Introduction

Safety

Controls

Operating

Replacement Parts

Service Machine Safely

Service Intervals

Service Engine

Engine Warranty Maintenance Statement

Cleaning Air Intake Screen And Radiator

Checking And Cleaning Air Cleaner Elements

Tightening Or Replacing Fan Belt

Service Transmission

Service Steering & Brakes

Service Electrical

Service Miscellaneous

Troubleshooting

Storage

Assembly

Warranty

Specifications

John Deere Quality Statement

CopyrightŠ Deere & Company

Service Engine

Engine Warranty Maintenance Statement

Maintenance, repair, or replacement of the emission control devices and systems on this engine, which are being done at the customers expense, may be performed by any nonroad engine repair establishment or individual. Warranty repairs must be performed by an authorized John Deere dealer.

Avoid Fumes

ˇ If it is necessary to run an engine in an enclosed area, use an exhaust pipe extension to remove the fumes. |

Engine Oil

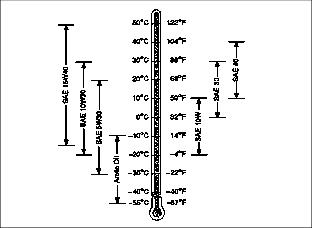

Use oil viscosity based on the expected air temperature range during the period between oil changes.

The following oil is preferred:

Other oils may be used if they meet one of the following:

ˇ API Service Classification SG

ˇ API Service Classification SF

1. Park vehicle on a level surface.

2. Check engine oil when oil is cold.

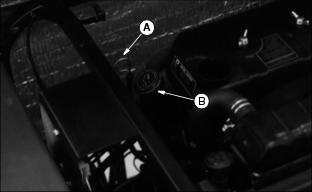

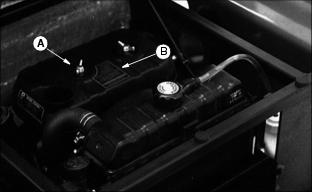

4. Remove dipstick (A). Wipe dipstick with a clean rag.

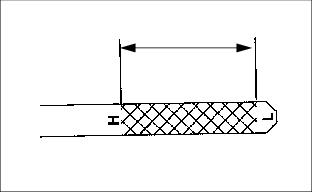

6. Remove dipstick. Check oil level on dipstick.

7. Oil level should be between FULL mark "H" and LOW mark "L" on dipstick.

8. To add oil, remove oil filler cap (B).

9. Add oil to bring oil level no higher than "H" mark on dipstick. (See Engine Oil in Service - Engines section for correct oil.)

11. Install and tighten oil filler cap.

IMPORTANT: Avoid damage! Change engine oil and filter after first 50 hours of break-in operation. When operating vehicle in extremely dusty or dirty conditions, change engine oil more often. |

Changing Engine Oil And Filter

1. Park vehicle on a level surface.

3. Run engine a few minutes to warm oil.

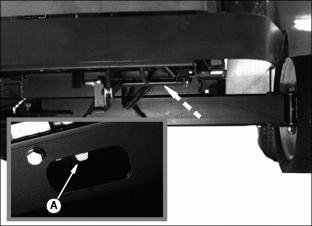

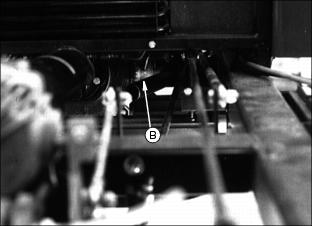

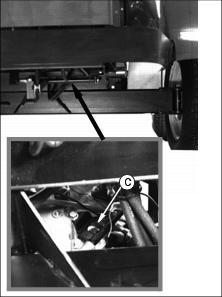

5. Place oil drain pan under drain plug (A) and oil filter (B). Remove drain plug and drain oil.

6. Remove filter using a filter wrench. Turn filter counterclockwise.

7. Apply a film of clean engine oil on seal of new filter.

8. Install filter. Turn filter until seal contacts mounting surface. Then turn filter BY HAND 1/2 turn more.

9. Install and tighten drain plug.

10. Remove filler cap (C). Add approximately 1.9 L (2 qt.) of oil. (See Engine Oil in this section for correct oil.)

11. Remove dipstick (D) to check oil level. Add oil only to FULL mark "H" on dipstick.

13. Start engine and run at slow speed for two minutes. Check for leaks around filter and drain plug. Stop engine. Check oil level.

