Introduction

Product Identification

Safety

Operating

Avoid Damage to Plastic and Painted Surfaces

Adjusting Mower Level (Side-to-Side)

Adjusting Mower Level (Front-to-Rear)

Testing Reverse Implement Option (RIO)

Using Indicator Lights and Hour Meter

Using Reverse Implement Option (RIO)

Pushing Machine (Using Free-Wheeling Lever)

Unplugging Mower or Optional Bagger

Transporting Machine on Trailer

Replacement Parts

Service Intervals

Service Lubrication

Service Engine

Service Transmission

Service Mower

Service Electrical

Service Miscellaneous

Troubleshooting

Storage

Assembly

Specifications

Warranty

John Deere Quality Statement

Service Record

Operating

Engine Break-In

Poor engine performance can result from improper break-in or incomplete break-in. Break-in is period of initial run time that seats piston rings to cylinder wall.

New engines need to be run hard, under varying loads for at least five hours and may not be completely broken-in until after 50 hours. Follow these guidelines:

· Run engine at full throttle during operation. Use partial throttle only for 30-60 seconds to warm a cold engine.

· Run engine under load by mowing, blowing snow, etc.

· Check oil and coolant (if equipped) levels often. Top off as necessary.

· Follow break-in service intervals.

Engine may show these symptoms during break-in:

· Excess exhaust smoke at startup and during operation.

· Slight surging at full throttle when not under load.

Daily Operating Checklist

o Check transmission oil level.

o Remove grass and debris from machine.

o Check area below machine for leaks.

Avoid Damage to Plastic and Painted Surfaces

· Do not wipe plastic parts unless rinsed first.

· Insect repellent spray may damage plastic and painted surfaces. Do not spray insect repellent near machine.

· Be careful not to spill fuel on machine. Fuel may damage surface. Wipe up spilled fuel immediately.

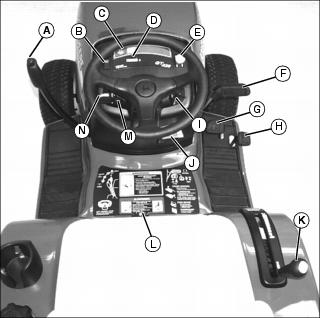

Operator Station Controls

Miscellaneous Controls

Adjusting Seat

Adjusting Seat Position

2. Slide seat forward or rearward to desired position.

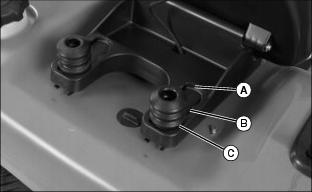

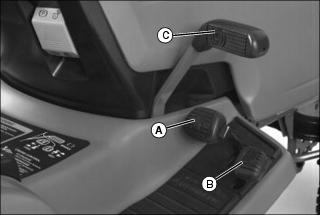

Adjusting Ride Comfort

IMPORTANT: Avoid damage! To prevent damage to seat switch and seat base, do not operate without suspension coils in place. |

2. Rotate suspension coils into desired position:

· Move coils to front position (A) for softest ride.

· Move coils to middle position (B) for average ride.

· Move coils to rear position (C) for firm ride.

NOTE: Additional suspension coils can be installed for extra support. See your John Deere dealer.

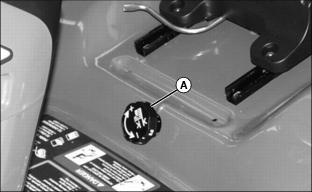

Adjusting Cutting Height

NOTE: Cutting height can be adjusted from approximately 25-100 mm (1-4 in.). Cut height is approximately 100 mm (4 in.) when lift lever is in transport position.

Mower must be raised completely before turning height control knob.

1. Park machine safely. (See Parking Safely in Safety section.)

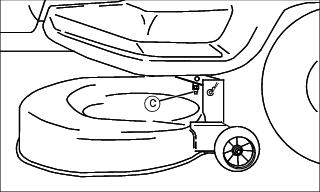

2. Raise mower deck completely.

3. Turn mower height control knob (A) to desired cutting height. Mower will be at set cutting height when lowered.

Adjusting Rear Wheel Spacing

NOTE: Wheel spacing is set narrow from factory. Narrow spacing provides overall tire width of 99.1 cm (39.0 in.). Wide spacing provides overall tire width of 105.4 cm (41.5 in.).

