Introduction

Safety Signs

Controls

Operating

Lawn Care

Replacement Parts

Service Machine Safely

Service Intervals

Service Engine

Service Transmission

Service Steering & Brakes

Service Electrical

Service Miscellaneous

Checking Tire Pressure (Continued)

Tighten Wheel Bolts And Other Hardware

Troubleshooting

Storing Vehicle

Assembly

Specifications

Warranty

John Deere Quality Statement

CopyrightŠ Deere & Company

Service Miscellaneous

Checking Tire Pressure

2. Check tire pressure with an accurate gauge.

Checking Tire Pressure (Continued)

NOTE: ALL REAR TIRES = 16 x 6.50 - 8,

TIRE PRESSURE = 190 (28)

Refueling Machine

ˇ Use Grade No. 2-D fuel at temperatures above 4°C (40°F).

ˇ Use Grade No. 1-D fuel at temperatures below 4°C (40°F).

ˇ Use Grade No. 1-D fuel for all air temperatures at altitudes above 1500 m (5000 ft.).

ˇ For maximum filter life, sediment and water should not be more than 0.10 per cent.

ˇ The cetane number should be 45 minimum. If you operate your machine where air temperatures are normally low or in high altitudes, you may need fuel with a higher cetane number.

ˇ Cloud Point - For cold weather operation, cloud point should be 6°C (10°F) below lowest normal air temperature.

ˇ In winter use special winter fuel or add an anti-gelling compound to fuel to maintain its proper viscosity.

DO NOT use a galvanized container to store diesel fuel.

ˇ Specially coated steel containers made for diesel fuel.

DO NOT use brass-coated containers, brass is an alloy of copper and zinc.

ˇ Remove any trash from top of fuel tank drain area.

ˇ Never use fuel that is stale or has been stored for a long period of time:

Warm Weather: Maximum 60 days.

Cold Weather: Maximum of 90 days.

ˇ Fill fuel tank at the end of each day's operation. This helps to keep condensation out of fuel tank.

1. STOP engine. If engine is hot let

it cool several minutes before you add fuel.

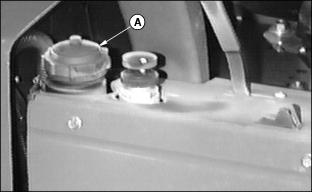

2. Remove fuel tank cap (A) slowly

to allow any pressure built up in tank to escape.

3. Fill tank only to bottom of filler neck.

Filling Fuel Tank (Continued)

F935 (2 Fuel Tanks): 41.6 L (11 U.S. gal)

Fill fuel tank(s) at end of each day's operation or when fuel gauge shows that you are near empty.

Fill fuel tank(s) only to bottom of filler neck.

Fuel Storage

NOTE: Diesel fuels stored for a long time may form gum and plug filters.

Keep fuel in a clean container in a protected area.

Water and sediment MUST BE removed before fuel gets to the engine.

Do not use deicers to remove water from fuel.

Do not depend on fuel filters to remove water.

If possible, install a water separator at storage tank outlet. (See your John Deere dealer for this part.)

Store fuel drum on its side with plug up.

Checking PTO Belt Tension

NOTE: The end of yellow gauge (A) MUST BE aligned with ends of springs (B) for proper belt tension.

2. Tighten nuts (D) equally to get proper belt tension.

3. Tighten nuts (C) against nuts (D).

4. Adjust spring (E) to 21 mm (.84 in).

5. Check PTO belts for wear damage; replace if necessary.

Lubricating the PTO Shaft

1. Lubricate the rear universal joint on the PTO drive shaft by opening access door (A) and rotating PTO driveshaft until grease fitting is pointing upward.

2. Lubricate universal joint on front of PTO drive shaft from front of mower.

Opening Or Closing Hood

Disconnect rubber hold-down to open hood.

Connect rubber hold-down after closing hood.

Cleaning Front Mower

ˇ Never spray water directly against screens or engine openings such as exhaust pipe, air intake screens, or air cleaner.

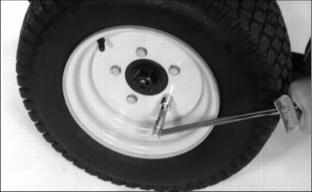

Tighten Wheel Bolts And Other Hardware

Look for loose hardware before each use and check wheel bolts often during operation.

ˇ Front Wheels: 95 Nˇm (70 lb-ft).

Drive Front Mower 30 m (100 ft). Change directions several times as you drive.