14. Install dipstick. Lower seat.

Cleaning Air Intake Screen And Radiator

3. Clean screen with a brush or compressed air.

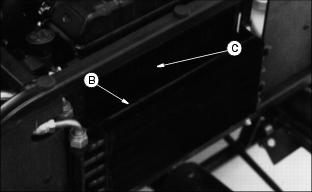

NOTE: Be sure all dirt and debris is removed between oil cooler (B) and radiator.

4. Clean radiator cooling fins (C) using compressed air (40 psi) or a brush.

Checking And Cleaning Air Cleaner Elements

IMPORTANT: Avoid damage! If you operate the vehicle in dusty |

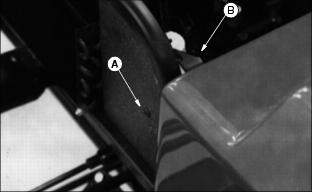

2. Remove two wing nuts (A) and cover (B).

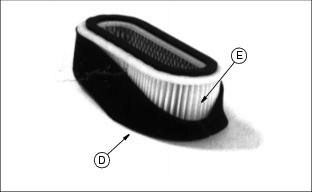

4. Check precleaner (D) for dirt and dust. If precleaner is dirty, remove it from paper element (E) and clean as follows:

ˇ Wash precleaner in warm, soapy water.

ˇ Rinse precleaner in clean water.

ˇ Squeeze precleaner to remove most of the water.

ˇ Apply 30 mL (1 oz) of clean engine oil to precleaner.

ˇ Squeeze precleaner to distribute oil evenly and to remove excess oil.

5. Check air cleaner paper element:

ˇ If paper element is dirty, tap gently on your hand to remove dust.

ˇ If the element is oily and very dirty or damaged, install a new element.

6. Install air cleaner and cover.

Service Cooling System Safely

Engine Coolant

IMPORTANT: Avoid damage! To prevent engine damage, DO NOT use pure antifreeze or more than 50% antifreeze in the cooling system. DO NOT mix or add any other type additives to the cooling system. |

Use ethylene glycol base coolant. These coolants usually have labels stating "For Automobile and Light Duty Service." These products are also often labeled for use in aluminum engines. Check container label before using.

Mix approximately 50 percent antifreeze with 50 percent distilled or deionized water. This mixture will provide freeze protection to -37° C (-34° F).

Certain geographical areas may require lower temperature protection. See the label on your antifreeze container or consult your John Deere distributor to obtain the latest information and recommendations.

The recommended antifreeze provides:

ˇ Corrosion-resistant environment within the cooling system.

ˇ Compatibility with cooling system hose and seal material.

ˇ Protection during cold and hot weather operations.

Checking Coolant Level

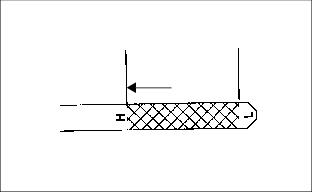

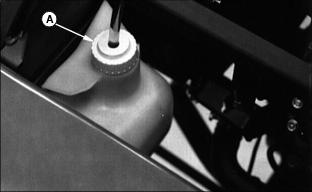

2. Coolant level MUST BE 25-51 mm (1-2 in.) in recovery

tank.

