Introduction

Safety Signs

Controls

Operating

Lawn Care

Replacement Parts

Service Machine Safely

Service Intervals

Service Engine

Service Transmission

Transmission and Hydraulic Oil

Alternative And Synthetic Lubricants

Transmission Neutral Adjustment

Check Transmission/Hydraulic Oil Level

Change Transmission Oil And Filter

Service Steering & Brakes

Service Electrical

Service Miscellaneous

Troubleshooting

Storing Vehicle

Assembly

Specifications

Warranty

John Deere Quality Statement

CopyrightŠ Deere & Company

Service Transmission

Anti-Chatter Transmission Oil

NOTE: NOTE: Tractor is filled with John Deere Low Viscosity HY-GARDŽ (J20D) transmission oil at the factory. DO NOT mix oils.

These tractors are equipped with a hydraulic wet disc clutch transmission. To avoid chatter, use only Low Viscosity HY-GARDŽ (J20D) transmission oil. DO NOT use type "F" automatic transmission fluid.

John Deere Low Viscosity HY-GARDŽ (J20D) transmission oil is specially formulated to minimize clutch chatter, and to provide maximum protection against mechanical wear, corrosion, and foaming.

IMPORTANT: Avoid damage! When operating in temperatures below -7°C (20°F), you must use Low Viscosity HY-GARDŽ or transmission damage will occur. |

Transmission and Hydraulic Oil

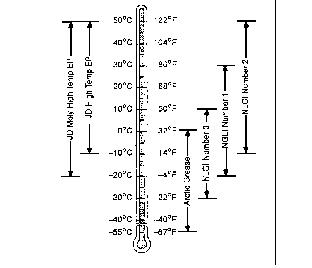

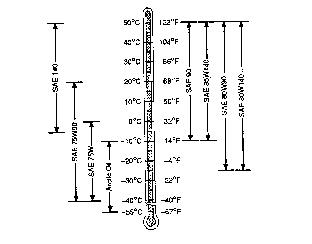

Use oil viscosity based on the expected air temperature range during the period between oil changes.

John Deere HY-GARDŽ is recommended.

Other oils may be used if they meet the following:

Grease

Use grease based on the expected air temperature range during the service interval.

The following greases are preferred:

ˇ John Deere MOLY HIGH TEMPERATURE EP GREASE

ˇ John Deere HIGH TEMPERATURE EP GREASE

Other greases may be used if they meet one of the following:

ˇ SAE Multipurpose EP Grease with a maximum of 5% molybdenum disulfide

Greases meeting Military Specification MIL-G-10924F may be used as arctic grease.

Alternative And Synthetic Lubricants

Conditions in certain geographical areas may require lubricant recommendations different from those printed in this operator's manual. Some John Deere lubricants may not be available in your location. Consult your John Deere dealer to obtain information and recommendations.

Synthetic lubricants may be used if they meet the performance requirements as shown in this operator's manual.

Transmission Neutral Adjustment

This adjustment should be done ONLY if the machine "creeps" when pedals are in NEUTRAL.

NOTE: If creep is intermittent, inspect transmission control linkage for wear or damage or return to neutral linkage for binding before adjusting transmission neutral..

1. Lift machine with a hoist and support both front and rear wheels off the ground.

2. Put jackstands under frame and rear axle.

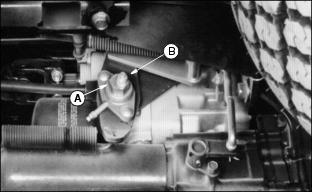

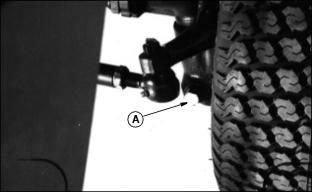

3. Locate eccentric nut for adjustment on behind right front tire under machine.

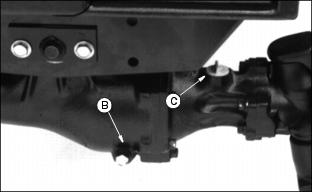

4. Loosen lock nut (B). Loosen nut only enough to allow eccentric nut to turn.

5. Have someone push down center of seat cushion to activate seat safety switch, or use a jumper wire to bypass the seat switch. DO NOT SIT ON SEAT.

