Introduction

Product Identification

Safety

Operating

Replacement Parts

Service Intervals

Service Lubrication

Service Engine

Service Transmission

Service Electrical

Service Miscellaneous

Cleaning and Repairing Plastic Surfaces

Cleaning and Repairing Metal Surfaces

Troubleshooting

Storage

Assembly

Specifications

Warranty

John Deere Quality Statement

Service Record

Service Miscellaneous

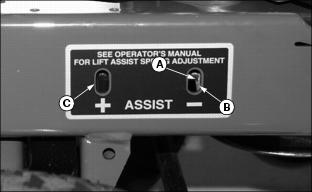

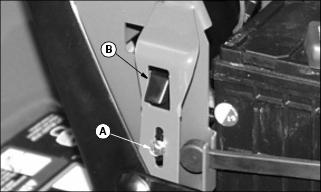

Adjusting Lift Assist Spring

The weight of the mower deck affects ease of lifting.

Adjust lift assist spring tension when installing a different deck to tractor.

· The yellow spring plug (A) should be visible in the (-) window (B).

· On THREE Spindle Mower Deck:

· The yellow spring plug (A) should be half way between the (+) window (C) and (-) window (B).

To adjust the tension on the lift assist spring:

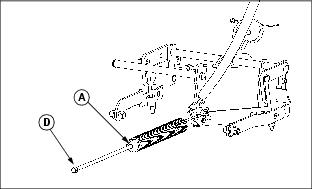

NOTE: Long adjusting bolt (D) is located behind front bumper under frame.

· Turn long adjusting bolt (D) clockwise to tighten spring tension and move the yellow spring plug toward the front of the tractor or into the (+) window.

· Turn long adjusting bolt (D) counterclockwise to loosen spring tension and move yellow spring plug toward the rear of the tractor or into the (-) window.

1. STOP engine. If engine is hot let it cool several minutes before you add fuel.

2. Remove grass clippings and other trash from tank area.

4. Fill tank with fresh fuel only to bottom of filler neck.

Approximate fuel tank capacity:

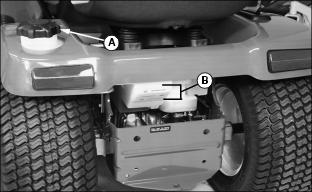

6. Check fuel level according to marks (B) on tank.

Removing and Installing Hood

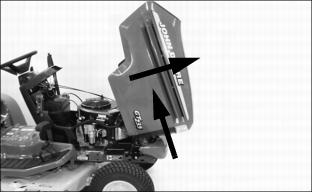

Remove Hood

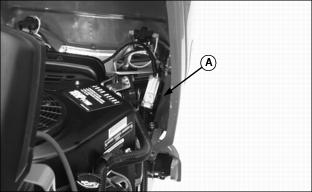

2. Disconnect wiring harness (A).

3. Lift and pull hood away from tractor.

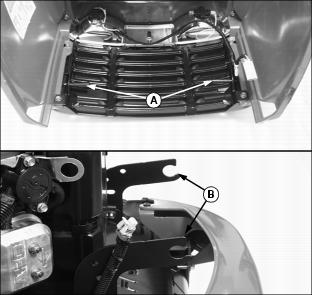

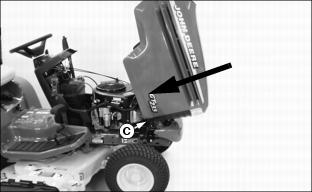

Install Hood

1. Align hood pivot studs (A) with pivot brackets (B) and install hood.

2. Connect wiring harness (C).

Adjusting Hood Latch

1. Open hood and loosen cap screw (A).

4. Adjust hood latch on other side of tractor.

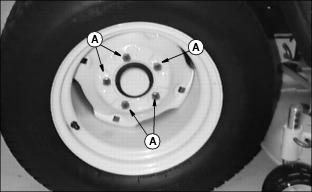

Check Wheel Bolts

NOTE: Serious accident may occur causing serious injury if wheel bolts (A) are not tight.

1. Check wheel bolt tightness often during the first 100 hours of operation.

Wheel bolt torque is 88 N·m (65 lb-ft.).

Cleaning and Repairing Plastic Surfaces

Your John Deere dealer has the professional materials needed to properly remove surface scratches from any plastic surfaces, do not attempt to paint over marks or scratches in plastic parts.

1. Rinse hood and entire machine with clean water to remove dirt and dust that may scratch the surface.

2. Wash surface with clean water and a mild liquid automotive washing soap.

3. Dry thoroughly to avoid water spots.

4. Wax the surface with a liquid automotive wax. Use products that specifically say "contains no abrasives."

5. Buff applied wax by hand using a clean, soft cloth.

Cleaning and Repairing Metal Surfaces

Cleaning:

Follow automotive practices to care for your vehicle painted metal surfaces. Use a high-quality automotive wax regularly to maintain the factory look of your vehicle's painted surfaces.

Repairing Minor Scratches (surface scratch):

1. Clean area to be repaired thoroughly.

2. Use automotive polishing compound to remove surface scratches.

3. Apply wax to entire surface.

Repairing Deep Scratches (bare metal or primer showing):

1. Clean area to be repaired with rubbing alcohol or mineral spirits.

2. Use paint stick with factory-matched colors available from your John Deere dealer to fill scratches. Follow directions included on paint stick for use and for drying.

3. Smooth out surface using an automotive polishing compound. Do not use power buffer.