safe place.