6. Start engine and run at low idle. Put transaxle in HI range.

7. With brakes DISENGAGED, turn eccentric nut (A) forward and backward until drive wheels stop turning.

NOTE: Eccentric nut MUST BE positioned rearward and eccentric positioned forward for correct adjustment.

8. Hold adjustment and tighten lock nut. Make sure adjustment did not change.

9. Put transaxle shift lever in NEUTRAL. Depress both forward and reverse speed pedals, then release.

10. Again put transaxle in HI range. Check neutral adjustment. Repeat adjustment until drive wheels stop turning.

11. If drive wheels continue to turn when in NEUTRAL, lower machine to the ground. Remove seat switch jumper wire, if used.

12. Check for worn or binding return-to-neutral linkage or too light of tension on neutral return spring. If machine STILL "creeps" when in NEUTRAL, see your John Deere dealer.

Check Transmission/Hydraulic Oil Level

Use ONLY John Deere Low Viscosity HY-GARDŽ (J20D) Transmission/Hydraulic Oil.

Check oil when transmission is cold.

1. Park Front Mower on a level surface.

2. STOP the engine. Lower attachment to the ground.

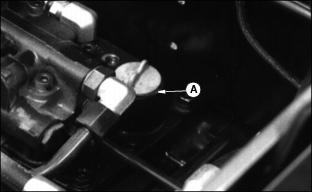

3. Lift seat. Remove and clean dipstick (A).

4. Install dipstick but do not turn it. Oil should be in (XXX) area on dipstick, but not above top mark. Do not run engine if oil is below bottom mark.

Change Transmission Oil And Filter

Use ONLY John Deere Low-Viscosity HY-GARDŽ (J20D) Transmission/Hydraulic Oil.

1. Park Front Mower on a level surface.

2. Run engine to warm oil. STOP engine.

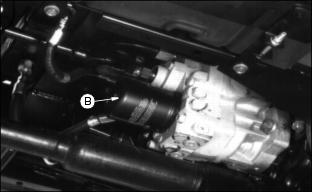

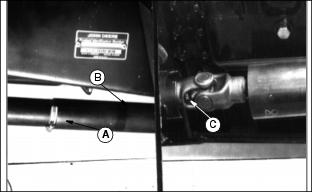

3. Remove drain plug (A) and plug on right side of transmission.

4. Change filter (B) while oil is draining.

5. Fill filter half full of oil.

6. Install filter quickly. Turn it until seal contacts base, then turn it BY HAND 1/2 turn more.

7. Remove three bolts (C), housing and screen.

11. Start engine. Check for leaks around drain plugs and filter.

12. Move lift lever back and forth several times.

13. STOP engine. Check oil level.

MRWD Oil

John Deere GL-5 Gear Lubricant is recommended.

Other oils meeting one or more of the following may be used:

ˇ Military Spec MIL-L-2105B or C or D

Use MIL-L-10324A oil below -10°C (+14°F).

Check MRWD Oil Level

1. Park Front Mower on a level surface.

2. Remove and clean dipstick (A).

3. Install dipstick but do not turn it.

4. Remove dipstick. Check oil level.

5. Oil should be in (XXX) area on dipstick but not above top mark. If oil is low, do not operate Front Mower.

Change MRWD Oil

1. Change oil right after operating Front Mower, while oil is warm.

2. Remove drain plug (A) from each side.

3. Remove plug (B), and dipstick (C).

4. After oil is drained, install plugs.

5. Install 2.1 L (2-1/4 qt) oil. Allow time for oil to drain into outer housings.

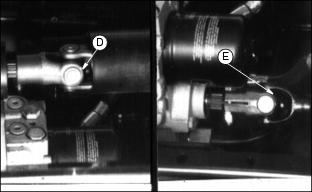

Lubricate U-Joints

C - MRWD Shaft (Front U-Joint)

2. Slide tube (B) to lubricate points (C) and (D).

4. Lubricate all points with arctic grease when below -30°C (-22°F).