Introduction

Safety Signs

Controls

Operating

Lawn Care

Replacement Parts

Service Machine Safely

Service Intervals

Service Engine

Changing Engine Oil And Filter

Check Air Restriction Indicator

Replace/Adjust Alternator Belt

Service Transmission

Service Steering & Brakes

Service Electrical

Service Miscellaneous

Troubleshooting

Storing Vehicle

Assembly

Specifications

Warranty

John Deere Quality Statement

Copyright© Deere & Company

Service Engine

Avoid Fumes

· If it is necessary to run an engine in an enclosed area, use an exhaust pipe extension to remove the fumes. |

Engine Oil

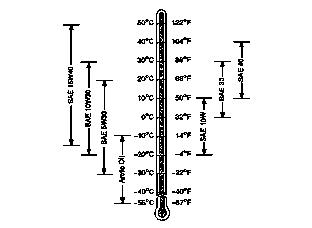

Use oil viscosity based on the expected air temperature range during the period between oil changes.

The following oil is preferred:

The following oil is also recommended:

· John Deere TORQ-GARD SUPREME®

Other oils may be used if they meet one of the following:

· API Service Classification CE

· API Service Classification CD

Viscosity grade SAE 15W-40 is preferred.

If John Deere PLUS-50 engine oil and a John Deere oil filter are used, the oil and filter service interval may be extended by 50 hours.

If diesel fuel exceeding 0.5% sulfur content is used, reduce the service interval for engine oil and filter by 50%.

Checking Engine Oil Level

1. Park Front Mower on a level surface.

2. STOP engine. Let oil drain down a short time.

4. Keep oil between ADD and FULL.

Changing Engine Oil And Filter

1. Park Front Mower on a level surface.

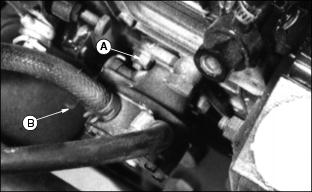

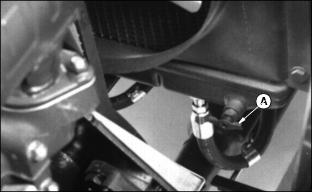

3. Remove drain plug (A). Change filter while oil drains.

5. Apply clean oil to new filter gasket.

6. Install filter until it contacts mounting surface. Then turn filter BY HAND 3/4 turn more.

9. Run engine. STOP engine. Check oil level.

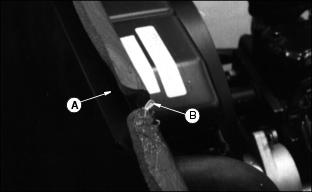

Check Air Intake Screen

If screen (A) is dirty, clean it:

· Lift seat as high as it will go.

· If screen is very dirty, remove two wing nuts (B) and screen.

· Check and/or clean radiator fins.

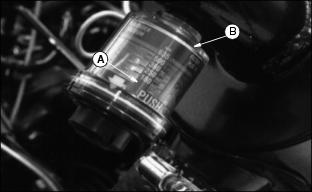

Check Air Restriction Indicator

Check air restriction indicator:

· Push reset button on bottom of indicator.

· Start engine. Run at full throttle.

· Change primary element only when yellow plunger (A) is up to the red line (B).

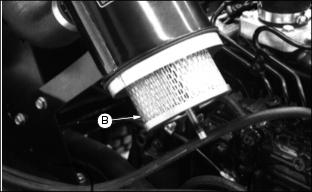

Change Air Cleaner Elements

When plunger in air restriction indicator is up to the red line, change the primary element.

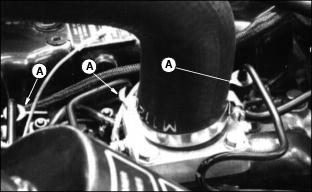

1. STOP engine. Remove air cleaner cover (A).

2. Remove and discard element (B).

3. Install new element and cover.

4. Tighten wing nuts until you can no longer turn the element. Then tighten nut 1/8 to 1/4 turn more. DO NOT use other hardware in place of wing nuts.

5. Start engine. Check air restriction indicator. If indicator shows 20-in.(500 mm) vacuum or more, change secondary element. (See Changing Secondary Element in this section.)

Changing Secondary Element

1. Remove cover and primary element.

2. Remove and discard element (A).

4. Tighten wing nut. Do not use other hardware in place of wing nuts.

5. Install primary element and cover. Tighten wing nuts.

Bleeding Fuel System

Do not service injectors or injection pump. Special training and tools are needed. Read your warranty.

Bleed the fuel system after you work on it or run out of fuel.

