Introduction

Product Identification

Safety

Operating

Replacement Parts

Service Intervals

Service Lubrication

Service Engine

Engine Warranty Maintenance Statement

Changing Engine Oil and Filter

Servicing Air Cleaner Elements - GT225

Servicing Air Cleaner Elements - GT235

Service Transmission

Service Electrical

Service Miscellaneous

Troubleshooting

Storage

Assembly

Specifications

Warranty

John Deere Quality Statement

Service Record

Service Engine

Avoid Fumes

Engine Warranty Maintenance Statement

Maintenance, repair, or replacement of the emission control devices and systems on this engine, which are being done at the customers expense, may be performed by any nonroad engine repair establishment or individual. Warranty repairs must be performed by an authorized John Deere dealer.

Adjusting Carburetor

NOTE: The carburetor is calibrated by the engine manufacturer and should not require any adjustments.

If engine is operated at altitudes above 1829 m (6,000 ft.), some carburetors may require a special high altitude main jet. See your John Deere dealer.

Possible engine surging will occur at high rpm when the transmission is in neutral ("N") and the PTO switch is in the OFF position. This is a normal condition due to the emission control system.

If engine is hard to start or runs rough, check the TROUBLESHOOTING section of this manual.

After performing the checks in the troubleshooting section and your engine is still not performing correctly, contact your John Deere dealer.

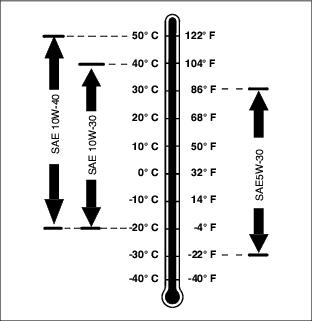

Engine Oil

Use oil viscosity based on the expected air temperature range during the period between oil changes.

The following John Deere oils are preferred:

Other oils may be used if above John Deere oils are not available, provided they meet the following specification:

· API Service Classification SG or higher

Checking Engine Oil Level

Service Interval: Check engine oil daily or every eight hours of operation.

1. Park tractor on a level surface and STOP engine. Let engine cool.

3. Clean area around dipstick to prevent debris from falling into crankcase.

4. Remove dipstick (A) and wipe off with a clean cloth.

5. Install dipstick into tube:

· On GT225; DO NOT TIGHTEN dipstick. Let dipstick threads rest on top of tube, rotate cap counterclockwise until it "clicks" or drops into the dipstick tube.

· On GT235: tighten cap to check oil level.

6. Remove dipstick. Check oil level on dipstick.

7. Oil must be between ADD and FULL marks on dipstick.

8. If oil level is low, add oil to bring oil level no higher than FULL mark on dipstick. (See Engine Oil in this section for type of oil.)

9. Install and tighten dipstick.

Changing Engine Oil and Filter

Service Interval: For initial break-in, change engine oil and filter at the first 25 hours and 50 hours of operation. After that change engine oil and filter annually or every 100 hours of operation.

1. Run engine a few minutes to warm the oil. Park tractor on a level surface.

2. Stop engine, ENGAGE park brake and remove key.

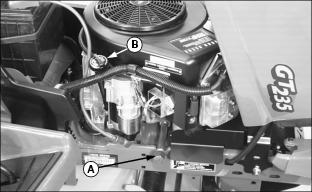

4. Position drain pan under drain valve (A).

5. Open drain valve (A) to drain oil.

7. Remove oil filter (C) using a filter wrench. Turn filter counterclockwise.

8. Apply a film of clean engine oil on seal of new filter. Install filter. Turn filter until seal contacts mounting surface. Then turn filter BY HAND 1/2 turn more.

10. Add engine oil (See Engine Oil in this section for type of oil.) DO NOT overfill.

Approximate engine oil capacities:

11. Install and tighten dipstick.

12. Start engine and run it at slow speed two minutes. Check for leaks around filter. Stop engine and wait two minutes.

13. Remove dipstick. Check oil level. If low, add oil only to FULL mark on dipstick. DO NOT overfill.

14. Install and tighten dipstick. Lower hood.

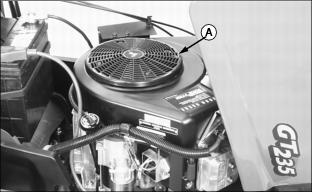

Cleaning Air Intake Screen

Service Interval: Check air intake screens daily or every eight hours of operation.

1. Stop engine and let it cool.

3. Clean air intake screen (A).

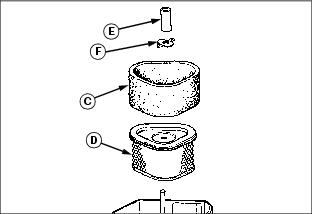

Servicing Air Cleaner Elements - GT225

Service Interval: Clean or Service air cleaner elements annually or every 50 hours of operation (Service more frequently under dusty conditions.)

