Introduction

Product Identification

Safety

Operating

Replacement Parts

Service Intervals

Service Lubrication

Service Engine

Service Transmission

Service Steering & Brakes

Service Mower

Service Electrical

Service Miscellaneous

Removing and Installing Rear Drive Wheels

Tightening Drive Wheel Hardware

Removing and Installing Front Caster Wheels

Cleaning and Repairing Plastic Surfaces

Cleaning and Repairing Metal Surfaces

Troubleshooting

Storage

Assembly

Specifications

Warranty

John Deere Quality Statement

Service Record

Service Miscellaneous

Filling Fuel Tank

Use regular grade 87 octane unleaded fuel.

Add John Deere fuel stabilizer to fuel before using it in your machine to prevent engine damage due to stale fuel. Follow directions on stabilizer container.

NOTE: Capacity of fuel tank is 34 L (9 gal).

1. Stop engine, let it cool several minutes before adding fuel.

2. Remove any grass or debris from top of fuel tank.

4. Fill tank with fuel only to 25 mm (1 in.) below bottom of filler neck.

Checking Tire Pressure

2. Check tire pressure with an accurate gauge.

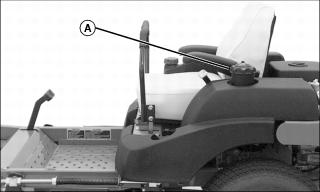

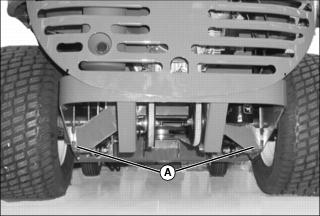

Removing and Installing Rear Drive Wheels

Removing:

1. Park machine safely. (Refer to Parking Safely in the Safety section.)

2. Slightly loosen four wheel nuts.

3. Lift machine with a safe lifting device centered under tire support frame (A) on the side the tire is being removed from.

Installing:

2. Install wheel nuts. Tighten wheel nuts alternately until recommended torque value is reached.

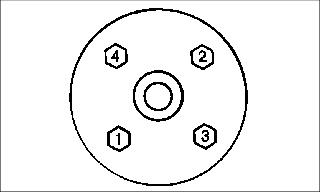

Tightening Drive Wheel Hardware

1. Tighten rear wheel nuts to 100 N·m (75 lb-ft.)

2. Tighten wheel nuts in numbered sequence shown. Tighten alternately until recommended torque value is reached.

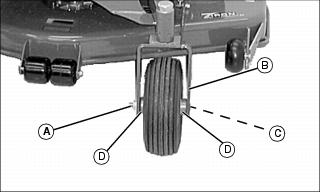

Removing and Installing Front Caster Wheels

Removing

1. Park machine safely. (Refer to Parking Safely in the Safety section.)

2. Lift front of machine with a safe lifting device.

3. Remove hex nut (A) and wheel bolt (C).

4. Remove wheel and cups from assembly yoke (B).

Installing

1. Install replacement wheel with cups (D).

2. Install wheel bolt (C) and hex nut (A).

Cleaning and Repairing Plastic Surfaces

Your John Deere dealer has the professional materials needed to properly remove surface scratches from any plastic surfaces, do not attempt to paint over marks or scratches in plastic parts.

1. Wash surface with clean water and a mild liquid automotive washing soap.

2. Dry thoroughly to avoid water spots.

Cleaning and Repairing Metal Surfaces

Cleaning:

Follow automotive practices to care for your vehicle painted metal surfaces. Use a high-quality automotive wax regularly to maintain the factory look of your vehicle's painted surfaces.

Repairing Minor Scratches (surface scratch):

1. Clean area to be repaired thoroughly.

2. Use automotive polishing compound to remove surface scratches.

3. Apply wax to entire surface.

Repairing Deep Scratches (bare metal or primer showing):

1. Clean area to be repaired with rubbing alcohol or mineral spirits.

2. Use paint stick with factory-matched colors available from your John Deere dealer to fill scratches. Follow directions included on paint stick for use and for drying.

3. Smooth out surface using an automotive polishing compound. Do not use power buffer.