Introduction

Product Identification

Safety

Understanding The Machine Safety Labels

Protect Children and Prevent Accidents

Handling Waste Product and Chemicals

Operating

Replacement Parts

Service Intervals

Service Lubrication

Service Engine

Service Chain Case

Service Hydraulics

Service Steering & Brakes

Service Electrical

Service Miscellaneous

Troubleshooting

Storage

Specifications

Warranty

John Deere Quality Statement

Service Record

Safety

Understanding The Machine Safety Labels

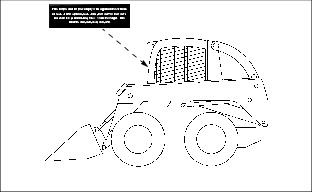

The machine safety labels shown in this section are placed in important areas on your machine to draw attention to potential safety hazards.

On your machine safety labels, the words DANGER, WARNING, and CAUTION are used with this safety-alert symbol,. DANGER identifies the most serious hazards.

The operator's manual also explains any potential safety hazards whenever necessary in special safety messages that are identified with the word, CAUTION, and the safety-alert symbol,.

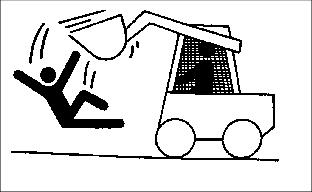

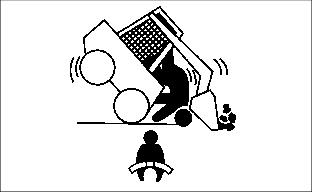

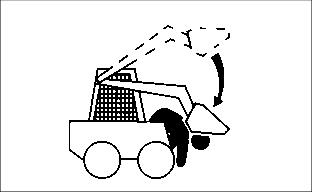

CAUTION - Avoid Overturn

· Avoid Steep Slopes and Speed Turns

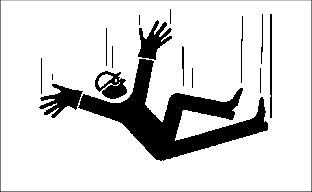

DANGER - Avoid Death

Before Removing Seat Belt and Leaving Seat:

· Lower Boom To Ground or Rest Boom on Stops

· Engage Park Brake, Stop Engine and Remove Key

CAUTION - Avoid Injury

· Know Location and Function of Controls

· Keep Screens and Windows in Place

· Keep Children and Others Away

· Lower Boom, Engage Park Brake, Stop Engine and Remove Key Before Leaving

· Keep Cab Clean, Especially Pedal Area

CAUTION - Avoid Injury

|

If you must leave boom raised when exiting, be sure boom locks are in the LOCKED position and the boom is resting on the locks. |

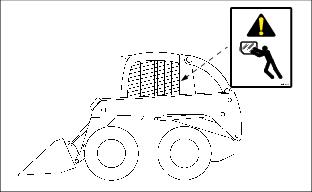

WARNING - Emergency Cab Exit

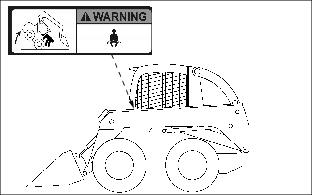

WARNING - Avoid Injury

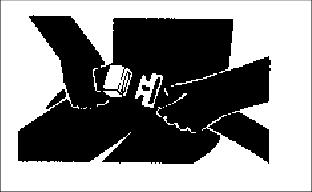

|

Always wear seat belt when operating skid steer. Failure to wear seat belt could result in an injury from an accident such as an overturn. |

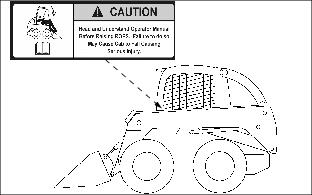

CAUTION - Avoid Injury

|

Read and Understand Operator Manual Before Raising ROPS. Failure to do so May Cause Cab to Fall Causing Serious Injury. |

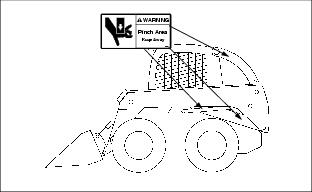

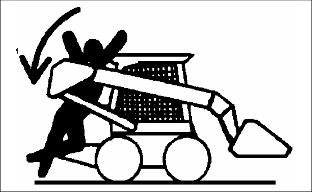

WARNING - Pinch Area

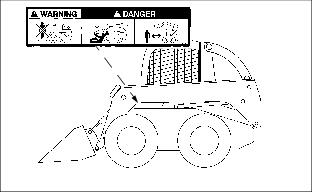

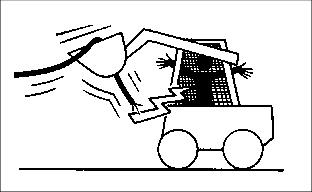

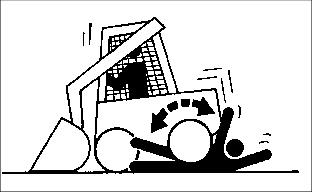

WARNING - DANGER

· DO NOT allow riders in the bucket.