Rear wheels cannot be mounted in wide position if using 48C mower.

1. Park machine safely. (See Parking Safely in Safety section.)

2. Place blocks at front and rear of front tires.

4. Raise rear of machine with a safe lifting device so rear wheels are slightly off of ground.

6. Remove rear wheels and install for desired spacing:

Turf Tires

· Narrow Spacing - Install each wheel with valve stem to outside.

· Wide Spacing - Install each wheel with valve stem to inside.

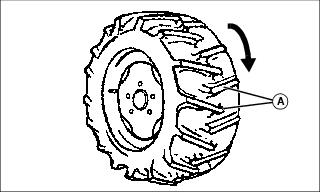

Bar Tires

· Narrow or Wide Spacing - Move each wheel to opposite side of machine with traction bars (A) pointing forward.

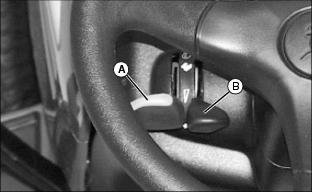

Adjusting Mower Wheels

1. Park machine safely. (See Parking Safely in Safety section.)

2. Inflate tires to correct pressure.

3. Put lift lever in transport position.

5. Lower mower to cutting position.

6. Measure distance between mower wheels and ground surface:

· 42C Mower - All wheels should be 3-9 mm (1/8-3/8 in.) from ground.

· 48C and 54C Mower - All wheels should be 6-13 mm (1/4-1/2 in.) from ground.

7. Adjust mower wheels to correct height:

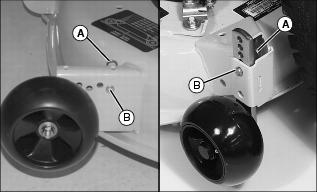

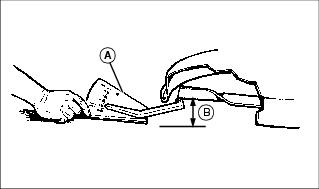

Picture Note: 42C shown left, 48C shown right.

· 42C and 48C Mower - Remove spring locking pin (A) and drilled pin (B). Move wheel to proper hole position. Install pins.

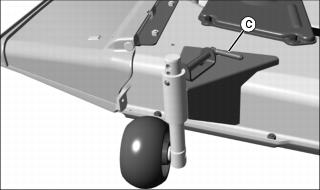

· 54C Mower - Pull pin (C) outward and move wheel to proper hole position. Release pin to lock wheel in position.

Adjusting Mower Level (Side-to-Side)

NOTE: Mower wheels should not contact ground when leveling deck.

1. Park machine safely. (See Parking Safely in Safety section.)

2. Inflate tires to correct pressure.

3. Adjust cutting height to 50 mm (2 in.).

4. Lower mower to cutting position.

NOTE: Difference between blade measurements must not be more than 3 mm (1/8 in.).

5. Turn left blade parallel to axle and complete measurement. Hold drive belt and turn right blade parallel to machine axle and complete measurements.

Picture Note: A convenient leveling gauge (A) is available from your John Deere dealer.

6. Measure from each outside blade tip (B) to level surface.

NOTE: Cutting height can closely match knob setting by adjusting lift links on both sides of deck.

Deck will not lock in transport position if adjusted too high.

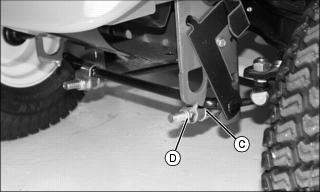

Picture Note: Left side shown.

7. Adjust lift links, turn nut (C):

· Clockwise to raise left side of mower.

· Counterclockwise to lower left side of mower.

Adjusting Mower Level (Front-to-Rear)

NOTE: Mower wheels should not contact ground during leveling.