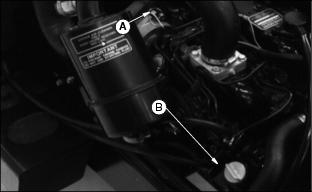

1. STOP engine. Loosen screw (A).

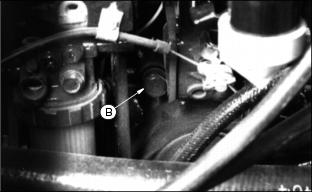

2. Pump lever (B) until fuel flows from around screw.

3. Tighten screw. Start engine.

4. If engine will not start or runs rough for more than 30 seconds:

· Loosen three nuts (A) shown. Start with nut closest to injection

pump.

5. Run engine until fuel without bubbles flows from around each nut, then tighten nut.

Service Cooling System Safely

3. If radiator cap is OK, coolant level should be 25-50 mm

(1-2 in.) in the overflow tank.

4. If cap is faulty, tank may show correct level, but radiator coolant may be low.

5. Remove cap to check coolant:

6. Remove cap when engine is cool.

7. If needed, add mixture of equal amounts of ethylene glycol antifreeze and water. Do not use any additives.

Draining Cooling System

IMPORTANT: Avoid damage! Check condition of radiator cap when you change coolant. Check condition of coolant hoses. You may need to replace hoses after 2 years of operation. |

2. Remove radiator cap slowly.

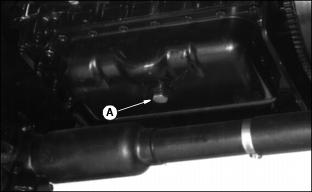

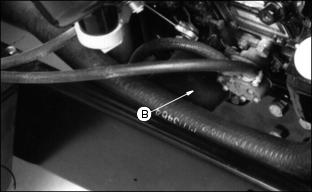

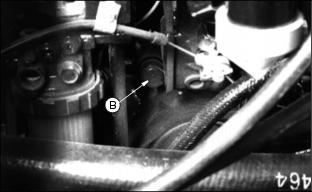

5. After coolant drains, close petcock (A) and drain fitting (B).

Flushing Cooling System

IMPORTANT: Avoid damage! To prevent engine damage, DO NOT pour water into a hot engine. DO NOT operate engine without coolant. |

1. Fill cooling system with clean water and cleaner suitable for aluminum radiator and cast iron block. Follow the directions on the can.

3. Run engine to the operating temperature.

4. Remove radiator cap SLOWLY.

5. Loosen petcock (A) and drain fitting (B). Drain cooling system before rust and dirt settle.

6. Close petcock (A) and drain fitting (B).

7. Remove and clean the overflow tank.

Filling Cooling System

IMPORTANT: Avoid damage! For cold weather use ethylene glycol antifreeze. Use equal amounts of clean, soft water and antifreeze. |

1. Fill cooling system. Capacity is 7.6 L (8 qt). For temperatures above freezing, use clean, soft water.

3. Run engine to the operating temperature.

4. STOP the engine. After engine cools, coolant should be

25-50 mm (1-2 in.)high in the overflow tank with the radiator full.

Replace/Adjust Fan Belt

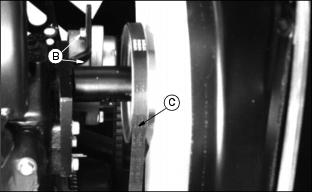

1. Remove three bolts (A) holding drive shaft.

2. Loosen two bolts at front of drive shaft where it clamps to hydrostatic input shaft.

5. Remove belt. Install new belt and drive shaft.

6. Adjust tension. Belt should deflect 6 mm (1/4 in.) with light-to-moderate pressure at (C)

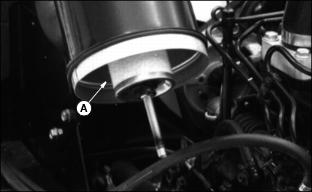

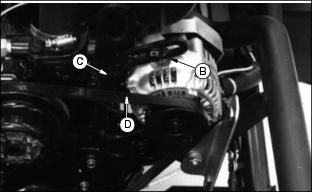

Replace/Adjust Alternator Belt

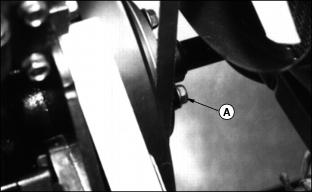

1. Remove four bolts and cover (A).

3. Remove belt or tighten belt. Belt should deflect 6 mm (1/4 in.) at (D) with moderate thumb pressure.

5. Adjust belt and tighten bolts (B) and (C).

Fuel Filter And Sediment Bowl

To clean the sediment bowl and change the filter:

1. Turn fuel tank pointer to OFF.

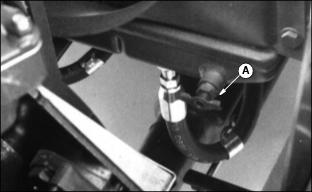

2. Turn collar (A) counterclockwise to remove bowl and filter.

3. Clean bowl. Replace filter.

4. Bleed fuel system. (See

Bleeding Fuel System in this

section.)