· Never stand or lean anywhere on skid steer or linkage will crush you.

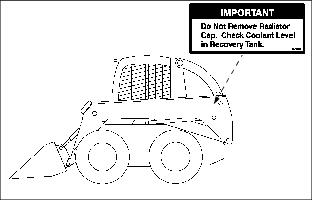

IMPORTANT

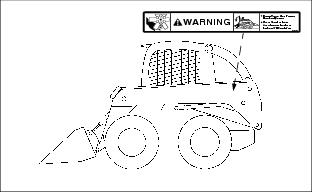

WARNING

· Boom Moves Near Engine Hood and Frame.

· Never Stand Or Lean Anywhere On Skid Steer Or Linkage Will Crush You.

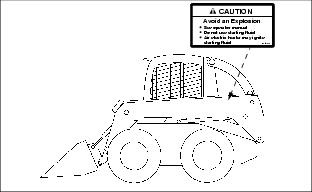

CAUTION - Avoid an Explosion

· Air electric heater may ignite starting fluid

ROPS Certification Label

Operator Training Required

· Study operation section of this manual before operating the machine. Know location and function of all controls.

· Operate machine in an open, unobstructed area under the direction of an experienced operator.

· Operator experience is required to learn the moving, stopping, turning, and other operating characteristics of the machine.

Use Seat Belt Properly

· Use a seat belt when you operate with a roll-over protective structure (ROPS) or cab to minimize chance of injury from an accident such as an overturn.

· Do not operate skid steer from anywhere but the operator's seat with seat belt fastened.

Use Handholds and Steps

· Maintain a three-point contact with steps and handholds. Face machine when getting in or out of machine. Do not use controls as handholds.

· Do not jump in or out of machine. Do not exit a moving machine.

· Be careful of slippery platforms, steps, and handholds. Keep platforms, steps, and handholds clean and free of debris.

Operate Safely

· Do not work under overhangs, electric wires, or where there is danger of a slide.

· Never use starting fluid to start engine. This machine has an electric air heater which can ignite starting fluid.

· Keep people and pets out of the worksite. Stop machine if anyone enters the worksite.

· If you hit an object, stop the machine and inspect machine for damage. Make repairs before you operate again. Keep machine and attachments properly maintained and in good working order. Keep all shields and guards in place. Keep screens and windows in place.

· Do not leave machine unattended while it is running.

· Operate only during daylight or with adequate artificial light.

· Be careful of traffic when operating near or crossing roadways.

· Do not reach out of operator's station. Boom is lowered and raised during operation and can cause injury.

· Do not use a bucket or attachment as a work platform or for carrying people.

· Do not move loads over the heads of other people.

· Keep operator's station clean and clear of debris, especially area around pedals.

Protect Children and Prevent Accidents

Protect Children:

· Never assume that children will remain where you last saw them. Children are attracted to machine activity; stay alert to the presence of children.

· Turn machine off if a child enters the worksite.

· Use extra care when you come to blind corners, shrubs, trees, or other objects that may block your vision.

· Do not let children or an untrained person operate the machine.

· Do not carry or let children ride on machine or any attachment.

Help Prevent Serious Or Fatal Accidents:

· Be alert at all times; drive forward carefully. People, especially children, can move quickly onto the worksite unnoticed.

· An operator must continuously be aware of all co-workers who share the worksite.

· Backup carefully. An operator must always look to each side and to the rear for co-workers before backing up.

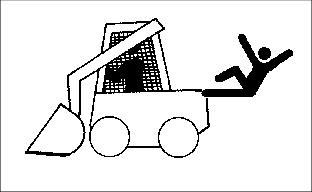

Keep Riders Off

· Allow only the operator on the machine. Keep riders off.

· Riders on the machine or attachment may be struck by foreign objects or thrown off the machine causing serious injury.

· Riders obstruct the operator's view resulting in the machine being operated in an unsafe manner.

Avoid Tipping

· Do not drive where machine could slip or tip.

· Stay alert for holes and other hidden hazards in the terrain.

· Keep away from steep hillsides and drop-offs.

· Slow down before you make a sharp turn or operate on a slope.

· Limit loads to those you can safely control.

· Use counterweights when required per your attachment manual. Carry loads low.

· Drive up and down a hill - not across. Be careful when you change direction on a slope.

· Never drive up or back up a hill or incline with a raised boom.

· If the skid steer should start to tip forward and the boom is raised, immediately lower the boom to regain skid steer stability.