1. Park machine safely. (See Parking Safely in Safety section.)

2. Inflate tires to correct pressure.

3. Adjust cutting height to 50 mm (2 in.).

4. Lower mower deck completely.

5. Turn right blade so blade tip points straight forward.

Picture Note: A convenient leveling gauge (A) is available from your John Deere dealer.

6. Measure distance (B) from blade tip to level surface:

· 42C Mower - Front blade tip must be 3-9 mm (1/8-3/8 in.) lower than rear blade tip.

· 48C and 54C Mower - Front blade tip must be 3-6 mm (1/8-1/4 in.) lower than rear blade tip.

7. Adjust front-to-rear mower level if necessary:

a. Loosen rear nut (C) on each side of front lift rod.

b. Turn front nut (D) on each side clockwise to raise front of mower or counterclockwise to lower it.

c. Tighten rear nuts after adjustment is complete.

8. Check adjustment by measuring blade tips again.

Testing Safety Systems

Use following procedures to check for normal operation of machine.

If there is a malfunction during one of these procedures, Do not operate machine. See your John Deere dealer for service.

Perform these tests in a clear open area. Keep bystanders away.

Testing Park Brake Switch

1. Park machine safely. (See Parking Safely in Safety section.)

Testing Park Brake

1. Park machine safely. (See Parking Safely in Safety section.)

3. Try to push machine manually.

Testing PTO Switch

1. Park machine safely. (See Parking Safely in Safety section.)

Testing Seat Switch

Test 1

2. Move throttle lever to maximum speed position.

5. Raise up off seat. Do not get off machine.

Test 2

4. Raise up off seat. Do not get off machine.

Test 3

3. Raise up off seat. Do not get off machine.

Testing Reverse Implement Option (RIO)

1. Park machine safely. (See Parking Safely in Safety section.)

3. Engage PTO to start attachment.

4. Look behind machine to be sure there are no bystanders.

5. Begin reverse travel by depressing reverse foot pedal.

Using Park Brake

Always lock park brake and remove key before leaving machine unattended. |

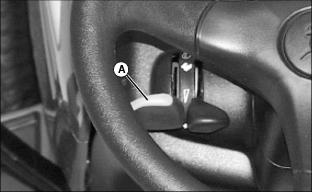

Locking Park Brake

1. Push and hold down brake pedal (A).

2. Pull up park brake lever (B) to lock park brake.

3. Release brake pedal. Pedal should stay down and park brake lever should stay up in locked position.

Unlocking Park Brake

1. Push and hold down brake pedal (A).

2. Push down park brake lever (B) to unlock park brake.

3. Release brake pedal. Pedal should come up to operating position.

Using Headlights

· Press at top of light switch (A) to turn headlights on.

· Press at bottom of light switch (A) to turn headlights off.

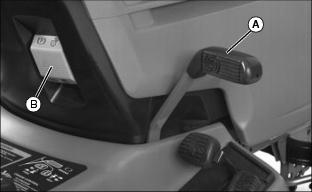

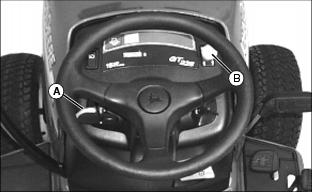

Using Indicator Lights and Hour Meter

A - Oil Pressure Indicator - will come on when key is turned to run position. Indicator should go out when engine is started. If indicator comes on during operation, engine oil pressure is too low. Stop engine and perform appropriate service.

B - Battery Discharge Indicator - will come on when key is turned to run position. Indicator should remain on during starting cycle and then go off. Indicator may remain on at low idle or if battery charge is low and PTO and headlights are turned on. If indicator comes on during normal operation, stop engine and perform appropriate service.

C - Hour Meter - shows number of hours engine has run. Hour meter will run with engine off when key is in run position with operator's seat occupied or park brake locked with PTO off. Use hour meter to determine when machine has reached recommended service intervals.

Checking Fuel Level

Check fuel level in fuel tank (A).

Starting Engine

NOTE: Engine will not start unless park brake is applied and PTO is disengaged.

2. Make sure PTO switch is disengaged.

· If engine is cold, move throttle lever (A) between half throttle and fast throttle positions.

