Introduction

Product Identification

Safety

Operating

Replacement Parts

Service Intervals

Service Lubrication

Service Engine

Service Transmission

Service Electrical

Checking Battery Electrolyte Level

Replacing Instrument Panel Light Bulbs

Service Miscellaneous

Troubleshooting

Storage

Assembly

Specifications

Warranty

John Deere Quality Statement

Service Record

Service Electrical

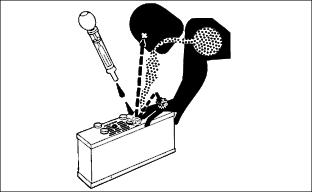

Checking Battery Electrolyte Level

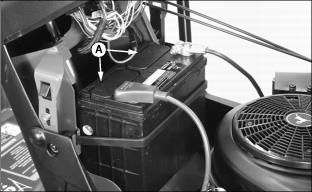

2. Remove battery manifold caps (A).

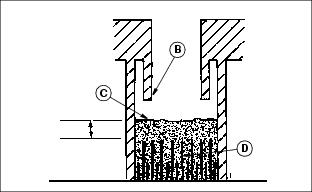

IMPORTANT: Avoid damage! DO NOT fill cells to bottom of filler neck (B). Electrolyte can overflow when battery is charged and cause damage. |

3. Electrolyte (C) should be 6 mm. (1/4 in) above plates (D).

4. If necessary, add distilled water.

Cleaning or Replacing Battery

Service Interval: Check and clean battery annually or every 100 hours of operation, which ever come first.

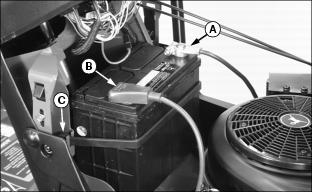

2. Remove negative (black) cable (A) from battery first.

3. Remove positive (red) cable (B).

4. Remove rubber hold-down strap (C) to remove battery.

5. Clean battery, battery terminals, cable ends, battery box, and other parts with a solution of 1 part baking soda to 4 parts water. KEEP solution out of battery cells.

6. Rinse all parts with clean water. Let dry.

8. Connect positive (red) cable to battery first, then negative (black) cable.

9. Apply general purpose grease on battery terminals to help prevent corrosion. Slip rubber cover over positive terminal. Install rubber holddown strap.

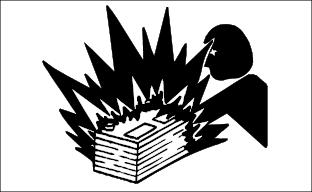

Charging the Battery

Follow the instructions on the battery charger or in the charger operator's manual, or use the instructions below as a guide.

BEFORE CHARGING A BATTERY:

· Wait until the battery has warmed to room temperature. Do not charge a frozen battery.

· Check the electrolyte level of each cell. (See Checking Battery Electrolyte Level in this section.)

· Install the battery cap(s) on the battery.

Turn OFF and unplug the charger before you connect cables to the battery or disconnect cables from the battery.

If the battery becomes warm to touch during charging:

· Stop charging the battery until it cools.

KEEPING BATTERY FULLY CHARGED:

1. Remove and clean battery. (See Cleaning Or Replacing Battery in this section.)

2. Check electrolyte level. (See Checking Battery Electrolyte Level in this section.)

3. Leave cell caps on battery while you charge it.

4. Connect positive (+) charger cable to positive (+) battery terminal.

5. Connect negative (-) charger cable to negative (-) battery terminal.

7. Charge battery. (See Charging Rates in this section.)

8. Unplug charger cord. Remove charger cables.

Charging Rates

See your battery charger or charger operator's manual for information on charging. Or read the information below to FULLY CHARGE your battery.

For a charger with a CURRENT ADJUSTMENT CONTROL:

· Adjust the control to 10 amps.

· Charge the battery for 6 to 12 hours.

For a charger with a switch for MAINTENANCE FREE, DEEP CYCLE, or NORMAL (CONVENTIONAL) setting:

· Use the MAINTENANCE FREE or DEEP CYCLE setting.

For a charger with SLOW CHARGE, FAST CHARGE, or BOOST CHARGE setting:

· DO NOT use the BOOST CHARGE setting.

· Use the SLOW CHARGE setting:

· For a charger rated at less than 10 amps.

· Use the FAST CHARGE setting:

· For a charger rated at 10 amps.

NOTE: NOTE: Your charger may have an AUTOMATIC STOP to prevent over-charging the battery:

· When the battery is fully charged

· When the battery is not in condition to take a charge.

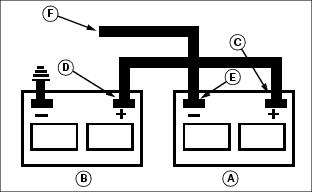

Using Booster Battery

1. Connect positive (+) booster cable to booster battery (A) positive (+) post (C).

2. Connect the other end of positive (+) booster cable to the disabled vehicle battery (B) positive (+) post (D).

3. Connect negative (-) booster cable to booster battery negative (-) post (E).

4. Connect the other end (F) of negative (-) booster cable to a metal part of the disabled machine frame away from battery.

5. Start the engine of the disabled machine and run machine for several minutes.

6. Carefully disconnect the booster cables in the exact reverse order: negative cable first and then the positive cable.

Replacing Headlight Bulb

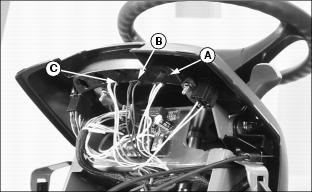

2. From inside the hood, turn bulb socket (A) 1/4 turn counterclockwise to remove.

3. Push in and turn bulb 1/4 turn counterclockwise out of socket.

4. Insert bulb socket into housing, push in and turn 1/4 turn clockwise to install.

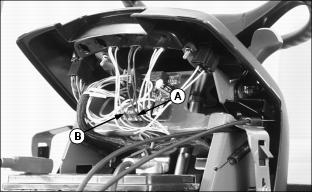

Replacing Instrument Panel Light Bulbs

2. Indicator light identification:

· A - Oil Pressure Indicator Light

· B - Battery Discharge Indicator Light

· C - Empty, Not used this application

3. Turn bulb socket 1/4 turn counterclockwise to remove.

4. Pull light bulb from socket.

5. Install bulb and socket and close hood.

Replacing Fuses

· 15 Amp Fuse (A) - Headlights