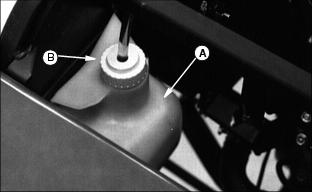

3. If coolant is low, remove coolant recovery tank cap (A).

4. Mix 50 percent ethylene glyco antifreeze with 50 percent distilled or deionized water.

5. Add mixture to coolant tank.

6. Install and tighten coolant recovery tank cap.

7. Clean debris from air intake screen and radiator. (See Cleaning Air Intake Screen And Radiator in this section.)

8. Check condition of hoses. Check for leaks or loose connections.

Draining Cooling System

1. STOP engine. Let engine cool.

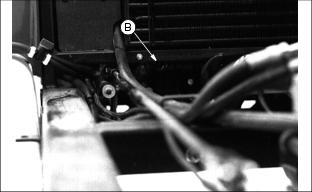

4. Slowly remove radiator cap (A).

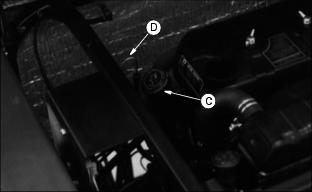

5. Open radiator petcock (B). Drain coolant into a bucket.

6. Remove block drain plug bolts (C) on each side of engine block to drain coolant.

7. After all coolant has drained, close radiator petcock and install block drain plug bolts.

8. Flush cooling system. (See Flushing Cooling System in this section.)

Flushing Cooling System

1. Fill cooling system with clean water and a cooling system cleaner recommended for aluminum engines. Follow the directions on the container.

2. Install and tighten radiator cap.

3. Start and run engine until it reaches operating temperature.

4. Drain cooling system immediately before rust and dirt settle. (See Draining Cooling System in this section.)

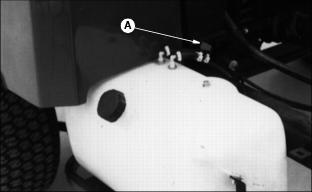

5. Remove two recovery tank screws (A) and recovery tank (B).

6. Remove tank cap and clean recovery tank.

8. Check condition of coolant system hoses and clamps.

9. Install new hoses, if necessary.

10. Fill cooling system. (See Filling Cooling System in this section.)

Filling Cooling System

1. Mix approximately 50 percent antifreeze with 50 percent distilled or deionized water. (See Engine Coolant in this section for type of antifreeze.)

2. Add mixture to radiator. Install and tighten radiator cap.

3. Run engine until it reaches operating temperature.

5. After engine cools, check coolant level in recovery tank (A). Level should be approximately 25-51 mm (1-2 in.).

6. Remove cap (B) to add coolant mixture if necessary.

7. Check condition of coolant system hoses and hose clamps.

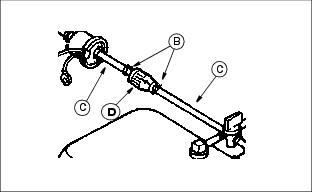

Replacing Fuel Filter

2. Close fuel shut-off valve (A).

3. Loosen hose clamps (B) to disconnect fuel hoses (C).

4. Remove fuel hoses from filter (D).

NOTE: Be sure arrow on fuel filter is pointed in the direction of fuel flow.

5. Connect hoses to new filter.

6. Slide clamps over hoses against filter.

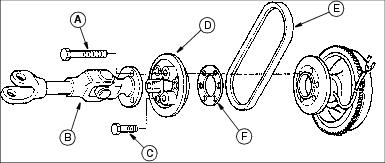

Tightening Or Replacing Fan Belt

2. Lift seat and remove both engine spark plugs.

NOTE: Rotate driveshaft for access to bolts, if necessary.

3. Remove three bolts (A) to disconnect drive shaft (B).

4. Remove three bolts (C) to remove outer sheave (D).

5. Remove belt (E) if it is to be replaced.

NOTE: To allow sheaves to fit closer together and increase belt tension, remove shim (F).

6. Remove spacer shim (F) if belt is to be tightened. Leave spacer in if installing a new belt.

7. Loosely install belt between sheave halves and start installing the three outer sheave-retaining bolts.

8. Rotate sheave assembly as bolts are tightened to allow belt to center in sheave halves and not be pinched in an OFF-CENTER position.

Adjusting Carburetor

NOTE: Carburetor is calibrated by the engine manufacturer and should not require any adjustments.

NOTE: If engine is operated at altitudes above 1829 m

(6,000 ft), some carburetors may require a special high altitude main jet. See your John Deere dealer.

NOTE: Possible engine surging will occur at high rpm when the transmission is in neutral ("N") and the PTO switch is in the OFF position. This is a normal condition due to the emission control system.

If engine is hard to start or runs rough, check the troubleshooting section of this manual.

After performing the checks in the troubleshooting section and your engine is still not performing correctly, contact your John Deere dealer.