· If engine is warm, move throttle lever (A) to slow throttle position.

· If engine is cold, push and hold choke lever (B) in full choke position.

· If engine is warm, push and hold choke lever (B) in half choke position; or do not use, depending on engine temperature.

6. Turn key to run position (C).

7. Make sure oil pressure and battery discharge indicators illuminate.

IMPORTANT: Avoid damage! Starter may be damaged if operated longer than 20 seconds at a time. Wait two minutes between starting intervals if engine does not start immediately. |

8. Turn key to start position (D) for no longer than five seconds.

9. Release key to run position (C) and release choke lever when engine starts. If engine does not start:

b. Hold choke lever in appropriate position.

c. Turn key to start position again for no longer than five seconds. Release key and choke lever when engine starts.

d. Repeat procedure if necessary.

IMPORTANT: Avoid damage! Unnecessary engine idling can cause engine overheating, carbon build-up, and poor performance. |

10. Run engine at half throttle for 30-60 seconds to allow warm-up before operating.

Stopping Engine

2. Move throttle lever (A) to slow position. Allow engine to idle for several seconds.

3. Turn key to stop position (B).

Using Travel Controls

Forward Travel

3. Push down slowly on forward pedal (A) until desired travel speed is obtained.

4. Release forward pedal and machine will automatically return to neutral and stop.

Reverse Travel

NOTE: Any operating attachment will stop as reverse foot pedal is depressed with attachment engaged.

2. Push PTO knob down to off position to disengage attachment.

3. Look behind machine to be sure there are no bystanders near.

4. Push down slowly on reverse pedal (B).

Stopping

1. Release either travel pedal, machine will automatically return to neutral and stop.

Using Reverse Implement Option (RIO)

NOTE: Operating mower while backing up is strongly discouraged. Reverse Implement Option should be used only when operating another attachment or when operator deems it necessary to reposition machine with mower engaged.

1. Stop machine. Allow attachment to run.

2. Look behind machine to be sure there are no bystanders.

3. Lift PTO switch (A) past PTO engagement position while depressing reverse foot pedal slightly.

NOTE: If attachment stops while positioning machine, return PTO switch to off position. Repeat this procedure from beginning.

4. As machine begins to move backward, release PTO switch and position machine.

5. Resume forward travel. Attachment should continue operating.

6. Repeat procedure to position machine again.

Using Cruise Control

Do not use cruise control when going down hills. Machine speed will increase. Operate machine in a large, open area to learn how cruise control works. |

Use cruise control to maintain travel speed without having to hold forward travel pedal down. Cruise control operates only for forward travel.

Engaging Cruise Control

1. Put cruise control lever (A) in off position.

2. Move cruise control lever forward to slow speed position to begin forward machine travel.

3. Continue to move lever forward to increase speed.

4. Release lever when desired cruise speed is reached.

Disengaging Cruise Control

· Move cruise control lever (A) completely rearward to off position, or

· Push down park brake pedal (B), then move cruise control lever (A) completely rearward to off position.

Using PTO (Power Take-Off)

NOTE: PTO operation will stop if reverse pedal is depressed. Understand Reverse Implement Option (RIO) system before operating PTO.

1. Start engine. If necessary, allow engine to warm up before operating PTO.

NOTE: Always operate at maximum throttle speed when PTO is engaged.

2. Move throttle lever (A) to fast position.

3. Move PTO switch (B) to desired position:

· Engage PTO - Lift up on switch to "l" position.

· Disengage PTO - Push down on switch to "O" position.

· Maintain PTO engagement in reverse - Lift and hold switch lever in highest position.

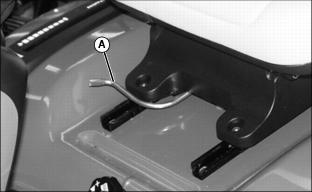

Pushing Machine (Using Free-Wheeling Lever)

IMPORTANT: Avoid damage! Transmission damage may occur if machine is moved incorrectly: |

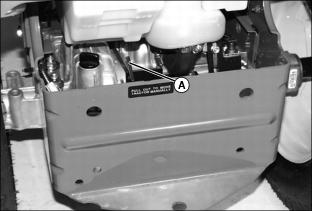

2. Pull out on free-wheeling lever (A).

3. Push machine to desired location.

NOTE: Free-wheeling lever will return to operating position when brake pedal is pressed.