Park Safely

Before removing seat belt and leaving seat:

1. Stop machine on a level surface, not on a slope.

2. Lower boom so attachments are on the ground. (If you must leave boom raised, be sure any attachment is removed and the boom locks are in the locked [Engaged] position, and boom is resting on locks.)

6. Before you leave the operator's seat, wait for engine and all moving parts to stop.

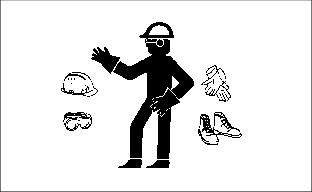

Wear Appropriate Clothing

· Wear close fitting clothing and safety equipment appropriate for the job.

· Loud noise can cause impairment or loss of hearing, wear a suitable protective device such as earplugs.

· Do not wear radio or music headphones while operating the machine. Safe operation requires your full attention.

Check Wheel Bolts

· A serious accident could occur causing serious injury if wheel bolts are not tight.

· Check wheel bolt tightness often during the first 100 hours of operation. Tighten bolts to 169 N·m (125 lb-ft).

Transport Safely

· Avoid personal injury or death resulting from a collision. Use safety lights and devices. Slow moving machines when driven on public roads are hard to see, especially at night.

· Whenever driving on public roads, use flashing warning lights according to local regulations. Additional lights may need to be installed. Machine should also be equipped with a SMV (Slow Moving Vehicle) sign.

· A SMV (Slow Moving Vehicle) sign is available from your Authorized John Deere Skid Steer Dealer.

· A dual flasher kit (four way flasher kit) is available from your Authorized John Deere Skid Steer Dealer.

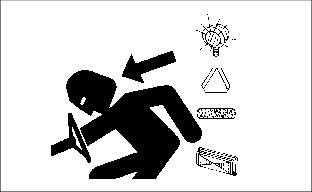

Practice Safe Maintenance

· Do not work under a raised boom unless it is resting on boom locks. Lift arms move near engine hood and frame; never stand or lean on skid steer where linkage can crush you.

· Understand service procedure before doing work. Keep area clean and dry.

· Never lubricate or service machine while it is running. Keep safety devices in place and in working condition. Keep hardware tight.

· To prevent them from getting caught, keep hands, feet, clothing, jewelry, and long hair away from any moving parts.

· Before servicing machine, lower boom and attachment to the ground. Disengage all power. Engage park brake switch (push up). Stop engine. With the seat belt fastened, turn the key switch to the run position (do not start the engine). Disengage the park brake switch (push down). Move boom and bucket pedals back and forth to relieve pressure. Engage park brake switch (push up). Remove the key. Let machine cool.

· Securely support any machine elements that must be raised for service work with safety jack stands or blocks.

· Never run engine unless park brake switch is engaged.

· Keep all parts in good condition and properly installed. Fix damage immediately. Replace worn or broken parts. Remove any buildup of grease, oil, or debris.

· Disconnect battery ground cable (-) before making adjustments on electrical systems or welding on machine.

· Unauthorized modifications to the machine may impair its function and safety.

Handling Waste Product and Chemicals

Waste products, such as, used oil, fuel, coolant, brake fluid, and batteries, can harm the environment and people:

· Do not use beverage containers for waste fluids - someone may drink from them.

· See your local Recycling Center or John Deere dealer to learn how to recycle or get rid of waste products.

· A Material Safety Data Sheet (MSDS) provides specific details on chemical products: physical and health hazards, safety procedures, and emergency response techniques. The seller of the chemical products used with your machine is responsible for providing the MSDS for that product.

Avoid High Pressure Fluids

· Hydraulic hoses and lines can fail due to physical damage, kinks, age, and exposure. Check hoses and lines regularly. Replace damaged hoses and lines.

· Hydraulic fluid connections can loosen due to physical damage and vibration. Check connections regularly. Tighten loose connections.

· Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid the hazard by relieving pressure before disconnecting hydraulic or other lines. Tighten all connections before applying pressure.

· Search for leaks with a piece of cardboard. Protect hands and body from high pressure fluids.

· If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury should reference a knowledgeable medical source. Such information is available from Deere & Company Medical Department in Moline, Illinois, U.S.A. Information may be obtained in the United States and Canada only by calling 1-800-822-8262.

Tire Safety

Explosive separation of a tire and rim parts can cause serious injury or death:

· Do not attempt to mount a tire without the proper equipment and experience to perform the job.

· Always maintain the correct tire pressure. Do not inflate the tires above the recommended pressure. Never weld or heat a wheel and tire assembly. The heat can cause an increase in air pressure resulting in a tire explosion. Welding can structurally weaken or deform the wheel.

· When inflating tires, use a clip-on chuck and extension hose long enough to allow you to stand to one side and not in front of or over the tire assembly.

· Check tires for low pressure, cuts, bubbles, damaged rims or missing lug bolts and nuts.