2. Clean any dirt and debris from the air cleaner cover before removing cover.

3. Loosen knob (A) to remove air cleaner cover (B).

4. Inspect foam precleaner (C) without removing.

5. If foam precleaner is dirty, carefully remove from filter, leaving paper element in the air cleaner housing:

· Wash foam precleaner in a solution of warm water and liquid detergent.

· Rinse precleaner thoroughly. Squeeze out excess water in a dry cloth until precleaner is completely dry.

· Put approximately 30 ml. (1 oz.) of clean engine oil onto precleaner. Squeeze precleaner to distribute oil evenly. Squeeze out excess oil with a clean cloth.

6. Remove and replace paper filter element (D) ONLY if damaged or very dirty:

· Remove rubber tube sleeve (E) and wing nut (F).

· Carefully remove paper element (D) from air cleaner housing. REPLACE with a NEW element.

7. Carefully clean air cleaner housing. Prevent any dirt from falling into carburetor.

8. Install foam precleaner (C) and NEW paper element (D) onto post in air cleaner housing.

9. Install and tighten wing nut (F).

10. Install rubber tube sleeve (E) on post. Then push it down tight against wing nut.

11. Install air cleaner cover and tighten knob. DO NOT overtighten.

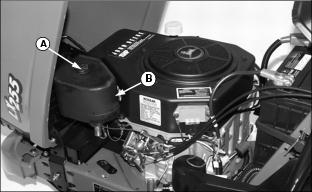

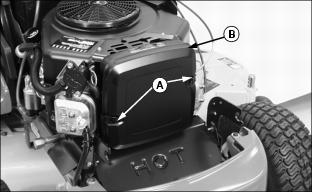

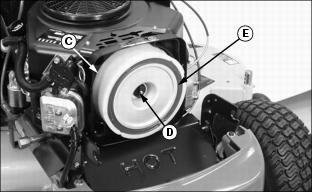

Servicing Air Cleaner Elements - GT235

Service Interval: Clean or Service air cleaner elements annually or every 50 hours of operation (Service more frequently under dusty conditions.)

1. Remove hood. (See Removing and Installing Hood in SERVICE MISCELLANEOUS section.)

2. Unhook both cover latches (A) to remove cover (B).

NOTE: If precleaner or paper element has a break or is damaged, replace it.

3. If precleaner (C) is dirty, remove it from paper element (E).

4. If paper element is excessively dirty, remove wing nut (D) and element (E). Replace it with a new element.

5. If precleaner is dirty, clean it as follows:

· Wash it in a solution of warm water and liquid detergent. DO NOT wash paper element.

· Squeeze excess water from precleaner.

· Allow precleaner to air dry.

· Put approximately 30 ml (1 oz.) of clean engine oil to precleaner.

· Squeeze precleaner to distribute oil evenly.

6. Install precleaner on paper element.

7. Install air cleaner cover and secure both cover latches.

8. Install hood. (See Removing and Installing Hood in SERVICE MISCELLANEOUS section.)

Replacing Fuel Filter

Service Interval: Change fuel filter every two years or every 200 hours of operation which ever comes first.

1. Park tractor on level surface. Stop engine and let it cool.

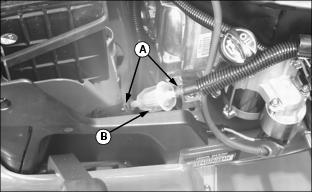

3. Using a pliers, slide two hose clamps (A) away from filter (B).

IMPORTANT: Avoid damage! When disconnecting fuel tank hose from filter, be sure to hold hose above fuel tank level so fuel does not run out. |

4. Disconnect hoses from filter.

IMPORTANT: Avoid damage! To properly install fuel filter, locate direction arrow on filter. Arrow indicates direction of fuel flow through filter. |

7. Connect hoses to new filter.

8. Install clamps and lower hood.

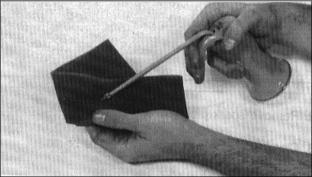

Checking Spark Plug

Service Interval: Inspect and regap spark plugs annually or every 100 hours of operation which ever comes first.

2. Disconnect spark plug wire(s) (A):

· On GT235; TWO spark plugs, one on each side.

4. Clean spark plug carefully with a wire brush.

· Pitted or damaged electrodes.

NOTE: In Canada, replace spark plug with resistor plug only.

6. Replace spark plug as necessary.

· On GT225; Gap must be 1 mm (0.040 in.).

· On GT235; Gap must be 0.76 mm (0.030 in.).

8. Install and tighten spark plug(s):

· On GT225; Tighten plugs to 40 N·m (30 lb-ft).