Unplugging Mower or Optional Bagger

· Park machine safely and lock park brake before getting off of seat. |

3. Move throttle lever to slow position.

8. Wait for all moving parts to stop.

Transporting Machine on Trailer

Be sure trailer has all necessary lights and signs required by law.

1. Park trailer on a level surface.

2. Drive forward onto heavy-duty trailer with sides.

3. Lower mower to trailer deck.

5. Fasten machine to trailer with heavy-duty straps, chains, or cables. Both front and rear straps must be directed down and outward from machine.

Using Weights

Use weights to improve stability when operating on slopes or using attachments. |

NOTE: Install weights using instructions provided with weights. Remove weights when not required.

Using Front Weights

Install front wheel weights for better stability and steering control when using equipment such as rear-mounted grass bagger.

Using Rear Weights

Install rear weight bracket kit with suitcase weights or rear wheel weights when using front-mounted attachments such as a snowthrower or blade.

Installing Tire Chains

IMPORTANT: Avoid damage! Loose tire chains can cause machine damage. Periodically check chain tightness and adjust as necessary. |

NOTE: Chains are available from your John Deere dealer.

1. Park machine safely. (See Parking Safely in Safety section.)

2. Lay chains out flat with cross chain hook ends facing downward.

3. Remove any twists and tangles from cross chain and rim chain.

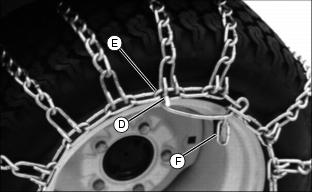

5. Drape chain over tire with lever fastener on outside of tire and cross link hooks (A) facing upward and away from tire.

6. Adjust chain for straightness and an even amount of cross chain links on each side of tire.

7. Place first cross chain (opposite end with fastener and inside hook) under tire.

8. Pull inside rim chain tight and hook inside hook.

9. Pull outside rim chain tight and hook outside lever fastener (B) by running end through a free link (C).

10. Close fastener by rotating it back 180° and engaging hook (D) on end of fastener into a rim chain link (E).

Make sure chain is centered on tire with approximately same number of free rim links (F) on inside and outside.

NOTE: Chain should be as tight as possible. If chain is loose, unhook fastener and pull chain tight again.

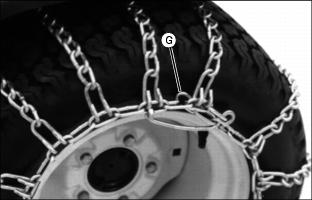

11. Tie excess rim chain links (G) back to rim chain.

12. Drive forward on chains 9-12 m (30-40 ft.) and recheck for tightness. Adjust as necessary.

Mowing Tips

Following recommendations will produce best lawn cut quality and appearance:

· Keep mower blades sharp. Dull blades will tear grass; tips of grass will then turn brown.

· Cutting grass too short may kill grass and let weeds grow easily. Suggested finished cut height range is 44-70 mm (1-3/4 to 2-3/4 in.).

· Adjust cutting height to remove only 1/3 of grass at a time.

· Mow grass often. Short grass clippings will decay quickly.

· Mow with engine at full throttle.

· Adjust travel speed to match mowing conditions:

· Travel at slow speed when mowing thick, tall grass, make sharp turns or trim around objects.

· Travel at moderate speed when mowing thin grass.

· Use a different mowing pattern for each mowing session. Overlap mowing paths 50-100 mm (2-4 in).

· Drive over ridges and through shallow ditches straight-on, not at an angle.

· A thick layer of mulched leave can prevent sunlight from getting to grass and smother it. Taller grass heights allow mulched leaves to dispense easier in lawn. Mulch leaves several times if needed.

· Use a thatcher in late spring or summer to pull up dead grass and aerate ground.