38-Inch for F510 and F525 Front Mowers

Introduction

Safety Signs

Preparing Vehicle

Installing

Removing

Operating

Service Machine Safely

Service

Lubricating Worm Gear and Discharge Chute

Reversing or Replacing Scraper Blade

Troubleshooting

Storing Machine

Assembly

Specifications

John Deere Service Literature

John Deere Quality Statement

CopyrightŠ Deere & Company

Service

Service Intervals

Service Record

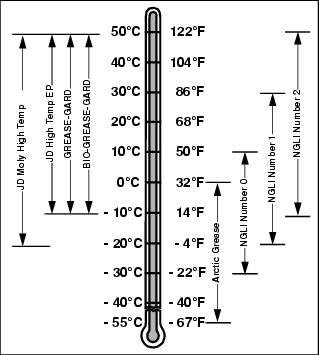

Grease

Use grease based on the expected air temperature range during the service interval.

The following greases are preferred:

ˇ John Deere Moly High Temperature EP Grease.

ˇ John Deere High Temperature EP Grease.

Other greases may be used are:

ˇ SAE Multipurpose EP Grease with 3 to 5 percent molybdenum disulfide.

ˇ Greases meeting Military Specification MIL-G-10924C may be used as arctic grease.

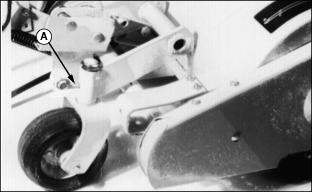

Lubricating Caster Wheels

Grease caster wheels (A) with John Deere Moly High Temperature EP Grease or an equivalent.

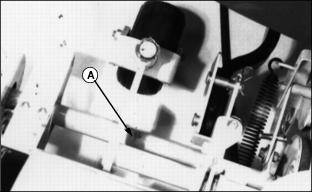

Lubricating Countershaft

Grease countershaft (A) with John Deere Moly High Temperature EP Grease or an equivalent.

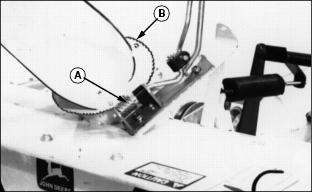

Lubricating Worm Gear and Discharge Chute

1. Grease worm gear (A) and discharge chute (B) with John Deere Moly High Temperature EP Grease or equivalent.

2. Grease oil tension block with John Deere Moly High Temperature EP Grease or equivalent.

Lubricating Drive Chain

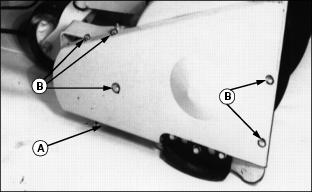

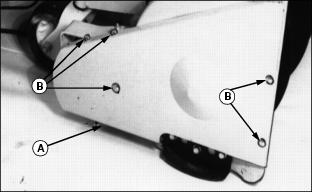

1. Remove bolts (B) to remove chain shield (A).

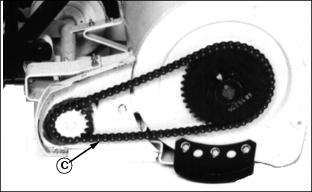

2. Spray chain (C) with John Deere TY6240 chain lube spray or equivalent.

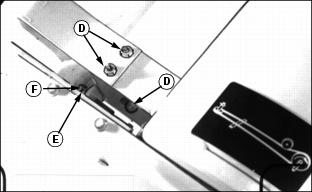

Adjusting Chain

1. Remove bolts (B) to remove shield (A).

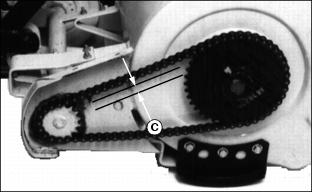

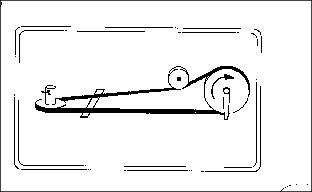

2. Chain deflection (C) 3-6 mm (1/8-1/4-in.)

3. To adjust chain deflection:

ˇ Turn bolt (F) until deflection is correct.

ˇ Tighten bolts (D) and nut (E).

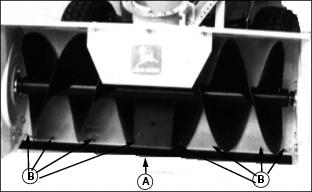

Reversing or Replacing Scraper Blade

Reverse blade (A) when edge is rough or worn. Replace blade if it is bent.

3. Fasten blade with eight bolts.

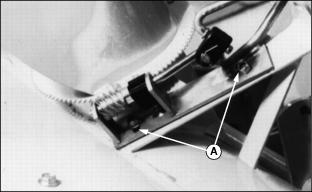

Adjusting Worm Gear

1. Loosen nuts (A) on two mounting bolts.

2. Position worm gear so grooves on gear mesh with teeth on discharge spout.

NOTE: Spout should rotate FREELY when turning crank handle.

NOTE: If snowthrower spout starts rotating on its own while blowing snow, turn nut under black tension block up to adjust tension.

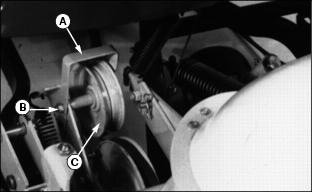

Replacing Drive Belt

1. Remove snowthrower from tractor. (See Removing Snowthrower in Removing section.)

2. Loosen nut (B) to loosen belt guide (A).

3. Remove belt from lift idler (C).

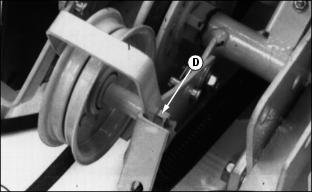

ˇ Loosen idler mounting bolt and lock nut (D).

NOTE: Refer to belt installation decal at right or decal located on snowthrower shell for proper belt routing.

ˇ Put new belt between idler and belt guide below idler.

ˇ Tighten idler mounting bolt after routing belt.

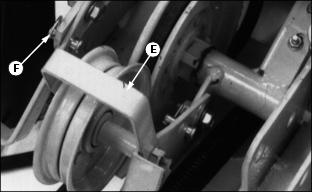

ˇ Pull belt idler arm (E) forward and remove drilled pin and spring locking pin (F).