Service Miscellaneous

Checking Tire Pressure

c CAUTION: Avoid injury! Explosive separation of a tire and rim parts can cause serious injury or death:

c CAUTION: Avoid injury! Explosive separation of a tire and rim parts can cause serious injury or death:

ˇ Do not attempt to mount a tire without the proper equipment and experience to perform the job.

ˇ Always maintain the correct tire pressure. Do not inflate the tires above the recommended pressure. Never weld or heat a wheel and tire assembly. The heat can cause an increase in air pressure resulting in a tire explosion. Welding can structurally weaken or deform the wheel.

ˇ When inflating tires, use a clip-on chuck and extension hose long enough to allow you to stand to one side and NOT in front of or over the tire assembly.

ˇ Check tires for low pressure, cuts, bubbles, damaged rims or missing lug bolts and nuts.

|

M33418

1. Check tires for damage.

2. Check tire pressure with an accurate gauge.

3. Add air, if necessary:

Tire Size

|

Pressure

kPa (psi)

|

Front: 23x10.50-12

|

83 (12)

|

Rear: 26x12.00-12

|

83 (12)

|

Checking Tightness Of Wheel Bolts

M39810

Check wheel bolts often during the first 100 hours of operation. Tighten every other bolt in sequence until all bolts are at 81 to 95 Nˇm (60 to 70 lb-ft).

Fuel

c CAUTION: Avoid injury! Handle fuel with care, it is highly flammable:

c CAUTION: Avoid injury! Handle fuel with care, it is highly flammable:

ˇ DO NOT refuel machine while you smoke, when machine is near an open flame or sparks, or when engine is running. STOP engine.

ˇ Fill fuel tank outdoors.

ˇ Prevent fires: clean oil, grease and dirt from machine. Clean up spilled fuel immediately.

ˇ Do not store machine with fuel in tank in a building where fumes may reach an open flame or spark.

ˇ To prevent fire and explosion caused by static electric discharge, while you fill tank, use a non-metal fuel container. If you use a funnel, MAKE SURE it is PLASTIC. Avoid using a funnel which has a metal screen or filter.

ˇ Use only clean approved containers and funnels.

ˇ Store oil and fuel in an area protected from dust, moisture and other contamination.

|

IMPORTANT: Avoid damage! Avoid spilling fuel. Fuel can damage plastic and painted surfaces. DO NOT mix oil with gasoline. Unleaded gasoline with an octane rating of 87 or higher is recommended. Fuel tank capacity is 30 L (8 gal).

|

ˇ Use only clean, fresh, unleaded regular grade gasoline.

ˇ Remove any trash from top of fuel tank drain area.

ˇ Use summer blended fuel for warm weather operation and winter blended fuel for cold weather.

ˇ Never use fuel that is stale or has been stored for a long period of time:

Warm Weather - Maximum 60 days.

Cold Weather - Maximum of 90 days.

ˇ Fill fuel tank at the end of each day's operation. This helps to keep condensation out of fuel tank.

1. STOP engine. If engine is hot let it cool several minutes before you add fuel.

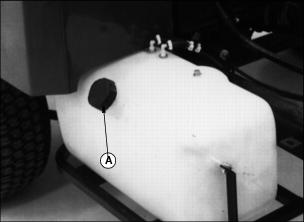

M71424

2. Remove fuel tank cap (A).

3. Fill tank only to bottom of filler neck.

4. Install fuel tank cap.

|